Laser power: 1000W 1500W 2000W 3000W

Laser running mode: continuous clean

Machine size: 990*610*1050mm

Oxide layer removal/Grease removal/Paint removal/Rust removal

1000W water- cooled pulsed laser cleaning machine is a new type of high -power cleaning equipment. lt featuresa unique water cooling system, which can be applied to various working scenarios. The power ranges from 100W,200W, 300W, 500W, 1000w. Different control systems are available for selection. The operation is simple and it isthe best choice for users. lt is mainly used for rust removal, paint removal, glue removal, coating removal and plating removal. it is suitable for removing rust layers and thick paint layers, as well as surface roughening, weld clean.ing and other process steps. The efficiency is extremely high. lt is widely used in industries such as aviation, shipscultural relic protection, automotive accessories, food industry, railwavs, rubber molds and others.

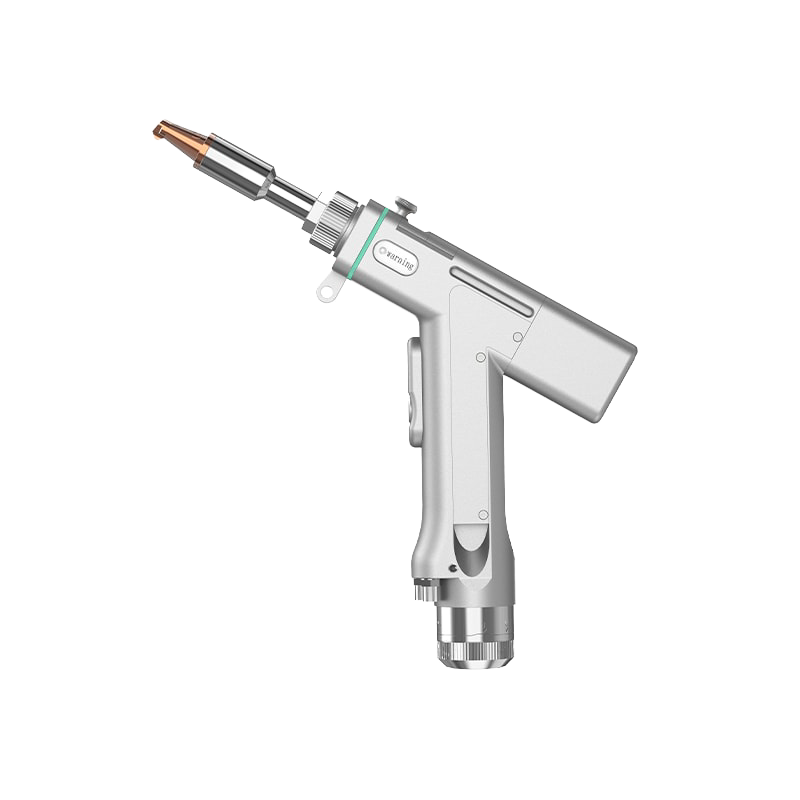

Support Relfar, Super chaoqiang, Qilin Au3Tech different brands of cleaning head.

Safety - Temperature real-time monitoring

Time saving- Easy replacement lens

Lightness -Small size, easy to use and simply to operate

Stable -Upgrade to dual protective lenses.

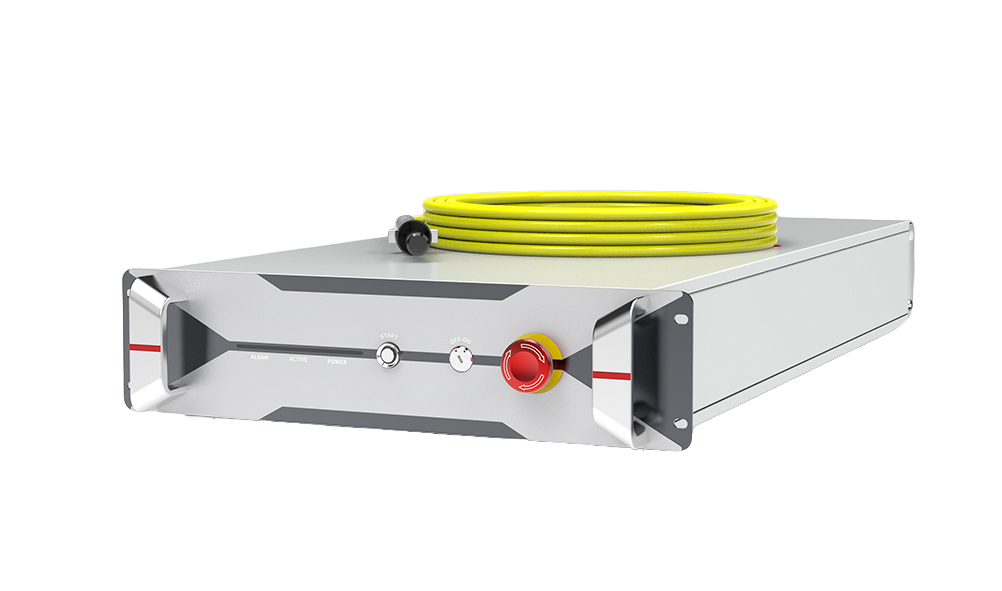

The  optional brands of fiber lasers include Raycus, RECI, GW, FEIBO, IPG, and MAX. Photoelectric conversion rate exceeds 50%, energy-saving and environmentally friendly. Working life is100, 000 hours.

The intelligent temperature controller of the laser chiller has two temperature control modes, suitable for different usage scenarios; There are multiple settings and fault display functions; The temperature control accuracy can reach ± 0.5 ℃; Stable refrigeration and easy operation;

As an advanced cleaning technology, fiber laser cleaning machine is widely used in many industries: automobile manufacturing industry, aerospace, electronic and electrical appliances, precision instruments, shipbuilding, mold manufacturing and other industries.

Whether metal, non-metal or composite materials, it can provide the right cleaning solution. For metal materials, laser cleaning can remove surface oxides, oil and coatings; For non-metallic materials such as glass, ceramics and plastics, it can remove surface stains and scratches; For composite materials, laser cleaning can ensure that the cleaning effect is consistent between different materials and avoid damage to the substrate.

| Machine Name | Pulsed laser cleaning machine |

| Laser Power | 1000W |

| Laser Source | JPT |

| Laser Source Model | 1000-50 Multimode |

| Laser Model | Flat Top Light |

| Fiber Beam Quality | <9M2 |

| Maximum Single Pulse Energy | 50MJ |

| Cleaning efficiency (paint) | 30m2/h |

| Water Chiller | Hanli/S&A |

| Laser Operation Mode | Pulse |

| Pulse Width | 30-500 NS |

| Maximum Output Power | 1000W |

| Power adjustment range (%) | 0-100% |

| Fiber Cable Lenth | 15m |

| Laser Pulse Frequency | 20-1000KHZ |

| Cleaning Model | 8 Kinds |

| Working Temperature | -5~35°C |

| Cooling Water Temperature | 28°C |

| Supply Current | >32A |

| Power Instabilit | Less than 5% |

| Operation Method | Handheld |

| Total Power | 5000W |

| Auxiliary Gas Description | Dry gas (oxygen/nitrogen) |

| Machine Size (L*W*H) | 910*430*760 mm |

| Net Weight | 109 kg |

01Non-Contact Cleaning:

Non-contact cleaning, and it will not cause any damage to the component structure.

02High Power and Fast Cleaning Spssd:

Compared with lower laser power cleaning machines,with 62.5mj and 100mj maximum pulse energy,8 cleaning modes, it can clean metal, steel, stone and other materials in a shorter period of time,which can save your time cost of cleaning work.

03Environmental Protection:

The laser cleaning rust machine can remove rust without any chemical no supplies, cleaning fluid, safety and environmental protection.

04Precise Cleaning:

Precision cleaning, the laser removal machine can achieve selective cleaning and precise location.

05Extended Automation:

Can be equipped with a Robot, implementing automated operations, which can be applied to car cleaning.

Xianming Laser Co., Ltd. is an international and intelligent laser machinery manufacturer. Our main products including fiber laser cutting machine, fiber laser welding machine, CO2 laser engraving machine, laser marking machine, cleaning machine, and other laser equipments. We have launched over 60 types of laser products, covering applications in various industries such as automotive, aerospace, medical, metalworking, and electronics.Can satisfy different production needs of customers.

All our machines obtained international certifications such as CE, Rohs,and FCC. Our products have been sold to multiple countries such as the United States, Mexico, Australia,Canada,Brazil,Switzerland and have won unanimous praise from domestic and foreign users.

We also welcome OEM and ODM orders. Whether selecting from our current models in the catalog or seeking engineering assistance for your application, you can contact our customer service center regarding your procurement requirements.

01. What is the speed of the laser cleaning machine?

Different laser types determine the cleaning speed of the cleaning machine, and the cleaning speed iswithin the range of 0.5m2/h-15m?/h.

02. Is there any damage to the cleaning material?

Depends on what type you need, the pulse type has a finer cleaning effect, and the continuous type hasa faster cleaning speed,Relative damage of material, pulse type is less than continuous type.

03. What are consumable parts?

Protective glass, etc, if you order, we will send it to you together with machine.

04. Which languages are supported? Is it easy to operate?

Support language: Chinese, English, Korean, Russian, Chinese Traditional, Japanese, German, French.ltalian, Spanish, Portuguese, Turkish, Greek, Czech Slovak, Polish, Thai, Vietnamese, Romanian, etc,with clearand simple interface page Stable Various parameters can be set by yourself

05. When I get the machine, how to operate the machine?

We have user manuals and video tutorials, and this machine is very easy to use. You will soon learn howto use it.

06. ls the laser cleaning machine safe? What are the hazards to human health?

The laser cleaning machine is generally safe when used and operated correctly following safety guide.lines. However, it is essential to adhere to our instructions for implementing electrical and laser safetymeasures.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog