NEWS

-

Air Cooled Laser Welding Machine Rise Leading Lightweight High Efficiency Welding Trend

2026/02/06As manufacturers continue pursuing higher efficiency, lower operating costs, and more flexible production methods, traditional water-cooled laser welding machines are gradually revealing their limitations. Complex installation, bulky structures, demanding maintenance, and high energy consumption make them less suitable for modern processing environments.

-

Air-Cooled vs Water-Cooled Laser Welding Machines: Differences and Applications

2026/02/05In modern industrial production, laser welding machines have become essential equipment for metal fabrication. When choosing a laser welding machine, one key factor is the cooling method.

-

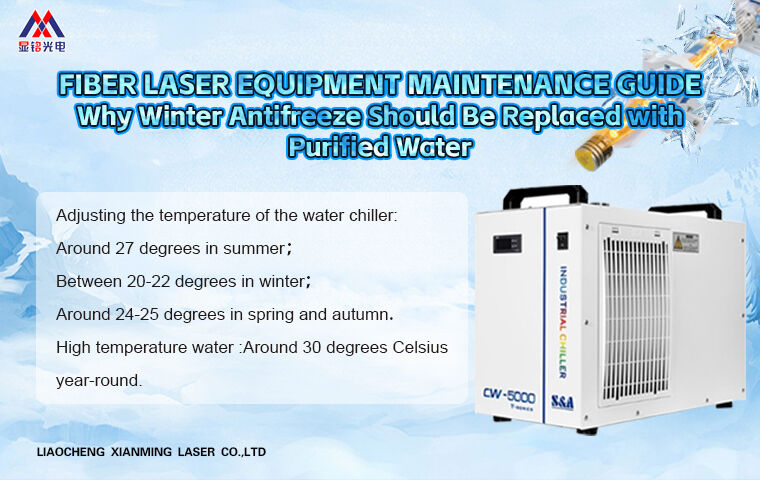

Fiber Laser Equipment Maintenance Guide: Why Winter Antifreeze Should Be Replaced with Purified Water

2026/02/04Attention all operators: After winter, it is essential to replace the antifreeze in your fiber laser cutting machines and fiber laser welding machines with purified water. Failing to do so may reduce cooling efficiency, affect performance, and shorten the lifespan of your laser equipment. Follow the instructions below to maintain your equipment properly.

-

Fiber Laser Welding Machine Maintenance Guide

2026/02/04In daily use of a fiber laser welding machine, the stability and performance of the equipment depend not only on the laser source and control system but also on proper maintenance of key optical components. Among them, the protective lens is one of the most critical consumable parts, directly affecting laser transmission efficiency and welding quality.

-

Fiber Laser Welding Machine Laser Activation Guide: Unlocking Your Laser Equipment

2026/02/03Proper activation of a fiber laser welding machine is essential to ensure stable laser output, reliable performance, and safe operation. At Xianming Laser, we provide clear guidance on how to activate your laser system quickly and efficiently, helping users get started with confidence.

-

Fiber Laser Welding Machine Troubleshooting Guide for Metal Welding Applications

2026/02/14In daily metal fabrication, a fiber laser welding machine is designed to run continuously with high precision and efficiency. With proper operation and routine maintenance, the system can maintain long-term stable performance and consistent welding quality.

-

Proper Shutdown Procedure for a Fiber Laser Welding Machine

2026/02/03Correct operation habits are as important as welding skills. Improper shutdown can shorten component life, damage optics, or create safety risks.Whether using a standard unit or a laser welding machine 4 in 1, following a standardized shutdown sequence protects the laser source, cooling system, and welding head, ensuring long-term stability and consistent welding quality.

-

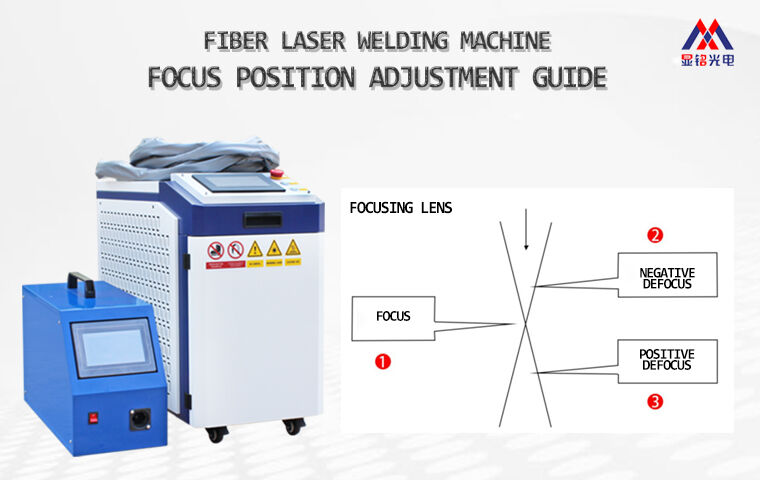

Fiber Laser Welding Machine Focus Position Adjustment Guide

2026/02/02In laser welding applications, focus position adjustment plays a critical role in determining weld penetration, spot size, energy density, and overall weld quality.A correct focal setting can significantly reduce spatter, prevent burn-through, and ensure stable, consistent weld seams.

-

Xianming Laser Welding Wire Feeding Selection Guide Based on Laser Power

2026/01/30In laser welding applications, the wire feeding configuration plays a critical role in welding quality, penetration depth, and production efficiency. Selecting the right wire feeding system according to laser power and application requirements helps achieve stable welds and higher productivity.

-

Xianming Laser Welding Machine Power Selection Guide

2026/01/29Choosing the right laser welding machine is key to achieving high-quality laser welds, efficient production, and reliable performance. At Xianming Laser, we’ve compiled a straightforward selection guide to help you match your application needs with the right laser power.