Fiber Laser Cutting Machine: Gas Connections and Usage Guidelines

In the operation of fiber laser cutting machines, the correct selection of auxiliary gases and proper gas line connections are crucial to ensure cutting quality and equipment stability. Below is a detailed guide on gas specifications, connection methods, and safety precautions.

Auxiliary Gas Specifications and Requirements

Auxiliary Gas Specifications and Requirements

Oxygen (O₂)

Oxygen (O₂)

Purity Requirement: ≥ 99.95%

Application: Used for cutting carbon steel and other ferrous materials. It improves cutting speed and enhances edge quality.

Notes: Oxygen must be free of moisture, oil, or any impurities to avoid cutting defects and ensure equipment safety.

Nitrogen (N₂)

Nitrogen (N₂)

Purity Requirement: ≥ 99.95%

Application: Suitable for stainless steel, galvanized sheet, and similar materials. It prevents edge oxidation and maintains a bright, clean cutting surface.

Compressed Air

Compressed Air

Purity Requirement: Clean, dry, oil-free, and impurity-free.

Application: Often used for thin carbon steel and thin stainless steel cutting. It is cost-effective and suitable for medium to low-thickness metal processing.

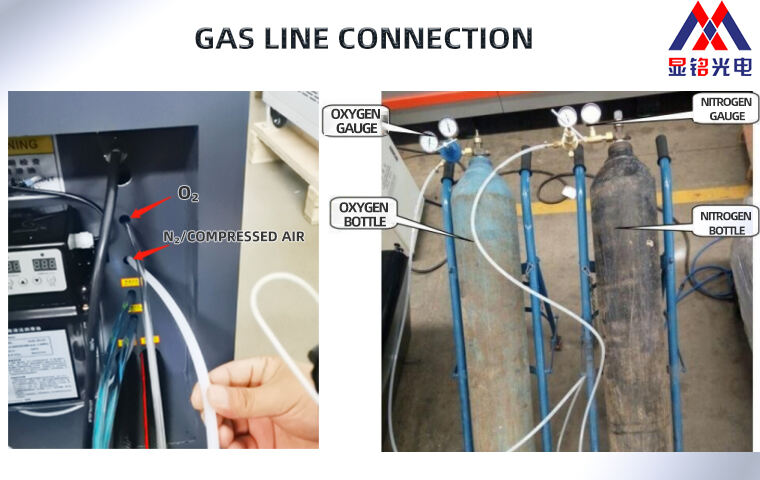

Gas Connection Methods

Gas Connection Methods

Oxygen Connection

Oxygen Connection

Connect the oxygen pipe at the rear of the machine to the regulator on the oxygen cylinder.

Adjust the output pressure of the regulator to around 0.5 MPa to ensure stable gas supply during cutting.

Nitrogen / Air Connection

Nitrogen / Air Connection

Connect the nitrogen/air pipe at the rear of the machine to the nitrogen regulator or air compressor.

Set the output pressure to above 1.6 MPa to meet the required flow rate and cutting pressure.

Safety Precautions

Safety Precautions

Auxiliary gases must meet the specified purity requirements; otherwise, cutting quality may decrease, and optical components may be damaged.

Auxiliary gases must meet the specified purity requirements; otherwise, cutting quality may decrease, and optical components may be damaged.

Regularly check gas line connections to avoid leaks or loosening.

Regularly check gas line connections to avoid leaks or loosening.

Compressed air must be dried and filtered to prevent moisture and oil from entering the system.

Compressed air must be dried and filtered to prevent moisture and oil from entering the system.

Proper gas selection and secure connections are the foundation for high-quality laser cutting. By following these guidelines, you can ensure stable machine operation, extend equipment lifespan, and achieve optimal cutting results.

Follow Xianming Laser to learn more!

Email: [email protected]

Email: [email protected]

WhatsApp/WeChat: +86 15314155887

WhatsApp/WeChat: +86 15314155887