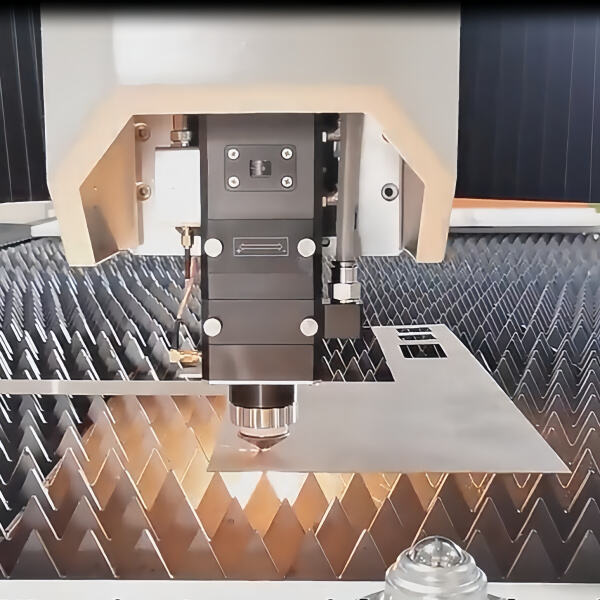

An idea of what its features are needs to be understood in order to use the 1500w fiber laser cutter. They use laser energy to cut the metal with great detail immediately. While 1500w fiber laser cutters may seem delicate on the outside, they are essential pieces of innovation for metal working.

Successfully completing your metalworking, especially in thicker gauges and lesser-known types of metals depends on knowing how to get the most out of your fiber laser cutter.

The uses are endless when it comes to the fast pace of fiber laser cutting, and someone just starting out might find that impossible at first. Thus knowing how the machine works, makes you and your safe longer during usage. Applying measures to make the cuts accurate, and in line while using tools for metal fabrication will play a great role on how these projects come out.

Adopt high level strategies Increasing your proficiency using the 1500w fiber laser cutter to be expert involves more advanced perceptual ranks. When it comes to improving cut times well you will master this one, and by varying power speed pressure of your laser beam work on pretty much any project. On the other hand, making sure that your fiber laser cutter is maintained properly through good housekeeping and replacing of consumables in time can also help prolong the life span.

Considered to be 1500w fiber laser cutter is best suited for the cutting industry because it has an outstanding accuracy and speed. With high end cutting technology it cuts through a variety of metal thicknesses with smoothness and accuracy so that every sheet is meticulously, consistently inked.

The cutting is precise and you can achieve that effortlessly by using the advanced features of a 1500w fiber laser cutter. The ability to detect edges in thick materials can save an incredible amount of time and material when users need pinpoint accuracy. Additionally, by utilizing nesting-method of laying out parts within a sheet or roll to minimize waste and reduce costs-the design could cut down on material use.

To conclude, the 1500w fiber laser cutter is redefining metal cutting across industries and ensuring state of the art manufacturing processes for better outcomes, the same as Liaocheng Xianming's fiber laser cutter. Combining the fastest speeds and most accurate cutting capabilities ever with unmatched versatility that makes it a foundation to serve all metal cut parts production requirements. Utilizing professional skills in combination with attentive machine maintenance allows for this great tool to be fully exploited.

When you move from offering professional-level cuts to producing expert-grade results with your 1500w fiber laser cutter, it calls for the utilization of advanced tactics, similar to the laser cutter cutting machine built by Liaocheng Xianming. Examples are faster cut times using piercing and improved efficiency by trimming to optimize the process. Fine-tuning the laser-cutting beam so you can adjust its power, speed and pressure to be more or less accurate lets your craftsmanship soar on all sorts of levels. Proper care and maintenance of the machine, such as cleaning its lens, workplace / work platform and timely replacement of consumables are important means to extend the service life of fiber laser cutter.

The 1500w fiber laser cutter represents the ultimate in terms of both power and precision, it is simply unrivalled within an industry that coordinates cutting technology has changed rapidly, as well as the Liaocheng Xianming's laser welding machine cost. It cuts accurately and quickly (better than competing models) while resisting any snagging of various thicknesses. This not only makes the cutting process faster, but ensures high precision in all conditions.

For us to unlock the maximum capabilities of your 1500w fiber laser cutter, You need to kick complex methods into full gear and tap more advanced features that it possesses, the same as best fiber laser cutting machine created by Liaocheng Xianming. With tasks involving thicker and pricier materials where a high degree of precision is necessary, at the expense so additional waste and manual work (on operator side), solution like edge detection can prove to be very useful. Nesting- Similarly more efficiently than other sheet design options in the way it allows you to pack elements together nicely on a single piece of material.

Available standalone, in this case the CNC fiber laser cutter 1500w version is a versatile tool that will redefine manufacturing capabilities. As a result, this adaptability to complex designs and multiple materials allows manufacturers to quickly adjust as their production needs evolve. Combining the latest in technology along with human knowledge and creativity, this Best-in-class product simplifies design-to-production process providing fast accurate results effortlessly.

In summary, the 1500w fiber laser cutter is a game-changer in metal cutting that has streamlined processes for countless manufacturers aiming to get superior results from their practices, as well as the Liaocheng Xianming's best fiber laser cutting machine. With high-speed precision and multi-function operation, this machine possesses the state-of-the-art in metal cutting versatility for a multitude of applications stage. Integrating tried and tested professional techniques with reliable cutting practice allows you to utilize the power of this special tool.

Liaocheng Xianming machines market and sales network across significantly more than 60 countries and areas, include a professional logistics procedure which supplies customers with quick transportation services making sure that logistics gets to be more convenient. If you should be a person as an ongoing company we does our far better satisfy your desires and transport your fiber laser machine to its location swiftly and safely.

Liaocheng Xianming gives a lot of attention to after-sales services, knowing that the quality of service provided by fiber-laser machines for us are equally crucial.

Liaocheng Xianming includes a 30000 square meters manufacturing facility. We has a r which was top d in the commercial, and we pay attention to the manufacture of numerous types of fiber laser machines.

Liaocheng Xianming is able to offer customers logos as well as other agents that may be customized with product images featuring the logo for the client, videos as well as other materials. The dietary fiber laser machine is preferable to other suppliers.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog