Xianming Laser tərəfindən Lif Lazer Avadanlıqlarının Şkivorunun Təmiri üzrə Təlimat

Sizin lazer Kəsmə Maşını avtomatik işləməsini və uzunmüddətli performansını təmin etmək üçün soyutma cihazının müntəzəm təmiri vacibdir. Xianming Laser avadanlığınızı elmi üsulla təmir etməyinizə kömək edəcək ətraflı təlimatlar hazırlayıb və sizin fiber lazer avadanlıqları səmərəli və etibarlı şəkildə işləməsini təmin edir.

Yazlıqlar üçün idman

Yazlıqlar üçün idman

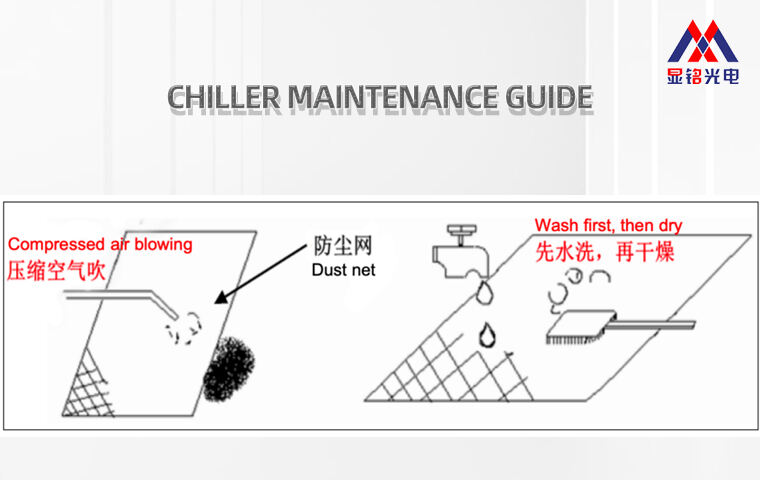

Soyuducunun kondensatorunu və toz filtrini təxminən hər 15 günde bir təmizləmək məsləhət görülür.

Soyuma lövhələrinə zərər verməmək üçün təmizləmək üçün hava tabancası və ya yumşaq fırça istifadə edin.

Qışda Donmadan Qorunma və Uzunmüddətli Saxlama

Qışda Donmadan Qorunma və Uzunmüddətli Saxlama

Avadanlığın daşınması zamanı və ya uzun müddət istifadə olunmadığı hallarda, suyu rezervuardan boşaltma valfı vasitəsilə boşaldın.

Nasosun daxilində qalan suyu çıxarmaq üçün nasosun altındakı boşaltma tapasını gevşedin.

Gecənin temperaturu 2°C-dən aşağı düşərsə, zədələnməni qarşısını almaq üçün soyuducunu işlədilməsini davam etdirmək və ya antifriz əlavə etmək məsləhət görülür.

Çıxış Filtrinin Təmizlənməsi

Çıxış Filtrinin Təmizlənməsi

İdarəetmə panelinin yanındakı sol tərəf panelini açın və Y tipli filtrin yerini müəyyən edin.

Filter torunu çıxarmaq üçün çiyçığı sola doğru (saat əqrəbinin əksinə) döndərərək anahtar istifadə edin.

Zibilin çıxarılması üçün filteri hava qabı veya su ilə tamamilə təmizləyin.

Təmizlədikdən sonra çiyçağı sağa doğru (saat əqrəbi istiqamətində) döndərərək anahtarla sıxın.

Saf Su və ya Deionlaşdırılmış Su ilə Əvəz Etmək

Saf Su və ya Deionlaşdırılmış Su ilə Əvəz Etmək

Soyuducudan antifrizi çıxarmaq üçün boşaltma valfini açın.

Boşaltma valfini bağlayın, doldurma deliğindən saf su və ya deionlaşdırılmış su əlavə edin və qalan antifrizi azaltmaq üçün soyuducusu işə salın.

Nəhəng antifrizi yenidən boşaltma valfindən çıxarın. Bu addımı 2–3 dəfə təkrarlayın.

Nəhayət, ekran üzərindəki yaşıl zonaya çatana qədər səviyyəsinə çatana qədər saf su və ya deionlaşdırılmış su əlavə edin.

Günlük Təmir Qeydləri

Günlük Təmir Qeydləri

Təmirdən hər dəfə zədələnmiş hissələrin dərhal əvəz edilməsi lazımdır.

Bu, soyuducunu qoruyan deyil, həm də lazer kəsici maşınının optimal kəsmə performansını təmin edir.

Soyuducunun təmiri avadanlığın özü üçün mühafizə deyil, eyni zamanda lifli lazer avadanlığının davamlı və səmərəli işləməsinin əsasıdır. Həm lift lazer qaynaq maşını həm də lifli lazer kəsici sistemi üçün filtrlərin müntəzəm təmizlənməsi, dondurucunun boşaldılması və təmiz suyun doldurulması avadanlıq ömrünü uzada və emal keyfiyyətini yaxşılaşdıra bilər. Davamlı, elmi təmirlə lazer texnologiyası istehsalınızda maksimum dəyər verə bilər.