Le découpeur laser à fibre pour le métal est incroyable, c'est certain, car il améliore et perfectionne le processus de découpe des tôles minces de plusieurs manières. Une machine laser qui transporte l'usinage du métal vers une nouvelle ère de précision et de vitesse. Ce découpeur laser à fibre métallique est devenu une rédemption technologique et a transformé l'ensemble du processus de fabrication, en particulier dans les domaines où l'usinage du métal recyclé existe, comme la construction navale, la fabrication automobile, l'aérospatial et la construction. Et ce n'est pas seulement un découpeur laser à fibre métallique qui a été révolutionné, presque toutes les parties du processus de fabrication ont été restructurées. La découpe au jet d'eau a longtemps été utilisée pour découper des métaux sous haute pression, tels que l'acier de cours de travail métallique, ainsi que pour découper des métaux majeurs comme l'acier inoxydable, l'aluminium, le laiton et le cuivre. Après l'intégration des découpeurs laser à fibre, il n'y a plus besoin de ce système manuel, ce qui économise du temps et des coûts dans le processus de fabrication métallique. Il n'y a aucune limite pour l'opérateur d'un découpeur laser à fibre, tandis que dans le processus de découpe métallique, la technologie laser à fibre apporte des niveaux sans précédent de précision et de vitesse. Elle renforce les chances de traiter des zones et des formes sans erreurs grâce au faisceau focalisé. La vitesse du laser utilisée dans les découpeurs laser à fibre est plus rapide que les autres, et elle coupe les métaux épais plus rapidement et efficacement. Les découpeurs laser à fibre revolutionnent la manière dont le secteur de l'usinage du métal opère de nombreuses façons. Un domaine dans lequel les systèmes DMLS ont considérablement amélioré le processus de fabrication est la production plus rapide et plus précise de composants métalliques. Les découpeurs laser à fibre ont également réduit le besoin de soudage par plâtrage ; les producteurs ont économisé des dizaines d'heures de main-d'œuvre et de coût. Fabrication métallique durable développée grâce à la technologie laser à fibre. Les fabricants gagnent du temps lors de la production de composants métalliques de haute qualité grâce à une découpe rapide de divers métaux comme prévu. Il y a également des économies améliorées de coûts de main-d'œuvre dans le processus de fabrication métallique. Les opérations de découpe des découpeurs laser à fibre génèrent moins de déchets, rendant ainsi l'opération plus durable. Donc, si vous voulez obtenir une pièce métallique d'un découpeur laser à fibre, c'est celle idéale. C'est quelque chose de super incroyable, qui a eu un changement puissant dans cette industrie. La découpe du métal est devenue encore plus rapide et plus précise, c'est certain, comme elle l'a prouvé simplement par sa capacité de vitesse et de précision. Elle s'est avérée cruciale dans des domaines tels que la construction navale, la fabrication automobile, l'aérospatial et la construction.

Et l'avancée ne se limite pas à un seul découpeur laser à fibre, au contraire, elle a réformé presque tous les éléments de la fabrication. Précédemment, les fabricants utilisaient l'eau pour découper du métal sous une pression extrêmement élevée, ainsi que pour couper une large gamme de métaux, y compris l'acier inoxydable, l'aluminium, le laiton et le cuivre. Ce sont des intégrations de découpeurs lasers à fibre, qui ont complètement éliminé les besoins en systèmes manuels et ont économisé du temps et des coûts dans le processus de fabrication métallique.

Un opérateur ne peut faire qu'un certain nombre de choses, mais la technologie laser à fibre apporte des niveaux sans précédent de précision et de rapidité aux opérations de découpe métallique. Avec un laser à fibre, il est encore plus simple de traiter des formes complexes sans erreurs grâce au faisceau focalisé. De plus, la vitesse du laser utilisé dans les découpeurs laser à fibre est plus rapide pour découper efficacement et rapidement des métaux épais.

De nombreuses manières, les découpeurs au laser à fibre forcent un changement massif dans la façon dont l'industrie de la mécanique opère. Une production plus rapide et plus précise des composants en métal est l'un des principaux domaines dans lesquels les systèmes DMLS ont considérablement amélioré. La création de processus moins intensifs en main-d'œuvre a également aidé à économiser du temps et de l'argent dans la fabrication de métaux. Enfin, la réduction des déchets liés aux découpeurs au laser à fibre aide à rendre la fabrication de métaux plus durable.

La technologie laser à fibre a considérablement amélioré l'efficacité et la durabilité de la fabrication des métaux, révolutionnant ainsi cette pratique. Les fabricants accélèrent le processus de création de composants en métal en perçant rapidement à travers une gamme de métaux de manière prévisible. Le besoin réduit de travail manuel correspond également à un meilleur coût de main-d'œuvre. Les découpeurs au laser à fibre produisent moins de déchets que les opérations conventionnelles de fabrication de métaux, permettant ainsi une pratique plus durable.

En résumé, si vous voulez avoir une partie de l'incroyable coupe-laser par fibre pour le métal, qui a tellement transformé cette industrie avec une telle puissance. Il a rendu les processus de découpe du métal encore plus rapides, précis et exacts grâce à ses capacités incroyables en termes de précision et de vitesse. Les découpeuses laser à fibre ont prouvé qu'elles sont essentielles dans des industries comme la construction navale, la fabrication automobile, l'aérospatiale et la construction, en optimisant les opérations et en réduisant les déchets.

Liaocheng Xianming dispose d'une unité de fabrication de 30000m². Nous voulons avoir le meilleur département R&D de l'industrie, c'est pourquoi nous nous concentrons sur la création de divers types de lasers à fibres.

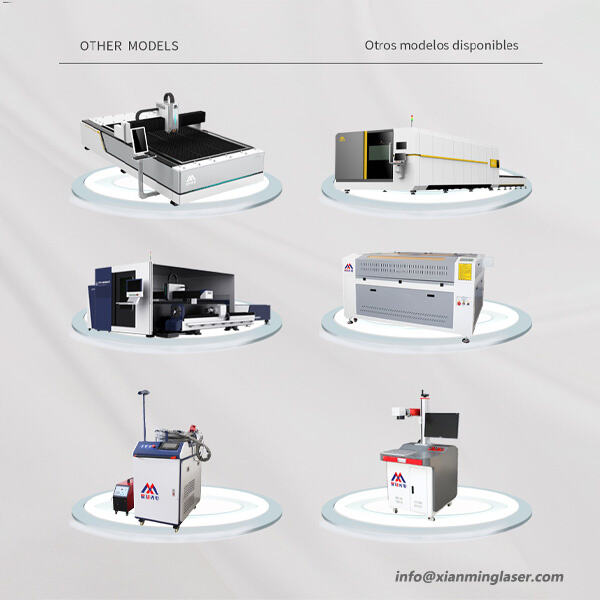

Liaocheng Xianming fournit des clients avec des logos personnalisés ainsi que des vidéos, images et autres matériaux. Les agents fournissent également des articles sur mesure selon les besoins des clients. Nos machines à fibres laser sont plus avancées que celles de nombreux fabricants ; nos principaux services et produits incluent une large gamme de machines de découpe laser métallique haute puissance, machine de soudage laser, machine de nettoyage, et machine d'usinage au CO2, machine de marquage.

Liaocheng Xianming Machines propose un emballage logistique professionnel pour fournir des services de transport rapides et efficaces aux clients, ce qui rend la logistique plus rentable. Nous ferons de notre mieux pour nous assurer que la machine au laser à fibre arrive rapidement et correctement à destination, quels que soient vos besoins, qu'il s'agisse d'un usage personnel ou commercial.

Liaocheng Xianming accorde beaucoup d'importance aux services après-vente, sachant qu'un bon service pour les machines à laser à fibre est également crucial. Nous nous engageons à suivre des principes axés sur le client et une présence mondiale. Cela est rendu possible grâce au soutien du réseau de service.

Droits d'auteur © Liaocheng Xianming Laser Co., Ltd. Tous droits réservés. - Politique de confidentialité-Blog