Technology

-

Xianming Laser Welding Wire Feeding Selection Guide Based on Laser Power

2026/01/30In laser welding applications, the wire feeding configuration plays a critical role in welding quality, penetration depth, and production efficiency. Selecting the right wire feeding system according to laser power and application requirements helps achieve stable welds and higher productivity.

-

Xianming Laser Welding Machine Power Selection Guide

2026/01/29Choosing the right laser welding machine is key to achieving high-quality laser welds, efficient production, and reliable performance. At Xianming Laser, we’ve compiled a straightforward selection guide to help you match your application needs with the right laser power.

-

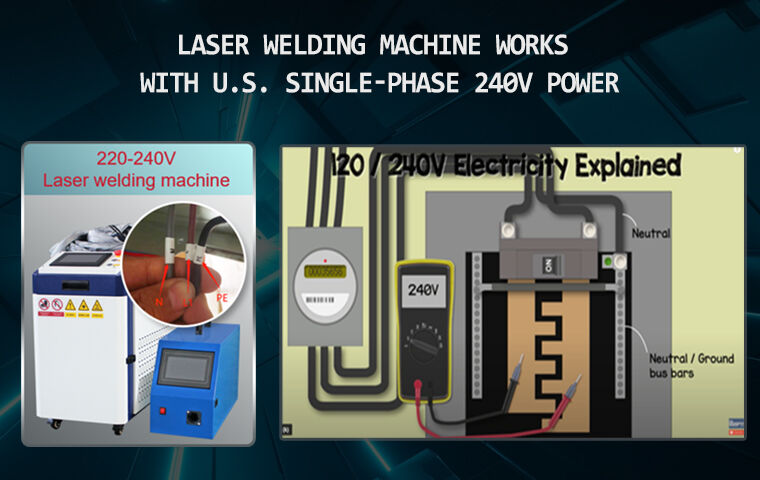

Why 220–240V Laser Welding Machines Work Perfectly in the United States

2026/01/28When purchasing and installing a laser welding machine, power compatibility is one of the most common concerns for customers in the United States

-

The Importance of Laser Safety Glasses in Laser Welding Machine Operations

2026/01/27With the rapid development of laser technology, laser processing has become a core solution in modern manufacturing. Laser welding machines are widely used in metal fabrication, automotive components, and precision manufacturing due to their high efficiency and stable welding quality.

-

The Role and Importance of Safety Clamps in Laser Welding Machines

2026/01/24In Xianming Laser handheld fiber laser welding machines and other laser equipment operations, safety is always the top priority. Safety clamps are essential auxiliary devices that not only protect operators but also enhance welding efficiency and weld quality, making them a key component of Xianming Laser’s high-precision welding solutions.

-

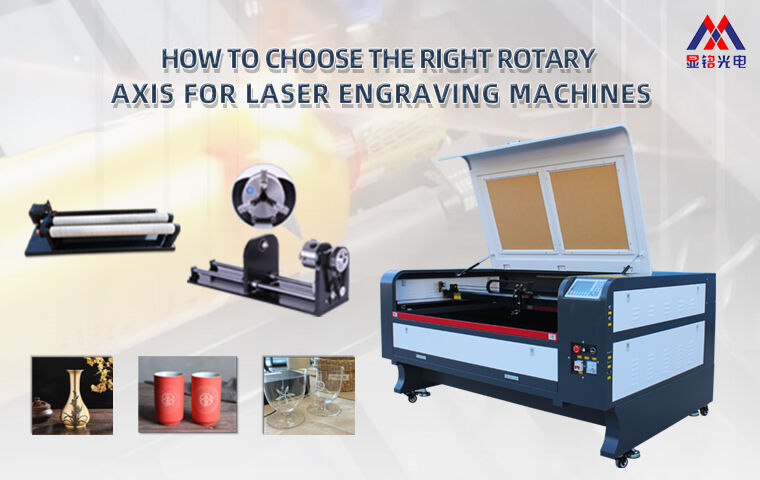

How to Choose the Right Rotary Axis for Laser Engraving Machines

2026/01/23In laser engraving and laser marking applications, a rotary axis is an essential accessory for processing cylindrical and round objects. Choosing the right rotary axis based on engraving accuracy, workpiece type, and budget can significantly improve processing efficiency while controlling overall costs.

-

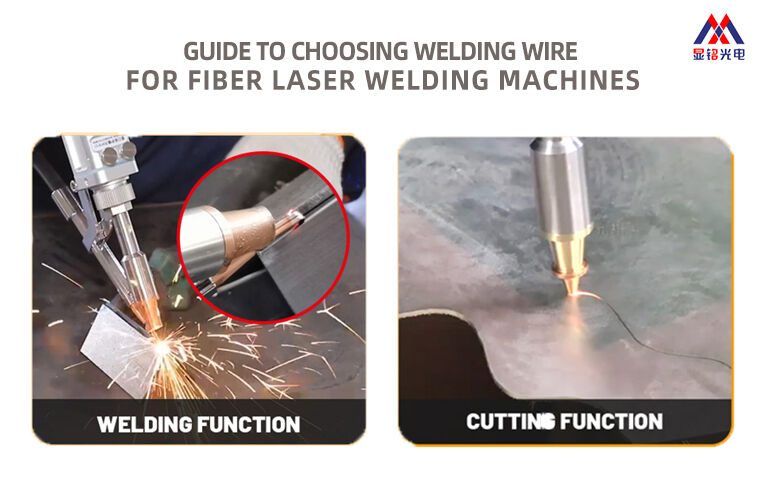

Guide to Choosing Welding Wire for Fiber Laser Welding Machines

2026/01/22In laser welding processes, welding wire is a critical filler material that directly affects weld appearance, joint strength, and overall welding quality. Selecting the right welding wire helps improve welding stability while reducing common defects such as spatter and porosity. This article explains key principles for choosing welding wire for laser welding machines.

-

Standard Startup Procedure for Fiber Laser Welding Machines

2026/01/21Laser welding machines integrate multiple core modules, including the laser source, water chiller, gas supply system, and wire feeder. At Xianming Laser, we believe that following a standardized startup sequence together with correct operating parameters is essential to ensure safe and stable machine operation, consistent welding quality, and extended service life of key components. Below is the standard startup procedure and parameter guidelines for portable fiber laser welding machine.

-

Xianming Laser Welding Machines – Single-Swing vs Dual-Swing Welding System Technical Guide

2026/01/17As a professional manufacturer of laser welding equipment, Xianming Laser offers two mature solutions for different industry applications and welding conditions: single-swing welding machine and dual-swing welding machine. Both are designed to help customers achieve the optimal balance between welding quality, system stability, and operational efficiency.

-

Common Shielding Gases for Fiber Laser Welding Machines and Their Functions

2026/01/15In the laser welding process, shielding gas does not directly participate in welding, but it plays a crucial role in weld quality, seam formation, and equipment stability. Proper selection and use of shielding gas can effectively improve welding performance and reduce defect rates. This article introduces the common gases used in laser welding machines and explains their specific functions.