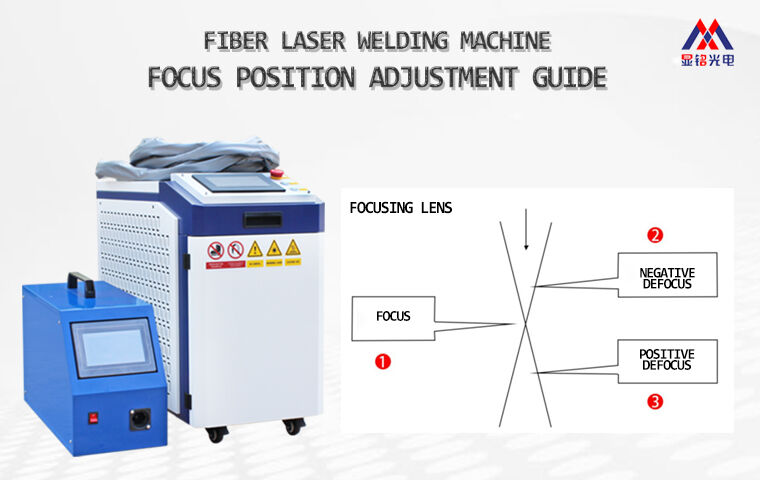

Fiber Laser Welding Machine Focus Position Adjustment Guide

In laser welding applications, focus position adjustment plays a critical role in determining weld penetration, spot size, energy density, and overall weld quality.A correct focal setting can significantly reduce spatter, prevent burn-through, and ensure stable, consistent weld seams.

As a professional laser equipment manufacturer, Xianming Laser welding machines provide precise focus control and stable energy output, allowing users to easily switch between spot welding, deep penetration welding, and surface sealing processes.

Focus Position (Zero Focus)

Focus Position (Zero Focus)

Key Features

Smallest spot diameter

Smallest spot diameter

Highest energy density

Highest energy density

Most concentrated laser power

Most concentrated laser power

Strongest spark and crispest sound

Strongest spark and crispest sound

Best Applications

Precision spot welding

Precision spot welding

Small weld points

Small weld points

Low-energy fine welding

Low-energy fine welding

Thin materials

Thin materials

At the exact focal point, the laser energy is highly concentrated, producing fast melting and minimal weld size.

This setting is ideal for micro welding tasks where high precision and a small heat-affected zone are required.

Negative Defocus Position (Focus Below the Surface)

Negative Defocus Position (Focus Below the Surface)

Key Features

Slightly larger spot

Slightly larger spot

Energy penetrates deeper into material

Energy penetrates deeper into material

Greater penetration depth

Greater penetration depth

Strong keyhole welding effect

Strong keyhole welding effect

Best Applications

Deep penetration welding

Deep penetration welding

Continuous seam welding

Continuous seam welding

Thick plate welding

Thick plate welding

Structural joints

Structural joints

Negative defocus allows the laser to deliver more energy into the interior of the material, creating stable deep weld pools.

This is the most commonly used setup for heavy-duty industrial welding where strength and penetration are critical.

Positive Defocus Position (Focus Above the Surface)

Positive Defocus Position (Focus Above the Surface)

Key Features

Larger spot size

Larger spot size

Lower energy density

Lower energy density

Shallower penetration

Shallower penetration

Smoother and more stable weld surface

Smoother and more stable weld surface

Best Applications

Surface sealing welds

Surface sealing welds

Cosmetic welds

Cosmetic welds

Thin sheet welding

Thin sheet welding

Low penetration requirements

Low penetration requirements

Positive defocus spreads the energy more evenly, which helps prevent overheating or burn-through.

It is particularly suitable for thin materials or applications requiring a clean surface finish.

Practical Tips for Continuous Penetration Welding

Practical Tips for Continuous Penetration Welding

During actual production, you can quickly evaluate whether the focus is correct by observing the backside of the workpiece:

Reference Guide

Slight discoloration → Proper penetration

Slight discoloration → Proper penetration

Visible melting mark → Energy slightly high

Visible melting mark → Energy slightly high

Full burn-through or holes → Excessive power

Full burn-through or holes → Excessive power

Heavy spatter or deep pits → Over-penetration

Heavy spatter or deep pits → Over-penetration

If welding defects occur, adjust:

Focus distance, Laser power, Waveform parameters,Welding speed.

Always test samples before mass production to achieve optimal results.

Focus Selection by Material Thickness

Focus Selection by Material Thickness

| Material Thickness | Recommended Spot | Suggested Mode |

| Thin sheet | Small spot | Focus or positive defocus |

| Medium plate | Medium spot | Slight negative defocus |

| Thick plate | Larger spot + deep weld | Negative defocus |

Thinner materials require smaller spots, otherwise burn-through may occur easily.

Why Choose Xianming Laser Welding Machines?

Why Choose Xianming Laser Welding Machines?

Xianming Laser systems are designed for flexible and precise laser welding control, featuring:

Accurate focus adjustment structure

Accurate focus adjustment structure

Stable laser energy output

Stable laser energy output

Programmable waveform control

Programmable waveform control

Compatible with spot, seam, and deep penetration welding

Compatible with spot, seam, and deep penetration welding

Suitable for stainless steel, carbon steel, aluminum, and other metals

Suitable for stainless steel, carbon steel, aluminum, and other metals

These advantages help customers achieve:

✔ Deeper penetration

✔ Less spatter

✔ Cleaner weld seams

✔ Higher efficiency

✔ More stable production

Conclusion

Understanding laser focus position is the key to achieving better welding performance.

By selecting the correct focus, positive defocus, or negative defocus, you can greatly improve weld strength, surface quality, and overall efficiency.

With reliable laser equipment and precise control, Xianming handheld Laser welding machines help manufacturers achieve professional, high-quality results in every weld.

For more welding tips or machine solutions, feel free to contact Xianming Laser.