Ismerkedjen meg a Liaocheng Xianming 3015 6000w Szál Laser-Vágó Géppel, egy erős és versengő eszközzel, amely tökéletes fém acélcsövek és -lapok pontos és hatékony vágására. Ez a futurisztikus gép tervezve van arra, hogy gyorsabbá és pontosabbá tegye a fémformázási folyamatot

Egy erős 6000w fényimpulzusos laserrel rendelkező vágógép, amely képes különböző fémeket könnyedén elvágni, beleértve az acélt, az alumíniumot, a bronzot és még többet is. A 3015 modell egy 3000mm x 1500mm-es nagy vágóterülettel rendelkezik, ami lehetővé teszi szertejáró projekteken dolgozni.

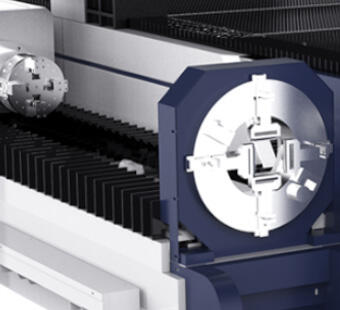

Fényimpulzusos laseres vágógép alkalmazása folytonosan vékony lapokról vastag csövekre, minden esetre alkalmas a fejlettebb vágótechnológiával. A gép forgó tengelyrel van ellátva, amely lehetővé teszi a csövek és rúdok pontos és egyenletes vágását. Ez a funkció kiválóan alkalmas az autóiparban, a repülészeti iparban és az építőiparban.

Magas vágási sebességgel és pontossággal a Liaocheng Xianming 3015 6000w Fiber Laser Cutting Machine tökéletes megoldás a fémvágási igényeidre. Mond hozzá a hosszadalmas és imprecíz konvencionális vágási módszerekhez. Ez a gép nemcsak időt és munka költségeket takarít meg, hanem javít a munkád minőségére.

A felhasználóbarát felület könnyűvé teszi a gép működtetését, akár kezdők számára is. A gép hatékony szoftverrendszerrel rendelkezik, amely lehetővé teszi a vágási minták készítését és szerkesztését egyszerűen. Választható egy széles körű vágási lehetőségek közül, például egyenes vágások, görbék, lyukak és még sok más.

A biztonság első prioritás a Liaocheng Xianming 3015 6000w Szilárdtest Laser Vágógép esetében. A gép biztonsági funkciókkal van ellátva, például sürgősség esetén működő állománygombokkal, védelmi retegekkel és automatikus kikapcsoló érzékelőkkel. Biztosan dolgozhat, tudva, hogy minden potenciális veszélytől védett.

Vevélyezzen be a Liaocheng Xianming 3015 6000w Szilárdtest Laser Vágógépre, és emelje ki a fémformázás új szintjére. Érezze meg a pontos vágás erősségét, és növelje ma már a termelékenységet.

Ez a gép fémlapokat és fémcsöveket is feldolgozhat, jelentősen megtakarítva az igénybevételi költségeket és a tértermet. A cső hossza választható 3 méteres vagy 6 méteres.

A gép fémhajtásos, Nehézfémű ágyalapú szerkezetével biztosítja a deformációmentes működést legfeljebb 20 évre, valamint repülőgépi minőségű alumínium fémből készült sugárrel. stabil működéshez

Ezenkívül az egészen automatikus kétindításos csukló erős és hosszúévű. A gép szintén importált átviteli komponensekkel van ellátva, amelyek nagy pontosságot biztosítanak.

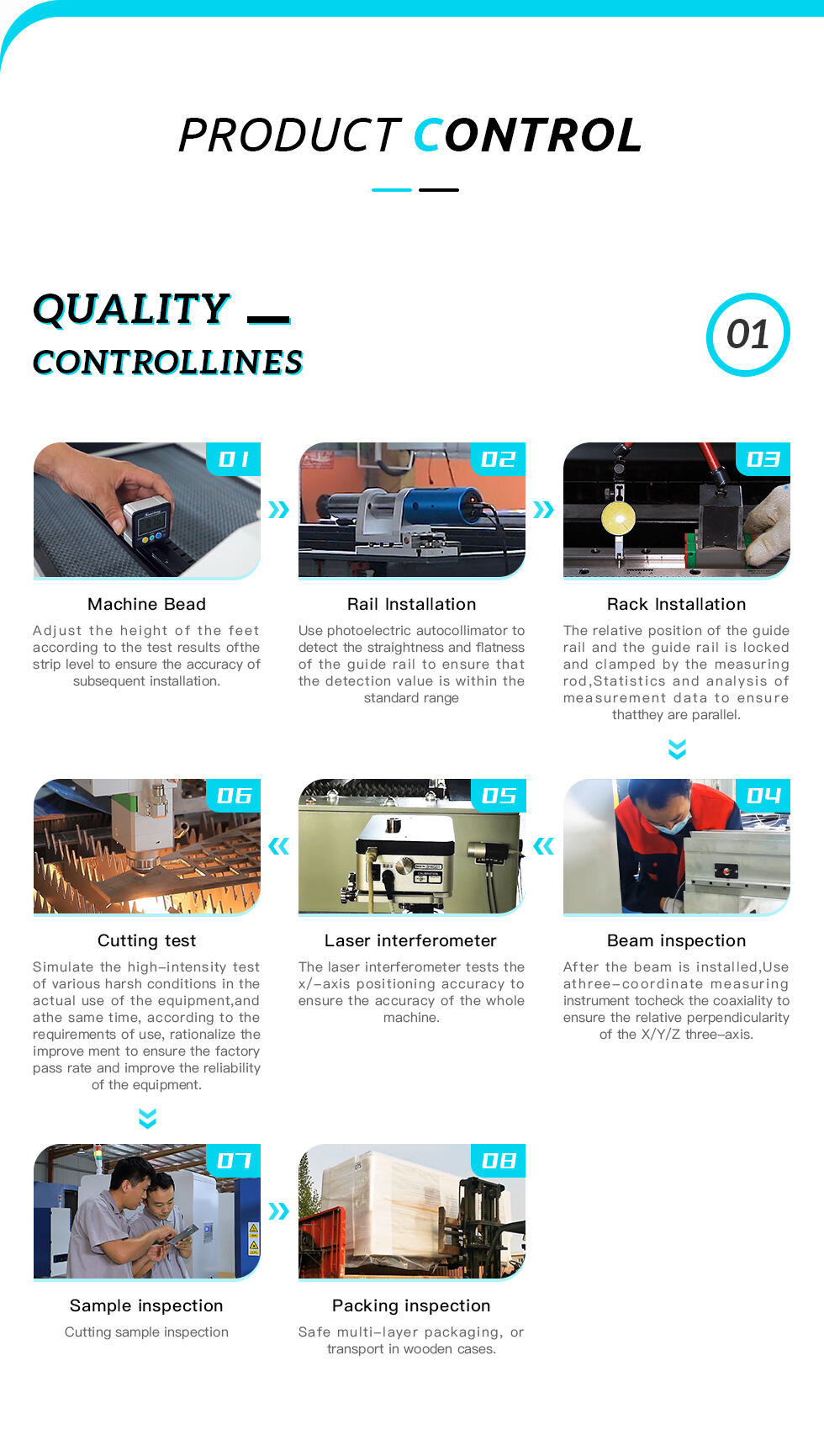

Modell |

XM-3015 |

XM-4015 |

XM-4020 |

XM-6020 |

|

|

|

Munkaterület mm |

3000*1500 |

4000*1500 |

4000*2000 |

6000*2000 |

|

|

|

Lézererő |

1500W/2000W/3000W/6000W/8000W/12000W |

|

|

|

Munkamenet |

Lap és tűz |

|

|

|

Vágófej |

Raytools/Precitec/WSX/OSPRI |

|

|

|

Maximális futási sebesség |

120m/perc |

|

|

|

Lézerforrás |

Max.Raycus.IPG |

|

|

|

Maximális gyorsulás |

1g |

|

|

|

Feszültség |

380V háromfázisú |

|

|

|

Támogatott Grafikus Formátum |

AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT |

|

|

|

CNC RENDSZER |

TubePro & Cypcut |

|

|

|

Egy kattintásnyi nyitás és automatikus középre igazítás csökkenti a betöltésre és kibontásra szükséges várakozási időt. Légiszeres nyitócsukló: nagy és állandó enyhesztési erővel, a nehéz csövet nem mozdulatlanul tartja, amely biztosítja a vágási pontosságot. A speciális támogató rács elkerüli a cső süllyedési deformációját, növeli a vágási pontosságot, és meghosszabbítja a fogásszorító hasznos élettartamát.

Versatil Vágás A laserfej lehetővé teszi a lapok és csövek pontos vágását, biztosítva sima, burkolatmentes szélakaszt.

AUTOFOKUZÁLÁS Automatikus fókusza van rendelkezésre, a laserfej a fókuszt különböző anyagokra és vastagságokra alkalmazza, növelve a vágási hatékonyságot és minőséget.

Magas teljesítmény Stabil magas teljesítményű kimenetet biztosít, amely alkalmas különböző vastagságú fémes anyagok vágására.

Kiváló hűtés Fejlesztett hűtőrendszer biztosítja a laserfej stabil hőmérsékletét hosszabb működési idő alatt, meghosszabbítva az élettartamát.

Hosszútartamú használhatóság Magas minőségű anyagokból és művességből készült, a laserfej hosszú tartósságú státuszt és magas megbízhatóságot garantál. Több anyag kompatibilitás Képes széles körű félműanyagokat vágani, beleértve a szénhférfeszt, rostmentes acélt, alminiumot és rézmetallát, kielégítve a sokféle feldolgozási igényeket.

Moduláris kialakítás Egyszerű, moduláris tervezés miatt a laserfej könnyen karbantartandó és cserélhető, növelve az eszköz karbantartási kényelmét.

Védelmi lencse

Minőségi védőlencsekkal rendelkezik, amelyek hatékonyan megakadályozzák a vágási folyamat során jelentkező dumanypartikula és szórás okozta kártyulásokat.

A TubePro a professionális csővágásra tervezett, támogatja a különféle alakzatú csők és profilkészletezést. Mesterségesen együttműködik a TubesT nesting szoftverrel, hogy standard és speciális termelési igényekhez technikai beállításokat, haladó eszközút-generálást és készletezést valósítson meg.

Automatikus Rúd Középpont Keresés Munkavégző Termelési Darabban és Lebegő Koordináták Hét-Tengelyű Rúd Szállító Rúd Tartó Sarok Technika Aktív Irányítás a Sarok Vágás Korai Béka Ugrása Ingabos Forma Rúd & Profil Termelés

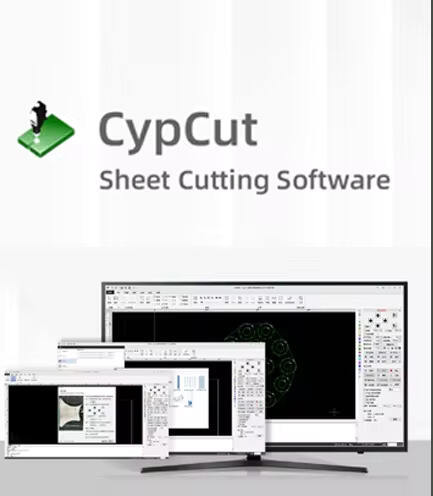

A CypCut lapvágási szoftver egy mélyen kidolgozott tervezés a szilíciumlézer vágási ipar számára. Egyszerűsíti a bonyolult CNC gép műveletet és integrálja a CAD, Nest és CAM modulokat egyetlen programban. A rajzolástól a helyezkedéstől a munkadarab vágásáig mindent pár kattintással lehet befejezni.

Automatikus Bejövő Rajz Optimalizálása

Grafikus Vágási Technika Beállítása

Rugalmas Gyártási Mód

Gyártási Statisztika

Pontos Élszint Találás

Kettős-Üzem Hibaeltolás

A Szakaszokból Összerakott Téglalap alakú Rúdös Ágy

Az ágy belső szerkezete egy repülőgépi anyagú méhcella szerkezet, amely számos téglalap alakú rúddal együtt össze van vívnelve. A rúdok belsőjében található erősítők biztosítják az ágy erősségét és húzódási erőjét, valamint a vezeték támasztójának ellenállását és stabilitását, megakadályozva az deformációt.

Élettartam alatt érvényes szerviz

Biztosítja, hogy a gép pontosan működjön hosszú időre, és nem torzul a használati ideje alatt.

Magas húzóerő, stabilitás és erő, amely lehetővé teszi a 20 éves használatot, anélkül hogy

Az csereasztal kritikus komponens a szilárdtestes laser-vágógépben, két platformból és kapcsolódó automatizálási rendszerekből áll. Ez a funkció lehetővé teszi a műveletvégzőknek, hogy váltson anyagokat a másik platformon a vágási folyamat során, anélkül hogy leállítanák a műveleteket. Az automatikus csereasztal-rendszerrel a műveletvégzők előre felkészíthetik a következő anyagot, lehetővé téve folytonos vágást, az átviteli platform csak 15 másodpercet vesz igénybe egy csereenként, műveleteket, így növelve a termelési hatékonyságot, miközben minimalizálja a leállási időt

K: SEMMIT SEM TUDTAM ERRŐL A GÉPRŐL, MELYIKET VÁLASZTHATNÁM? A: Nagyon egyszerű választani, Csak mondja el nekünk, mit szeretne CNC-lézer géppel elvégezni. Ezután adjunk meg tökéletes megoldásokat és javaslatokat.

K: Mit tud kivágni? Milyen vastagságot tud legfeljebb kivágni?

A: A fémes anyagokra alkalmas lézer gép általában használni a szén-dús acél, rostmentes acél, alu-brasszó és ötvözött anyagokhozon. A maximális vastagság különbözik a modell és az anyag típusától, Kérjük, ellenőrizze az termék bemutató oldalon.

K: Megláthatom gyárjátokat?

A: Természetesen, Kérjük, vegye fel velünk a kapcsolatot bármikor, Előre rendezzük.

Kérdés: Van mérnöke, aki tanít engem/alkalmazottaimat?

Válasz: Igen, minden vásárlónak ingyenes videóképzést kínálunk. Megígérjük, hogy segítünk, amíg mindkét oldalon megerősítetten nem sikerül.