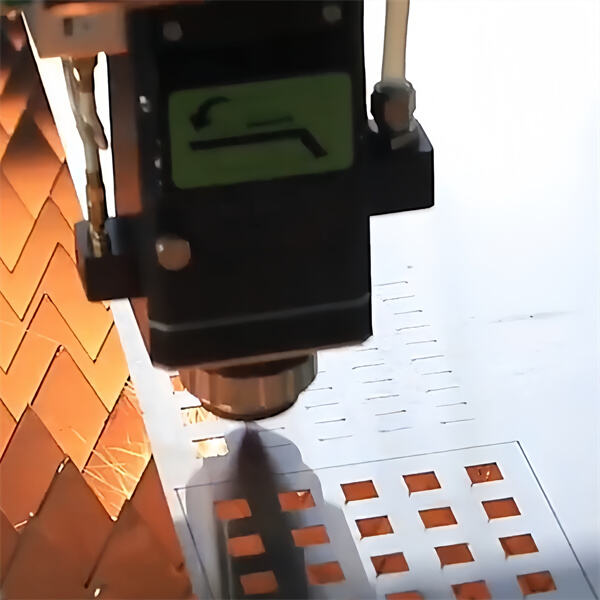

إذا كنت بحاجة إلى تقطيع المعادن، فإن ماكينة القطع بالليزر الألياف هي الخيار المثالي. سواء كنت تدير مصنعًا صناعيًا كبيرًا أو مؤسسة صغيرة، فإن دمج ماكينة القطع بالليزر الألياف في عملية الإنتاج الخاص بك سيرفع مستوى الإنتاجية إلى مستوى آخر. واحدة من الخيارات البارزة هي ماكينة قطع ليزر ألياف قوية بقوة 1500 واط، والتي تبرز لتلبية المتطلبات الكفء في الصناعة. يمكن لهذه الأداة أن تقطع بشكل سلس عبر ألواح معدنية سميكة بكفاءة، وتقدم قطعًا دقيقًا ونظيفًا خلال دقائق. تابع القراءة لمعرفة أهم ميزات هذا المعدات المتقدمة والفائدة منها.

دقة غير مسبوقة في قطع المعادن - تتيح التكنولوجيا الابتكارية للمachine قطع الليزر الأليافي بقوة 1500 واط تقديم دقة عالية المستوى عند العمل مع المعادن. باستخدام شعاع ليزري شديد الكثافة، فإنه يذيب ويتبخر المادة المعدنية لإنتاج قطع دقيقة وخالية تمامًا من التشوهات. هذا يغني عن عمليات التشطيب الإضافية مثل الصقل أو الطحن، مما يوفر لك الوقت والموارد الثمينة. بالإضافة إلى ذلك، فإن الجهاز متعدد الاستخدامات ويمكن استخدامه مع أنواع مختلفة من المعادن مثل الفولاذ، والألومنيوم، والنحاس، والبرونز وما إلى ذلك، بسمك يتراوح من بضعة مليمترات إلى عدة سنتيمترات.

مصممة خصيصًا للاستخدام الصناعي: جهاز قطع الليزر بقوة 1500 واط مصمم ومُحسّن ليُستخدم في البيئات المستندة إلى الصناعة مع التركيز على الإنتاجية والكفاءة. يمكن للشعاع البلازما قطع ألواح المعدن السميكة في ثوانٍ معدودة - مناسب تمامًا للإنتاج العالي الحجم. توفر هذه الآلة الحاصلة على براءة اختراع مستوى عالٍ من التلقائيّة مع برامج التعامل مع المواد والتداخل لتقليل زمن الإعداد وتقليل هدر المواد. بالإضافة إلى ذلك، فإن تشغيلها المستمر يُلغي الحاجة للصيانة المتكررة مما يؤدي إلى تقليل وقت التوقف عن العمل.

آلة قطع الليزر الأليافية بقوة 1500 واط هي أسرع آلة قطع في فئتها، حيث تأتي مع قدرة قص عالية السرعة كميزة قياسية. هناك تفسيران موجودان في الخلف. بسبب إخراجها العالي للطاقة ونظام التحكم الرقمي بالكامل، يمكنها الوصول إلى سرعة قص قصوى تبلغ 120 مترًا في الدقيقة. يسمح هذا الإيقاع السريع بإكمال المشاريع في جزء من الوقت المطلوب بواسطة طرق القطع الأخرى. بالإضافة إلى ذلك، فإن ميزة التركيز التلقائي لهذه الآلة تحافظ على قطع شعاع الليزر في خط أكثر حدة ودقة، مما يقلل من الهدر.

خيار اقتصادي مناسب للشركات الصغيرة: قد يبدو السعر الأولي لامتلاك ماكنة قص ليزر ألياف بقوة 1500 واط مرتفعًا، لكن في الواقع سيوفر المال مع مرور الوقت. تكلفة تشغيل ماكنة الليزر الألياف منخفضة وهي استثمار حقيقي، على عكس البلازما أو ماكينات الماء التي قد تبدو أرخص في البداية ولكنها تتعطل بسرعة. بالإضافة إلى ذلك، فإن كفاءتها في تنفيذ مجموعة متنوعة من مهام القطع تجعل الحاجة إلى استخدام معدات متعددة غير ضرورية، مما يوفر المساحة والتكاليف الرأسمالية.

تم تحسين هذه الآلات بشكل كبير على مر السنين لتقديم أداء قطع أفضل وللقضاء على الحاجة إلى إزالة الحواف البارزة. النماذج الجديدة المتوفرة لا تحتوي على أي نوع من المستشعرات التي يمكنها الكشف عن السطح والعمل بناءً على نوع الاستشعار الراسم الكهربائي للمسافات على سطح المادة، بعيدًا عن منطقة التركيز الخاصة بها. وهذا يعني أن الليزر كان دائمًا في مكان مثالي جدًا، مما يجعل القطع أكثر نظافة ودقة. يتم تقديم منطقة القطع باستخدام النيتروجين لإنشاء الانتهاء المطلوب - وهو ممتاز بشكل خاص للفولاذ المقاوم للصدأ. يمكن أيضًا استخدام النيتروجين كخاصية مساعدة بالغاز على الآلات، حيث يقوم بتفجير كميات دقيقة من الغازات حول منطقة القطع لتجنب الأكسدة والحواف البارزة عند العمل مع هذه المواد.

بالمجمل، الحصول على نظام تقطيع ليزر ألياف بقوة 1500 واط هو استثمار مثالي لأي شركة تصنيع معادن. فهو يتميز بدقة لا مثيل لها، وكفاءة صناعية وسرعة محتملة بفضل تكلفته المعقولة (حيث يُعتبر حالياً أقل الطرق تكلفة)، ويمكن أن يوفر لشركتك الكثير من المال ويقدم قدرة تقطيع عالية السرعة؛ مما يجعل تحقيق إنتاجية أعلى وأداء العمل أسهل.

شبكة أسواق ومبيعات أجهزة شيانمينغ لياوتشنغ التي تمتد عبر أكثر من 60 دولة ومنطقة. لديها إجراءات لوجستية محترفة توفر للعملاء خدمات نقل سريعة، مما يضمن أن تكون العمليات اللوجستية أكثر كفاءة. سنحاول قصارى جهدنا لضمان وصول آلة الليزر الألياف إلى وجهتها بسرعة وأمان، سواء كنت عميلًا للأعمال التجارية أم لا.

يلقي لياؤتشينغ شيانمينغ اهتمامًا كبيرًا بالخدمات بعد البيع، عالمين بأن خدمة جيدة لأجهزة الليزر الألياف بالنسبة لنا هي ذات أهمية كبيرة. نلتزم بالمبادئ التي تتماشى مع التركيز على العميل والوجود العالمي. يتم تحقيق ذلك من خلال دعم شبكة الخدمات.

تتمتع شركة لياوتشنغ شيانمينغ بالقدرة على تقديم العملاء بشعار أيضًا لأن هناك خدمات شخصية أخرى وكلاء يمكنهم وضع شعار العميل على صور المنتجات ومقاطع الفيديو بالإضافة إلى منتجات أخرى. تعتبر آلة القطع بالليزر الألياف أفضل من الشركات المصنعة الأخرى.

تغطي Liaocheng Xianming عنصر 30000 متر مربع داخل المصنع ولديها الآن فريق رائد في المجال، وتتركز في تطوير وإنشاء أنواع مختلفة من ماكينات ليزر الألياف. لقد حصلنا على براءات اختراع عديدة وحصلنا أيضًا على شهادة إدارة الجودة IS09001 وكذلك شهادة CE الأوروبية وشهادة FDA.

جميع الحقوق محفوظة. © شركة لياوتشنغ شياني밍 ليزر المحدودة. - سياسة الخصوصية-المدونة