Laser Welding Cutting Machines: How A Revolotionary Product Can Make Magic

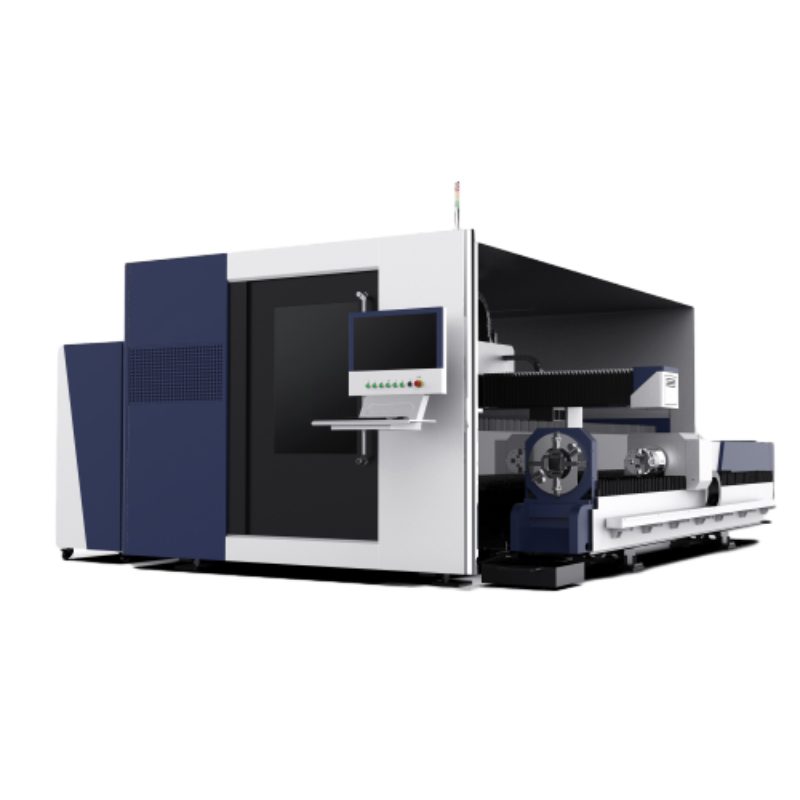

This special tool is mainly used in the factory - laser welding cutting machine. Lasersenia A laser is employed to combine or sever metal with a powerful beam of light. These lasers are extremely powerful and can accurately heat, meltand cut metal to shape. This greatly benefit the laser welding cutting machine in many factory work.

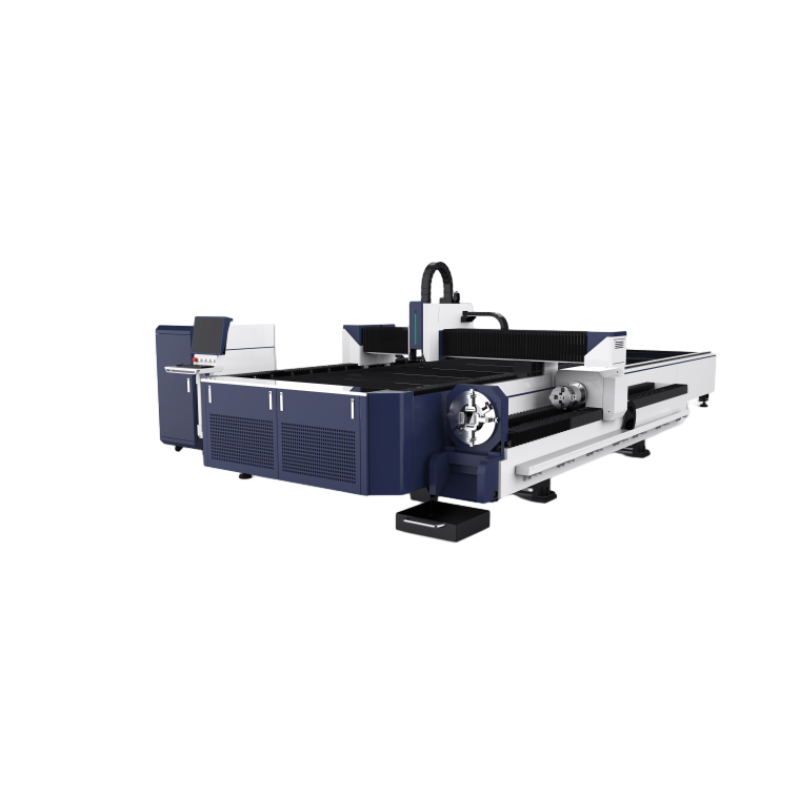

Now, do you know one of the coolest things about laser welding cutting machines? Complex Cuts and Welds on MetalWhile it can be used for KISS purposes, the necessary output of a laser cutter is totally unforgiving; on one hand you get meticulous cuts that are complicated (ideal for creating ornate design or making small metal parts just so)ultimate detail!

These machines also work in split second. Many metal parts can be produced in a short time, so they are fast and effective. That helps factories produce more stuff, in less time and at a lower cost.

Laser welding cutting machines have revolutionized factories. They are making it quicker and more efficient to produce metal parts than ever before. So factories can create more things and spend less money on doing so.

They also facilitate the more robust metal parts manufacturing. They are able to produce more identical pieces that have less fault to it compared with from heritage approaches. Which indicates that companies can create goods more solid which do the job well, and consequently inevitably are set to survive longer.

How important are Laser Welding Cutting Machines to factories.

Today, in factories laser welding cutting machines play a very important role. They are used to produce various metal parts for automotive and aerospace applications. These facilities can't create these industries' metal components in an helpful way without the need of them, and we really would not have lots on the items that individuals use every single day.

Ways in Which Laser Welding Cutting Machines Are Revolutionizing Design and Production

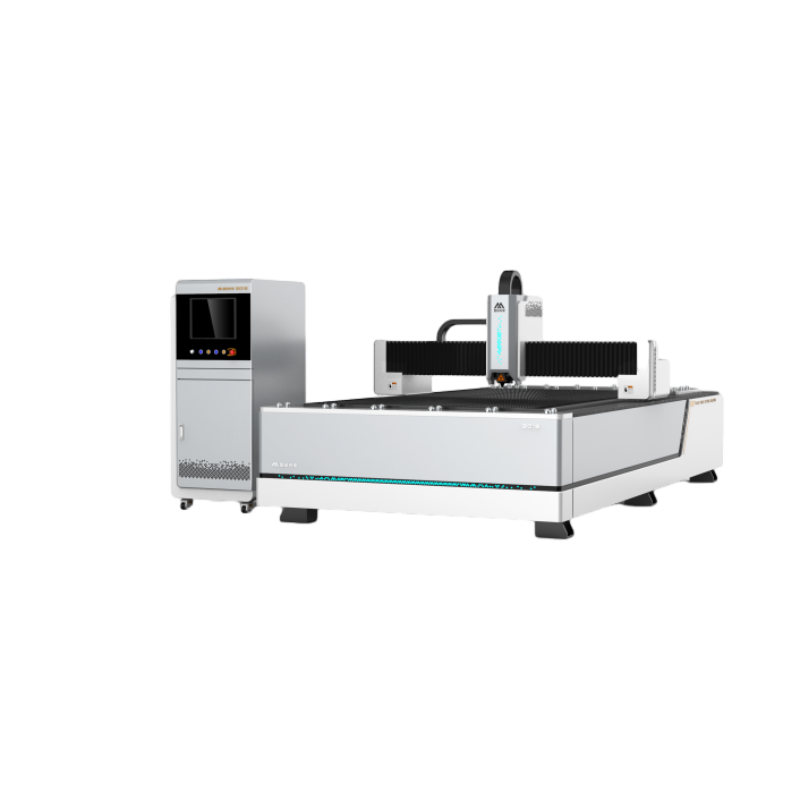

Laser welding cutting machines are poised to revolutionize the way we make things. I am able to create far more complex parts than I ever could have with the methods of old. This allows designers and engineers to make new products that could not be made before. They can manufacture car parts that are lighter, stronger and kinder to the environment.

In summary, laser welding cutting machines are incredible tools that have made a huge impact on how we manufacture stuff. They better the manufactures and help us build a future that works well and is eco-friendly.

So let us discover some more about the wonderful realm of laser welding cutting machines. In manufacturing environments, these nifty devices are a key tool in many industries. These machines use the power of lasers, and they are capable both in joining as well as cutting metal materials with extreme accuracy. Laser welding cutting machines have completely revolutionized the way industrial applications were being carried out.

Another clear benefit laser welding cutting machines provide is the superb accuracy. The intricate and accurate designs they make for the very effectively are truly incredible. Furthermore, they also work at incredibly fast speeds and can be utilized to produce a large number of metal components relatively quickly. This fast rate improves production and lowers factory costs.

Add Commentcnc laser cutting machine,Laser Welding Cutting MachinesSeptember 2022August 2019July

Laser welding cutting machine has changed the way manufacturing and fabrication facilities work. These modern-day machines set new benchmarks for accuracy and speed in the field of manufacturing metal parts. As a result, factories have enjoyed higher levels of productivity and lower operational costs. Besides, the premium nature of metal components produced with laser welding cutting machines only further reaffirms their crucial role in maintaining strength and longevity within final products.

How Laser Welding Cutting Machines Are Vital for Our Factories Today

Laser welding cutting machines are resources with an important place among the complex pattern of present day industrial facilities. One cannot stress enough their job in the production of an extensive scope of metal parts for different ventures, automotive and aerospace businesses for example. These machines, which are critical to leveraging everyday products consuming high-quality metal components at scale would not be produced in a seamless way without them.

Laser Welding Cutting Machines have Changed the Face of Design and Production

However, the influence of laser welding cutting machines is far more than just manufacturing process. Laser power and beam quality reshape the precedent that designers always have in mind when they carry out imagination without limits during production designing: "Is it possible to manufacture?" These advanced machines allow designers and engineers to create complex, innovative product designs that were previously impossible. One example is the use of laser welding cutting machines to make auto body parts that are lighter, stronger and more environmentally friendly - which can contribute to sustainable manufacturing.

Ultimately, these laser welding cutting machines represent the zenith of technological excellence that is pushing industries towards a future marked by efficiency, dependability and conservational friendliness.

Liaocheng Xianming machines market and sales network across significantly more than 60 countries and areas, include a professional logistics procedure which supplies customers with quick transportation services making sure that logistics gets to be more convenient. If you should be a person as an ongoing company we does our far better satisfy your desires and transport your fiber laser machine to its location swiftly and safely.

Liaocheng Xianming gives a lot of attention to after-sales services, knowing that good service fiber laser machines for us is equally crucial. We stick to the principles that are line with customer-centric and global presence. This is made possible by support for the service network.

Liaocheng Xianming gives customers with customized logos and images, videos along with other materials. Agents are often in a position to provide branded merchandise by customers. The fiber Laser machine is way better to many other providers.

Liaocheng Xianming has a 30000sqm manufacturing unit. We want the top r D department in the industry, therefore we look at the creation of various kinds of fiber lasers.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog