Essential Water Circuit and Lubrication Guidelines for Fiber Laser Cutting Machines

In the operation of a fiber laser cutting machine, the correct configuration and maintenance of the liquid systems are crucial for ensuring equipment stability and cutting precision. These requirements mainly include two parts: the water circuit connection and the guide rail lubrication.

Water Circuit Connection

Water Circuit Connection

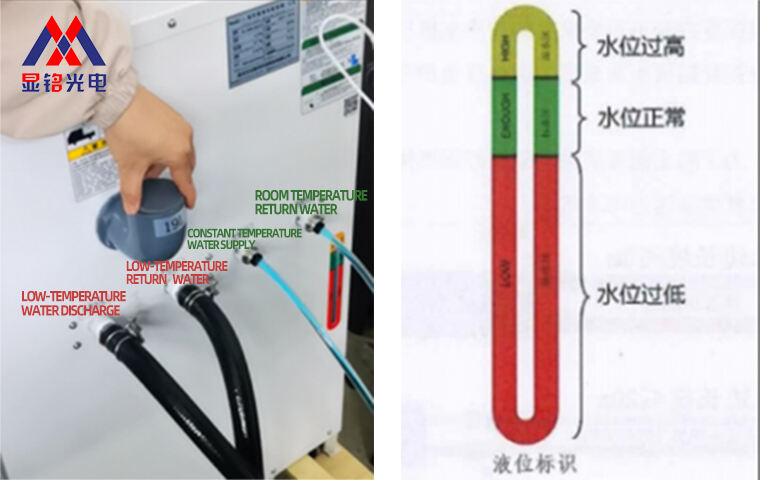

The cooling system of a fiber laser cutting machine relies on a chiller for circulating cooling water. The correct connection between the machine and the chiller is as follows:

The machine’s normal-temperature outlet should be connected to the chiller’s normal-temperature outlet.

The machine’s normal-temperature outlet should be connected to the chiller’s normal-temperature outlet.

The machine’s normal-temperature return port should be connected to the chiller’s normal-temperature return port.

The machine’s normal-temperature return port should be connected to the chiller’s normal-temperature return port.

The machine’s low-temperature outlet should be connected to the chiller’s low-temperature outlet.

The machine’s low-temperature outlet should be connected to the chiller’s low-temperature outlet.

The machine’s low-temperature return port should be connected to the chiller’s low-temperature return port.

The machine’s low-temperature return port should be connected to the chiller’s low-temperature return port.

When adding water, fill the chiller through its designated water inlet using pure water or distilled water, ensuring that the water level reaches the standard zone (green area).

Do not use tap water or mineral water, as impurities and scale buildup can block the cooling pipes or cause poor heat dissipation in the laser source.

Guide Rail Lubrication

Guide Rail Lubrication

To ensure smooth operation of the moving parts and extend the machine’s lifespan, it is essential to regularly apply appropriate guide rail lubrication oil.

As shown in the diagram, add oil through the designated oil ports, ensuring a proper amount—neither too much nor too little.

Proper use and maintenance of liquids not only enhance the performance of the laser cutter machine but also significantly reduce failure rates and extend the overall service life of the equipment.

Email: [email protected]

Email: [email protected]

WhatsApp/WeChat: +86 15314155887

WhatsApp/WeChat: +86 15314155887