Diving into The World of Sheet Metal Fabrication Using Laser Cutting Machines

Sheet metal manufacturing is a process that has been used in advanced marketing for a long time. You would need a sheet laser cutting machine to make sure you have the exact shapes and sizes. These types of machines are critical in order that companies can perform functions with greater precision so they take part on the production. Here is one more moment to know the top 5 young lady laser shaper from its speculation, exceptional viewpoints and advantages for what's to come in sheet metal creation.

5 Best Sheet Laser Cutting Machines For High Precision Cuts - A Detailed Analysis

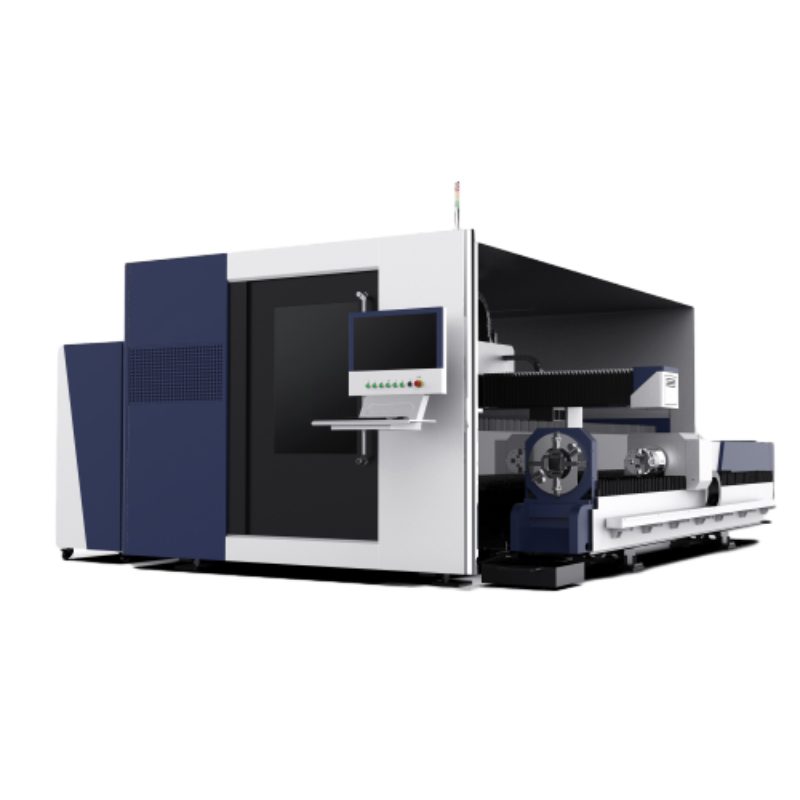

Bystronic BySprint 3015 Fiber Laser Cutting Machine

With these you can cut up to 3m,

Allows a cutting speed up to 30 meter per minute

With stable laser and automatic control to ensure exact cutting.

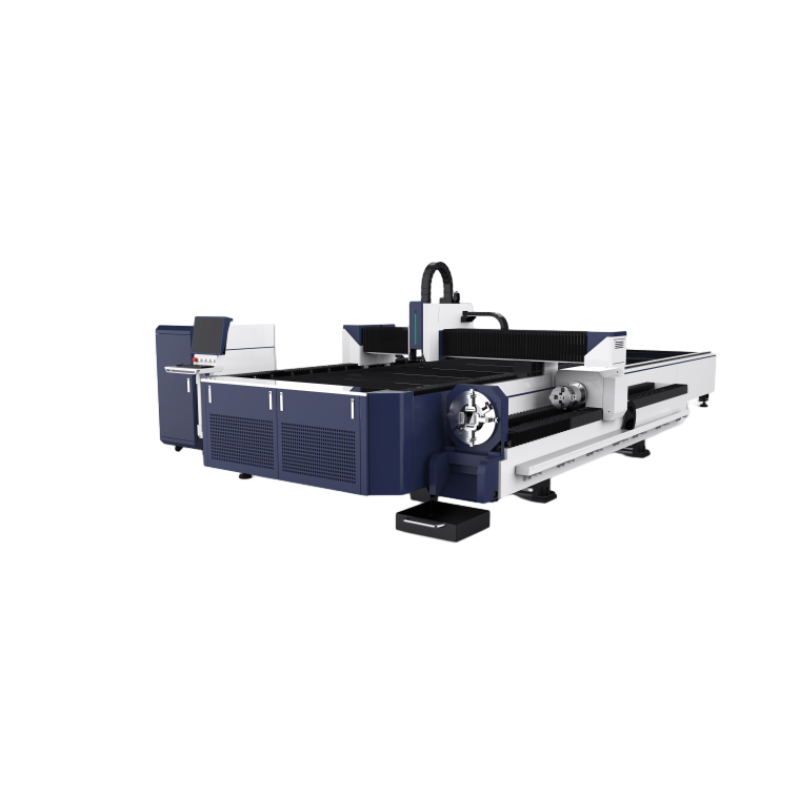

The Amada Ensis-3015AJ Fiber Laser Cutting Machine

Cuts even the thickest sheet in seconds

Rapid loading and unloading system to keep production working continuously

Great for businesses that need to cut a lot of material

Auto focus & automatic nozzle changer airtight smooth operation

Well known for its outstanding accuracy and reliability

They can cut with fast cutting speeds that are used for a variety of applications

Sella Mazak Optiplex Fiber Laser Cutting Machine

Known for it's versitility and ability to cut very thin sheets without warping

Seamlessly fits into a complete production line installation

Prima Power Platino Fiber Laser Cutting Machine [Video]

Delivers a cut capacity of 4 metres

For Companies With High Volume of Cutting Requirements

Comes with automatic loading and unloading functionalities for fully uninterrupted production

High quality, low maintenance cuts with laser cutting technology

A detailed introduction to the features and benefits of sheet laser cutting machine

One of the biggest advantages for sheet metal fabrication businesses is the use of a Sheet Laser Cutting Machine. Apart from delivering accurate cuts, these machines help in increasing the work speed thereby leading to better productivity and lesser wastage of materials. In this article, we are going to talk about some main functions and benefits of the sheet laser cutting machine:1.

Sheet laser cutting machines make accurate cuts reducing the need for secondary finishing processes thereby saving time and costs.

Higher Productivity: With their incredibly fast cutting speeds combined with automation, sheet laser cutting machines can help you exponentially increase your productivity and output.

Material Waste Reduction: Because sheet laser cutting machines allow for very precise cuts, wastage of material is kept to a minimum; saving cost whilst providing an even more sustainable process.

Low Maintenance Demands - Sheet laser cutting machines also require only a minimal amount of maintenance, which in turn prevents downtime and increases the longevity of these high-tech systems.

Sheet Laser Cutting Machines for Small Scale Enterprises

Although you might come across the sheet laser cutting machines which are just too much expensive like hundreds of thousands to a million-dollar, there is still another type that helps businesses in small scales. Some popular options include:

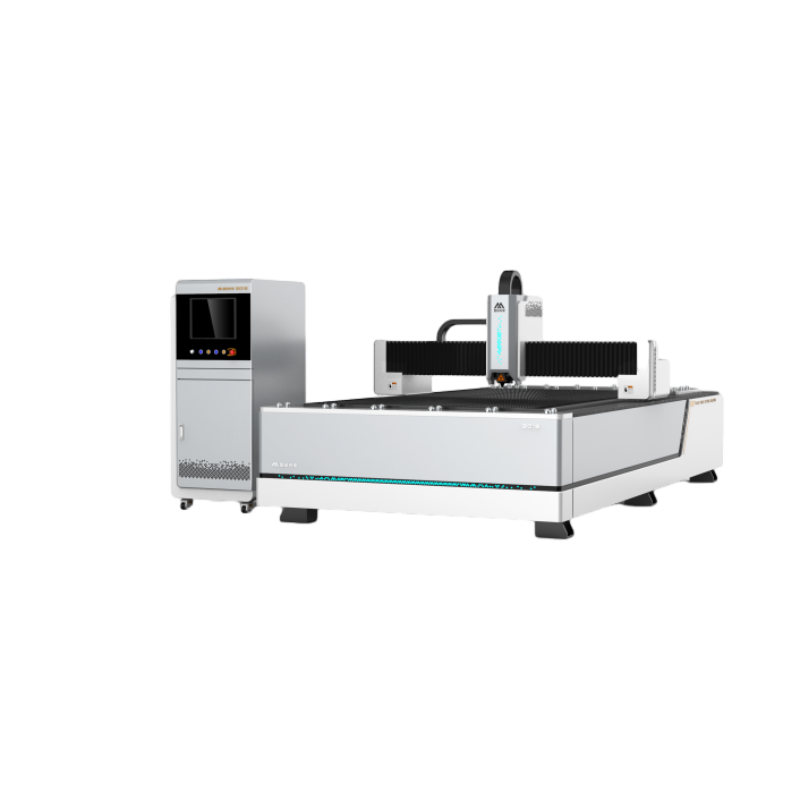

Bodor Metal Laser Cutting Machine: The device is a compact entry-level sheet metal fabrication unit with an easy design and user-friendly software. Plethora Of Features Available For A Rock Til The Cows Come Home Price - This thing is super affordable and cuts impressively cleanly with decent regularity.

Full Spectrum Laser CO2 Laser Cutting Machine: Traditionally these machines are small and cheap enough for small businesses who just want a simple, user-friendly way to cut sheet metal. A powerful CO2 laser and smart software make it easy to use.

How Laser Cutting Machines Turn Sheet Metal Fabrication Into the Future

Laser cutting machines have ramped up metal fabrication with all its modern possibilities, so they are transforming sheet metal fabrication in ways you might not even expect. For the future, we are expecting more high tech laser cutting technologies which will increase accuracy and efficiency. Some specific sectors of growth include:

Automation Enhancements: Expect advanced automation capabilities to be added which will allow the laser cutting machine run autonomously with lesser dependence on human inputs.

Better Integration: These laser cutting machines will be easily integrated into larger industrial line, whereby the company can enjoy higher effectiveness as well as efficiency.

Exploration of Advanced Materials: Laser cutting machines will show us advanced designs in lesser time and ability to handle a broad spectrum like exotic metals, composites which can lead businesses to produce more intricate uncommon design requirement focusing on rarity.

Schemes for Improving Operational Efficiency & Productivity

Business Optimization Strategy in the Sheet Metal Fabrication Industry

Invest on Equipment:Choose a sheet laser cutting machine according to the specific requirements of your company for optimum efficiency and productivity.

Increase Automation: Implementing automation in your manufacturing processes can drastically reduce downtime, do away with redundancies and boost productivity overall.

This includes Employee Training: Properly training your workers may benefit you in improving the operational quality and capacity to use a laser cutting machine, reducing errors or downtime.

To sum up, sheet laser cutting machines are crucialequipment for the entire market of manual processing.Businesses reallyneed this sort of equipment. The machines offer great precision while providing high-quality goods and reduce material wastage significantly making them a significant resource for many industries increasing efficiency, productivity among-st other benefits of using the machine. Businesses can set themselves up for long term success by making reach machine choices, automating the process where possible and offering training to their workforce.

Liaocheng Xianming includes a 30000 square meters manufacturing facility. We has a r which was top d in the commercial, and we pay attention to the manufacture of numerous types of fiber laser machines.

Liaocheng Xianming Machines a professional logistic packaging to deliver quick and efficient transportation services to customers which make logistics more cost-effective. We'll do our most readily useful to make sure the fiber laser machine also includes its destination quickly and properly, regardless of irrespective of whether you're an individual as business.

Liaocheng Xianming gives customers with personalized logos and videos, graphics plus materials. Agents could also provide customer-branded products. The fiber Laser machine are a lot better than other manufacturers.

Liaocheng Xianming gives a lot of attention to after-sales services, knowing that good service fiber laser machines for us is equally crucial. We stick to the principles that are line with customer-centric and global presence. This is made possible by support for the service network.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog