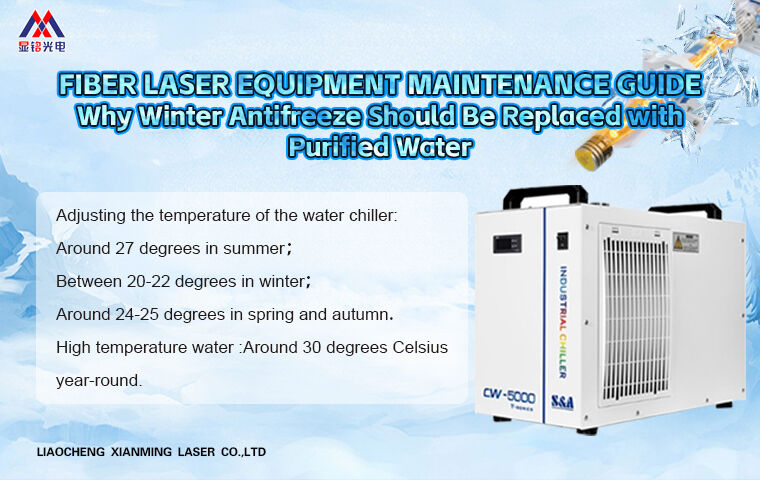

Fiber Laser Equipment Maintenance Guide: Why Winter Antifreeze Should Be Replaced with Purified Water

Attention all operators: After winter, it is essential to replace the antifreeze in your fiber laser cutting machines and fiber laser welding machines with purified water. Failing to do so may reduce cooling efficiency, affect performance, and shorten the lifespan of your laser equipment. Follow the instructions below to maintain your equipment properly.

⚠️ Why You Must Replace Antifreeze

Antifreeze can reduce cooling efficiency in warm seasons

Antifreeze can reduce cooling efficiency in warm seasons

Antifreeze used in winter has lower thermal conductivity than purified water. Continuing to circulate it during spring and summer can lower cooling efficiency, affecting welding and cutting quality.

Prevent chemical deposits and corrosion

Prevent chemical deposits and corrosion

Winter antifreeze contains additives that may leave residues in pipes, cooling heads, or pumps if left circulating at normal temperatures. This can cause corrosion or damage sensitive components in your laser equipment.

Avoid expansion pressure from temperature changes

Avoid expansion pressure from temperature changes

High-concentration antifreeze expands more when heated. Long-term circulation in warm weather may increase pressure on pipelines or pumps, potentially damaging seals.

🔧 Recommended Procedure

Turn off the laser equipment to ensure safety.

Drain the antifreeze completely; do not directly add purified water over old fluid.

Flush the system with purified water to remove any residues from pipes and cooling heads.

Refill the system with purified water to the appropriate level.

Remove any air from the circulation to ensure smooth flow.

Check water quality regularly. If the equipment will be idle for a long time, a small amount of corrosion inhibitor can be added.

✅ Practical Reminders

Antifreeze is only needed for low-temperature protection; in spring and summer, always switch to purified water.

Perform flushing in a clean environment to prevent debris from entering the system.

Maintain purified water cleanliness and replace it periodically to protect the cooling system and your laser equipment.

💡 Key Takeaway:

Winter antifreeze protects your fiber laser cutting and welding machines from freezing, but purified water ensures optimal cooling in warmer months. Always follow seasonal maintenance guidelines provided by Xianming Laser to keep your equipment safe, efficient, and long-lasting.