Przewodnik po wyborze i wymianie dysz do przecinarek laserowych włóknowych

W cięcie laserowe włókien , dysze mogą być niewielkie, ale mają bezpośredni wpływ na jakość cięcia i żywotność urządzenia. Wybór odpowiedniej dyszy oraz jej untowalna wymiana są kluczowe dla zapewnienia efektywnej i stabilnej pracy. W tym artykule przeprowadzimy Cię przez funkcje, metody doboru oraz kroki wymiany dysz, pomagając osiągnąć optymalne wyniki cięcia.

Główne funkcje dyszy

Główne funkcje dyszy

Dysze odgrywają kluczową rolę w procesie cięcia laserem włóknowym:

Zapobiegają odbijaniu się stopionego materiału i pozostałości do głowicy tnącej oraz chronią obiektyw przed uszkodzeniem;

Skupiają strumień gazu pomocniczego i kontrolują zakres jego rozpraszania oraz prędkość, poprawiając jakość i precyzję cięcia.

Związek pomiędzy dyszą a jakością cięcia

Związek pomiędzy dyszą a jakością cięcia

Każda odkształcona część lub pozostałość w dyszy może wpłynąć na wydajność cięcia, powodując nierówne krawędzie lub niekompletne cięcia. Dlatego konieczne jest regularne czyszczenie dyszy oraz ich natychmiastowa wymiana w przypadku wykrycia jakichkolwiek usterek, aby zapewnić stałą jakość obróbki.

Wybór dyszka

Wybór dyszka

Według średnicy

Według średnicy

Dysze o małej średnicy: wysoka prędkość gazu, silne usuwanie stopionego materiału, odpowiednie do cięcia cienkich blach i uzyskiwania precyzyjnych krawędzi.

Dysze o dużej średnicy: niższa prędkość gazu, słabsze usuwanie stopionego materiału, odpowiednie do niskoprędkościowego cięcia grubych blach. Użycie dyszy o dużej średnicy do cięcia cienkich blach z dużą prędkością może spowodować rozpryskiwanie się materiału i uszkodzenie soczewek ochronnych.

Według typu

Według typu

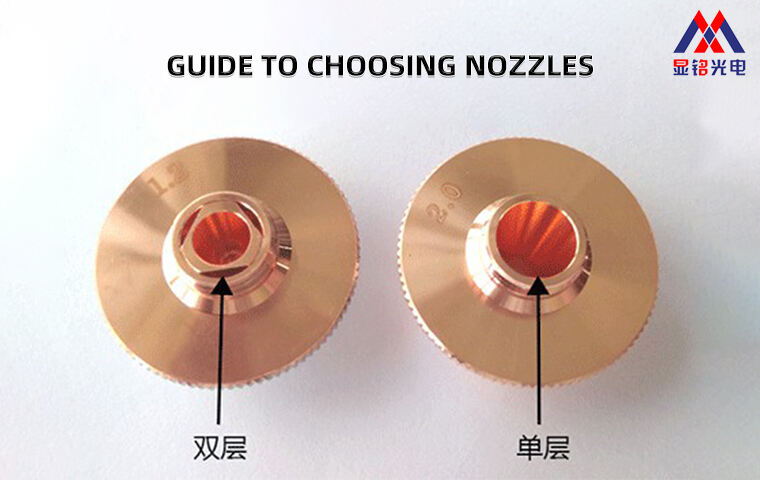

Dysze jednowarstwowe: powszechnie stosowane przy cięciu stali nierdzewnej.

Dysza wielowarstwowa: zazwyczaj stosowana do cięcia stali węglowej.

Jak wymienić dyszę

Jak wymienić dyszę

Odkręć starą dyszę;

Wkręc nową dyszę do uchwytu dyszy i dokręć;

Po wymianie wykonaj kalibrację kondensatora, aby zapewnić prawidłowe ustawienie.

Wymiana uchwytu dyszy (głowica ceramiczna)

Wymiana uchwytu dyszy (głowica ceramiczna)

Podczas cięcia mogą wystąpić kolizje, które wymagają wymiany uchwytu dyszy:

Odkręć dyszę;

Odkręć dyszę;

Ręcznie przytrzymaj głowicę ceramiczną, aby zachować jej osadzenie, a następnie usuń tuleję dociskową;

Ręcznie przytrzymaj głowicę ceramiczną, aby zachować jej osadzenie, a następnie usuń tuleję dociskową;

Wyrównaj dwa otwory pozycjonujące o średnicy 2 mm na nowej głowicy ceramicznej z pinami pozycjonującymi na uchwycie dyszy, naciśnij i obróć tuleję dociskową, aby ją zamocować;

Wyrównaj dwa otwory pozycjonujące o średnicy 2 mm na nowej głowicy ceramicznej z pinami pozycjonującymi na uchwycie dyszy, naciśnij i obróć tuleję dociskową, aby ją zamocować;

Na koniec ponownie zainstaluj dyszę.

Na koniec ponownie zainstaluj dyszę.

Mimo małych rozmiarów, dysza bezpośrednio wpływa na stabilność i precyzję cięcia. Prawidłowy dobór i terminowa wymiana dyszy nie tylko zapewnia wysoką jakość cięcia, ale również wydłuża żywotność urządzenia. Xianming Laser stale oferuje wysokowydajne urządzenia laserowe i oryginalne akcesoria, pomagając firmom w osiąganiu efektywnych, precyzyjnych i niezawodnych rozwiązań obróbki metalu.

Wybierając laser Xianming, wybierasz profesjonalizm i jakość!

Adres e-mail: [email protected]

Adres e-mail: [email protected]

WhatsApp/WeChat: +86 15314155887

WhatsApp/WeChat: +86 15314155887