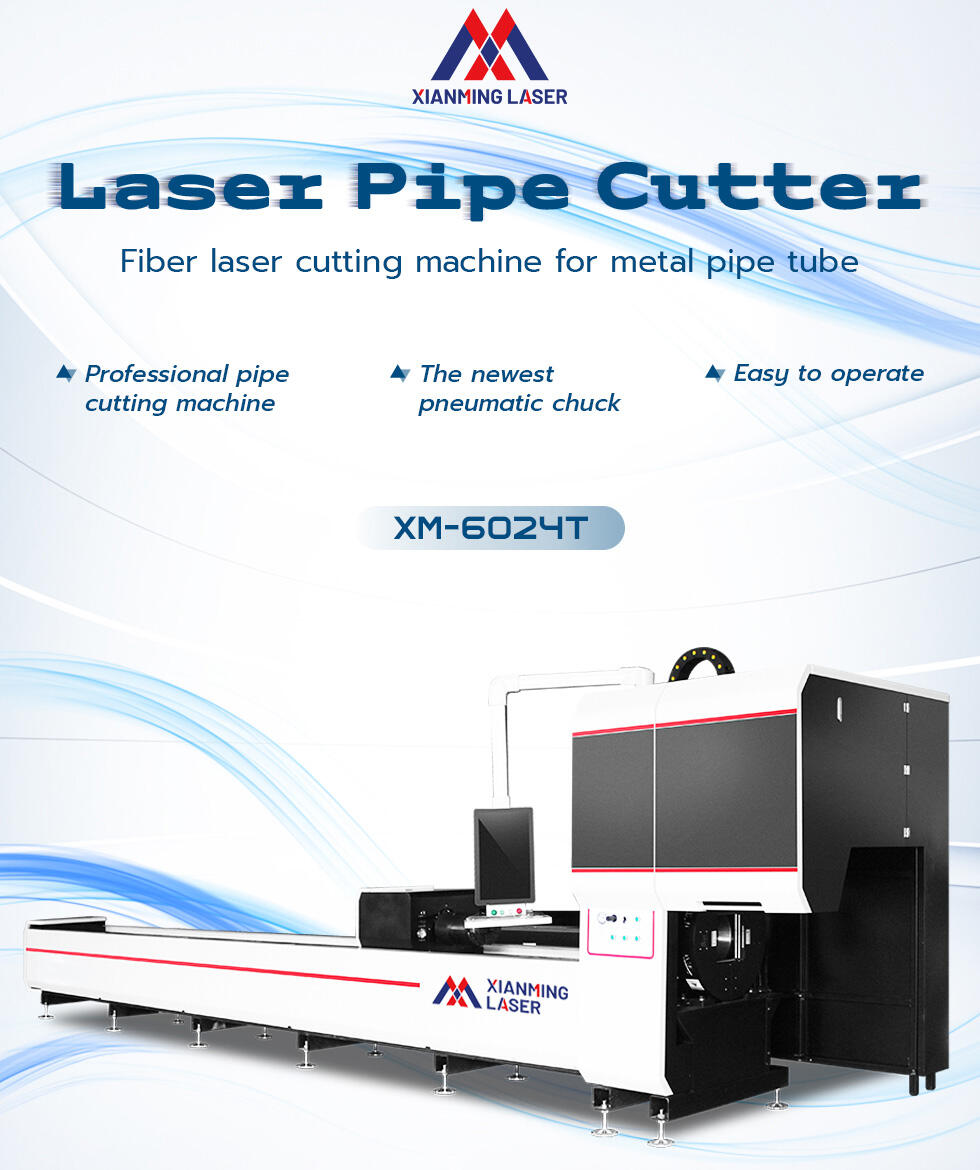

Model: XM-6024T

Working area: 6000*φ10~240mm

φ10-240mm Cutting Diameter

1500-6000W

Professional pipe cutting machine

Easy to operate

Save processing time

Improve processing efficiency

|

Minimum Order Quantity: |

1 |

|

Packaging Details: |

1.Whole film packaging Sheet fiber laser machine; 2.Anti-collision package edge; 3. Fumigation-free plywood wooden box and pallets with iron binding belt. |

|

Delivery Time: |

7-40 Days |

|

Payment Terms: |

TT (Telegraphic Transfer), Western Union, Paypa, Alibaba Trade Assurancel. |

|

Supply Ability: |

300 Set/Sets per Month |

|

Minimum Order Quantity: |

1 |

Laser tube cutting machines are advanced equipmentdesigned for the precise and efficient cutting of metal tubes and pipes. These machines utilize high-powered laser beams to achieve clean, accurate cuts with minimal material wastage. They are widely used in various industries such as automotive, aerospace, construction, and manufacturing due to their ability to handle complex cutting tasks with high precision.

01. High Precision: The laser tube cutting machine ensures precise and clean cuts, reducing the need fod post-processing it can handle intricate designs an: complex geometries with ease.

02. Efficiency: Equipped with advanced automation features, it significantly reduces production time and labon costs.The machine can cut tubes and pipes at highspeeds without compromising on quality.

03. Multifunctionality : Canable of cuttino a wide ranoe of materialel including stainless steel, carbon steel, aluminum brass. and copper Suitable for cutting various shapes such as round, square, rectangular, and oval tubes

04. Automated operation: Features like automatic loading and unloading, andntelioent nestinn sottware ontimize material usaoeand minimize wastage User-friendly interfacesdand CNC control systems make the operationstraightforward.

05. High stability and durability : Constructed with robust materials and components, ensurina lono-term durabilitv and minimali maintenance The machine's stability during operation ensures consistent cutting quality

06. Cost savings : Reduces material wastage and energy consumntion leadino to cost savinos in thel long run The multifunctional capability of cutting different tunes and shanes of tuhes and ninesl eliminates the need for multiple machines.

07.Wide Application: Ideal for cutting metal materials such as steel, aluminum, and copper, widely used in industries including mechanical manufacturing, automotive parts, and electronics.

It employs intelligent tube support design, which cansolve the deformation problems in the process of longtube cutting.

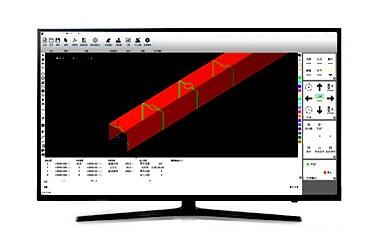

TubePro designed for professional tube cutting, sup production of tube and profile of various shap works with TubesT nesting software seamlessly to re technique setting, advanced toolpath generation nesting for standard and special productionTubePro designed for professional tube cutting, supports production of tube and profile of various shape. it works with TubesT nesting software seamlessly to realize technigue setting advanced toolpath generation and nesting for standard and special production need.

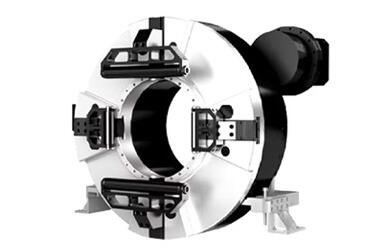

Tha eose chuele sith elsaa cs clsmn tha enacisl-chsnadlpipe keep the pipe fiting does t lipand hathe stroke is laroe the tvpe of claw is small easv to usel the clamninn forre ie etronn can realive the heauy ninel Fitting processing, and the integral support base structure, improve the support bearing stability.

Servo motors stabilise and drive the beam to control the movement of the Xy7 axis accordino to the proorammed instructions to complete the cutting operations with complex precision, and the user can adjust the parameters according to their needs.

AUTOMATIC LOADING AND UPLOADING

AUTOMATIC LOADING AND UPLOADINGThe machine is equipped with automatic loading and unloading, which can improve the utilization rate of the machine tool andimprove the work efficiency, save a lot of human resources, and meet the needs of a variety of simple material handling until the full automatic operation.

Fiber laser tube cutting machine provides exceptional versatility, capable of working with a wide range of materials including carbon steel, stainless steel, aluminum alloy, brass, copper, galvanized pipe, silicon steel tube, electrolytic pipe, titanium alloy, manganese alloy, etc.. It effortlessly handles various shapes and sizes of metal tubes, accommodating diverse project requirements.

Applicable materials: The sheet metal laser cutting machine has extensive applications in decoration, infra-structure, construction, microelectronic, advertising, kitchen appliance, automobile andother equipment manufacturing, and other industries.

|

Model |

XM-6024T |

|

Working Area |

6000*φ10~240mm |

|

Laser Power |

1500W/2000W/3000W/4000W/6000W etc. |

|

Working table |

Tube Y:6000mm X:250mm Z:200mm |

|

Cooling Method |

Water Cooling Protection |

|

Cutting Head |

Raytools/OSPR/Au3tech/WSX/Precitec |

|

Control system |

TubePro |

|

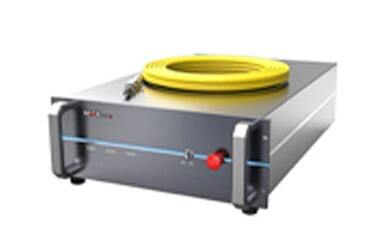

Laser source |

Max/Raycus/IPG |

|

Positioning Acccuracy |

±0.05mm |

|

Maximum Rotational Speed |

85r/min |

|

Maximum acceleration |

1G |

1. Warranty for 1 years.

2, Maintenance for whole life.

3, We will provide the consumable parts at an agency price.

4, 24 hours online service,free technical support.

5, Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6, We have manual instruction and CD/U disk for software installation,operation and machine's using and maintenance.

Q1. I knew nothing about this machine, what kind of machine i should choose?

Very easy to choose. Just tell us what you want to do by using CNC laser machine, then let us give you perfect solutions and suggestions.

Q2. What can it cut? How thick can it cut at most?

Laser machine for metal usually deal with carbon steel, stainless steel, aluminum, brass and alloy. The maximum thickness is different between different models and materials. Please check in the product introduction page.

Q3. Can I visit your factory?

Of course.Please contact us any time . We will arrange in advance.

Q4. Do you have engineer to teach me/my workers?

Yes, we offer free video training for each customer. We promise to help until everything gets right.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy policy

- Blog