Christmas Greetings from Xianming Laser | Professional Fiber Laser Machine Manufacturer

As temperatures continue to drop, low-temperature environments place higher demands on the stable operation of laser equipment. If the cooling system is not properly protected, the cooling water inside the laser source or laser tube may freeze and expand, leading to frozen or ruptured internal pipelines—and even irreversible damage.

To effectively avoid risks caused by winter low temperatures, Xianming Laser kindly reminds you to take anti-freeze precautions in advance.

Replace the Cooling Medium in Time to Prevent Freezing Damage

Replace the Cooling Medium in Time to Prevent Freezing Damage

In low-temperature environments, be sure to replace the deionized water or purified water in the water chiller with a suitable antifreeze to prevent the cooling system from freezing.

Important Notice:

Failures or damages caused by the absence of anti-freeze measures or improper use of antifreeze are not covered by the equipment warranty.

Proper Water Temperature Settings for Chillers (Fiber Laser Cutting Machines)

Proper Water Temperature Settings for Chillers (Fiber Laser Cutting Machines)

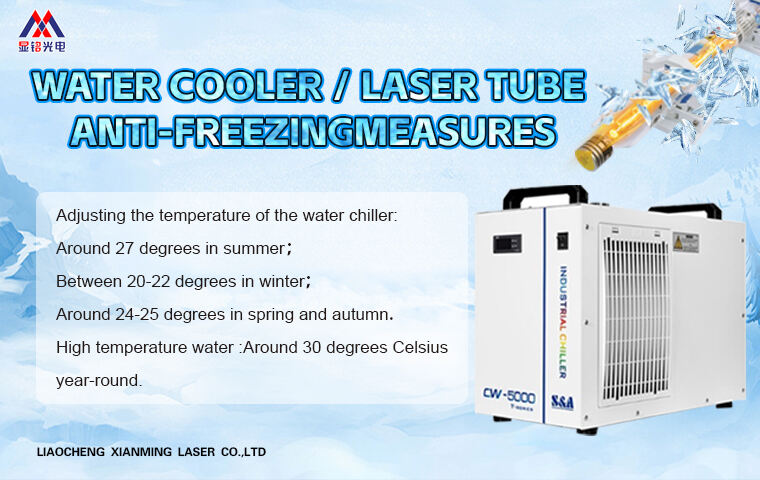

According to seasonal ambient temperatures, we recommend adjusting the chiller water temperature as follows:

Low-temperature water setting recommendations:

Summer: approx. 27°C

Winter: 20–22°C

Spring / Autumn: 24–25°C

High-temperature water setting recommendation:

All-year ambient temperature: approx. 30°C

Reasonable water temperature settings not only help prevent freezing but also improve the overall operational stability of the laser equipment.

Antifreeze Selection Recommendations (Suggested Brand)

Antifreeze Selection Recommendations (Suggested Brand)

Xianming Laser recommends Clariant antifreeze products, which are suitable for laser system cooling. The main types include:

Ethylene glycol–water antifreeze with antibacterial additives

Industrial-grade product; toxic to humans—proper protective measures are required during use.

Propylene glycol–water antifreeze (anti-allergy type)

Food-grade; non-toxic to humans, safer and more environmentally friendly.

Important Precautions (Must Be Observed)

Important Precautions (Must Be Observed)

Do not use alcohol or other corrosive antifreeze agents

Any equipment damage caused by the use of non-compliant antifreeze must be borne by the customer

Antifreeze cannot fully replace deionized water

Antifreeze is not recommended for year-round, long-term use

Necessary Maintenance Steps After Winter

Necessary Maintenance Steps After Winter

After the cold season ends, please be sure to perform the following steps:

Thoroughly flush the cooling pipelines with deionized or purified water

Discontinue the use of antifreeze

Resume using deionized or purified water as the cooling medium

This step is essential to ensure the long-term stable operation of the laser source.

Conclusion

Proper winter anti-freeze protection is a critical part of ensuring the safety, stability, and efficiency of laser equipment. Xianming Laser remains committed to safeguarding your laser equipment throughout its entire lifecycle. If you have any questions regarding antifreeze selection or cooling system maintenance, please feel free to contact us at any time.

Xianming Laser — Protecting Every Machine with Professional Care.