قاطع الليزر الأليافي للمعادن هو أمر رائع بالتأكيد، حيث يزيد ويُكمل عملية قطع ألواح المعادن الرقيقة بعدة طرق. آلة ليزر تنقل العمل المعدني إلى عصر جديد من الدقة والسرعة. أصبح هذا القاطع الليزري بالألياف التكنولوجية فداءً تقنيًا وغيّر العملية الإنتاجية بأكملها، خاصة في المجالات التي يوجد فيها عمل المعادن المستعملة مثل بناء السفن، تصنيع السيارات، الطيران والفضاء، والبناء. ولم يُحدث ثورة فقط في قاطع الليزر الألياف المعدني، بل أعاد بناء معظم أجزاء عملية التصنيع. تم استخدام النفاث المائي لفترة طويلة لقطع الفولاذ ذي الضغط الفائق، وكذلك لقطع المعادن الرئيسية مثل الصلب غير القابل للصدأ، الألمنيوم، النحاس، والبرونز. بعد دمج قواطع الليزر بالألياف، لم يعد هناك حاجة لنظام اليدوي، مما يوفر التكلفة والوقت في عملية تصنيع المعادن. لا حدود لتشغيل قاطع الليزر الألياف، بينما أثناء عملية قطع المعادن، تجلب تقنية الليزر الألياف مستويات غير مسبوقة من الدقة والسرعة. تعزز فرص معالجة المناطق والأشكال دون أخطاء بمساعدة الشعاع المركّز. سرعة الليزر المستخدمة في قواطع الليزر الألياف أسرع من الأخرى، وتقطع المعادن السميك أكثر كفاءة وسرعة. قواطع الليزر الألياف تغيّر كيفية عمل قطاع صناعة المعادن بعدة طرق. أحد المجالات التي تحسنت فيها أنظمة DMLS بشكل كبير هو إنتاج أسرع وأكثر دقة للمكونات المعدنية. كما خفضت قواطع الليزر الألياف الحاجة للحام الجص؛ مما وفر ساعات العمل والتكلفة. التصنيع المستدام للمعادن تم تطويره من خلال تقنية الليزر الألياف. يوفر الصانعون الوقت أثناء إنتاج مكونات معدنية عالية الجودة بسبب القطع السريع لأنواع مختلفة من المعادن كما هو متوقع. هناك أيضًا توفير أكبر في تكاليف العمالة في عملية تصنيع المعادن. عمليات القطع باستخدام قواطع الليزر الألياف تولد نفايات أقل، وبالتالي استدامة أكبر للعملية. إذن، إذا كنت تريد الحصول على قطعة معدنية من قاطع الليزر الألياف، فهي المثالية. إنه شيء رائع للغاية، الذي أحدث تغييرًا هائلًا في هذه الصناعة. قطع المعادن أصبح أكثر سرعة ودقة بالتأكيد، كما أثبت ذلك بفضل قدرته على السرعة والدقة. وقد أظهر أهميته بشكل حاسم في مجالات مثل بناء السفن، تصنيع السيارات، الطيران والفضاء، والبناء.

ولم يقتصر التقدم على مجرد قاطع ليزر ألياف واحد للمعادن، بل أحدث ثورة في تقريباً كل عنصر من عناصر التصنيع. في السابق، استخدمت الشركات المصنعة المياه لقطع المعادن تحت ضغط مرتفع للغاية، بالإضافة إلى قطع مجموعة واسعة من المعادن بما في ذلك الفولاذ المقاوم للصدأ، الألمنيوم، النحاس والبرونز. إنها تكامل بين قواطع الليزر بالألياف التي ألغت تماماً الحاجة إلى الأنظمة اليدوية وأدّت إلى توفير الوقت والتكلفة في عملية تصنيع المعادن.

هناك حدود لما يمكن أن يقوم به المشغل، لكن تقنية ليزر الألياف تجلب مستويات غير مسبوقة من الدقة والسرعة في عمليات قطع المعادن. باستخدام ليزر الألياف، يصبح من السهل جداً معالجة الأشكال المعقدة دون أي أخطاء بسبب الشعاع المركّز. بالإضافة إلى ذلك، فإن سرعة الليزر المستخدمة في قواطع الليزر بالألياف هي أكثر سرعة بكثير مما يسمح بقطع المعادن السميك بشكل سريع وكفء.

بطرق عديدة، تُجبر قطاعات الليزر الأليافية على تحويل كبير في كيفية عمل صناعة معالجة المعادن. الإنتاج الأسرع والأكثر دقة للمكونات المعدنية هو أحد المجالات الرئيسية التي تحسنت فيها أنظمة DMLS بشكل كبير. كما ساعد إنشاء عمليات أقل استهلاكًا للعمل في توفير الوقت والمال في تصنيع المعادن. وأخيرًا، فإن تقليل هدر المواد المرتبط بقطع الليزر الألياف يساعد في نقل تصنيع المعادن نحو عملية أكثر استدامة.

قدّمت تقنية ليزر الألياف تحسينًا كبيرًا في كفاءة واستدامة تصنيع المعادن، مما ثورة الطريقة التي يتم بها ذلك. يسرّع الصانعون من عملية إنشاء مكونات معدنية عن طريق قطع مجموعة واسعة من المعادن بسرعة وبما هو متوقع. كما أن الحاجة الأقل للعمل اليدوي ترتبط بتكلفة عمل أفضل. تنتج أجهزة قطع ليزر الألياف هدرًا أقل مقارنة بعمليات تصنيع المعادن التقليدية، مما يتيح ممارسة أكثر استدامة.

لخصًا، إذا كنت تريد الحصول على جزء من قاطع الليزر الألياف المعدني مثل ذلك فهو شيء رائع، والذي غير هذه الصناعة بشكل قوي. لقد جعل عمليات قطع المعادن أسرع وأكثر دقة ودقة بفضل قدراته المذهلة في الدقة والسرعة. أثبتت قواطع الليزر الألياف أنها ضرورية في الصناعات مثل بناء السفن، وصناعة السيارات، والأerospace والبناء من خلال تحسين العمليات وتقليل الهدر.

لدى لياوتشنغ شيانمينغ وحدة تصنيع مساحتها 30000 متر مربع. نريد أن يكون لدينا قسم تطوير رائد في الصناعة، لذلك ننظر إلى إنشاء أنواع مختلفة من ألياف الليزر.

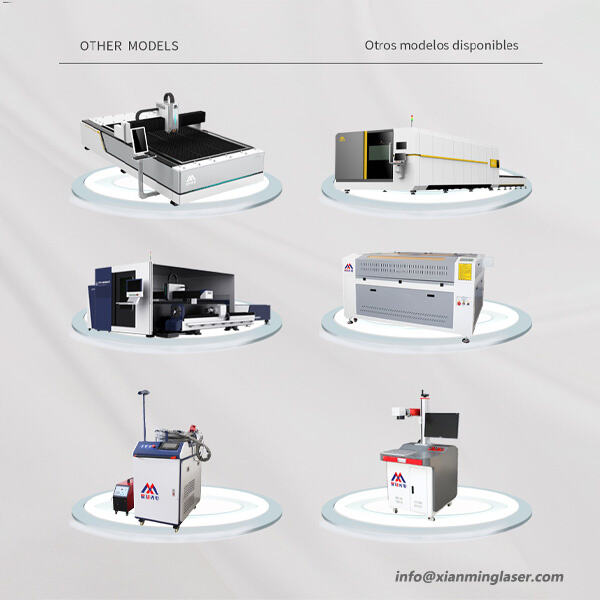

تنتج Liaocheng Xianming للعملاء شعارات مخصصة بالإضافة إلى مقاطع فيديو وصور和其他 مواد. يقدم الوكلاء أيضًا عناصر مخصصة حسب طلب العملاء. تميل أجهزتنا الليزرية للألياف لأن تكون أكثر تقدمًا مقارنة بمعظم المصنعين، تشمل خدماتنا الرئيسية ومنتجاتنا مجموعة واسعة من آلات قطع المعادن ذات القدرة العالية، وأجهزة اللحام بالليزر، وأجهزة التنظيف، وأجهزة النقش بالليزر CO2.

شركة Liaocheng Xianming Machines توفر تغليفًا لوجستيًا محترفًا لتوفير خدمات نقل سريعة وكفوءة للعملاء مما يجعل اللوجستيات أكثر فعالية من حيث التكلفة. سنبذل قصارى جهدنا لضمان وصول ماكينة الليزر الألياف إلى وجهتها بسرعة وبدون مشاكل، سواء كنت فردًا أو شركة.

يلقي لياؤتشينغ شيانمينغ اهتمامًا كبيرًا بالخدمات بعد البيع، عالمين بأن خدمة جيدة لأجهزة الليزر الألياف بالنسبة لنا هي ذات أهمية كبيرة. نلتزم بالمبادئ التي تتماشى مع التركيز على العميل والوجود العالمي. يتم تحقيق ذلك من خلال دعم شبكة الخدمات.

جميع الحقوق محفوظة. © شركة لياوتشنغ شياني밍 ليزر المحدودة. - سياسة الخصوصية-المدونة