Fiber Laser Cutting Machine Focus Adjustment Guide | How to Adjust the Focus Position for Optimal Cutting Results

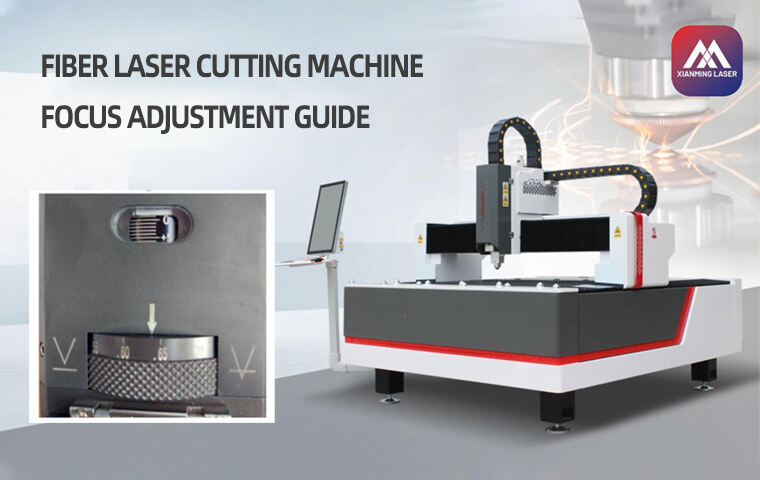

In fiber laser cutting, accurate focus adjustment plays a decisive role in achieving high-quality cuts, smooth edges, and stable performance. The manual focusing laser head of the Xianming Laser fiber laser cutting machine is equipped with a rotary focusing scale ring, allowing precise movement of the focal point to optimize cutting performance for different materials and thicknesses.

Focus Adjustment Structure

Focus Adjustment Structure

The focusing lens inside the laser head features a 20mm back-and-forth travel range, enabling fine adjustment of the focus position. Before cutting, it is essential to confirm the correct focal point.

At the factory, the "zero focus" position is already calibrated — both the window "0" mark and the rotary ring "0" scale align, indicating the laser focus is at the nozzle surface.

⚙️ Note: If you need to readjust the "zero focus", please contact your Xianming Laser customer manager or email us at [email protected] for assistance.

Scale Reading and Focus Position Relationship

Scale Reading and Focus Position Relationship

The focus adjustment range of the fiber laser cutting head is "+8 to -12." The scale value directly indicates the laser focus position:

Scale 0: The focal point is at the nozzle surface.

Scale +8: The focal point is 8mm inside the nozzle.

Scale -12: The focal point is 12mm below the nozzle.

Fine-tuning this position helps optimize cutting efficiency, edge smoothness, and gas flow performance.

Focus Type, Cutting Material, and Section Characteristics

Focus Type, Cutting Material, and Section Characteristics

| Focus Type | Focus Position | Applicable Material | Section Features | Cutting Characteristics |

| Zero Focus | Laser focus on the upper surface of the sheet | General sheet metal | Smooth upper and lower surfaces | Ideal for thin and medium plates |

| Positive Focus | Focus above the upper surface of the sheet | Carbon steel plate | Smooth top surface, rougher bottom surface | Wider kerf, higher gas flow, longer piercing time |

| Negative Focus | Laser focus is located below the lower surface of the metal plate | Stainless steel, copper, aluminum plate | The upper cutting seam is narrow, while the lower seam is wider | Suitable for nitrogen-assisted cutting; better protects the molten area and improves cutting stability |

Recommended Focus Settings for Fiber Laser Cutting Machines

Recommended Focus Settings for Fiber Laser Cutting Machines

For carbon steel laser cutting, use positive focus to enhance upper surface quality and reduce spatter.

For stainless steel laser cutting or aluminum laser cutting, use negative focus to achieve clean edges and prevent burrs.

For thin metal sheet cutting, maintain zero focus for balanced cutting performance.

Proper focus adjustment can significantly improve laser cutting precision, reduce slag, and increase cutting speed, ensuring that your fiber laser cutting machine operates with maximum efficiency and accuracy.

Xianming Laser — Professional Fiber Laser Cutting Machine Manufacturer

Enhancing productivity and precision with advanced fiber laser cutting technology.

Email: [email protected]

Email: [email protected]

WhatsApp/WeChat: +86 15314155887

WhatsApp/WeChat: +86 15314155887