Why Handheld Laser Welding is Becoming the Future of Sheet Metal Fabrication

In the fast-paced world of sheet metal fabrication, staying ahead of the competition is crucial. As industries demand faster, more precise, and cost-effective solutions, traditional welding methods are being rapidly replaced by cutting-edge technologies. Among these, handheld laser welding machines have emerged as a game-changer, offering unmatched precision, speed, and flexibility. At Xianming Laser, we are at the forefront of this innovation, delivering top-tier handheld laser welding machines that are transforming the future of sheet metal fabrication.

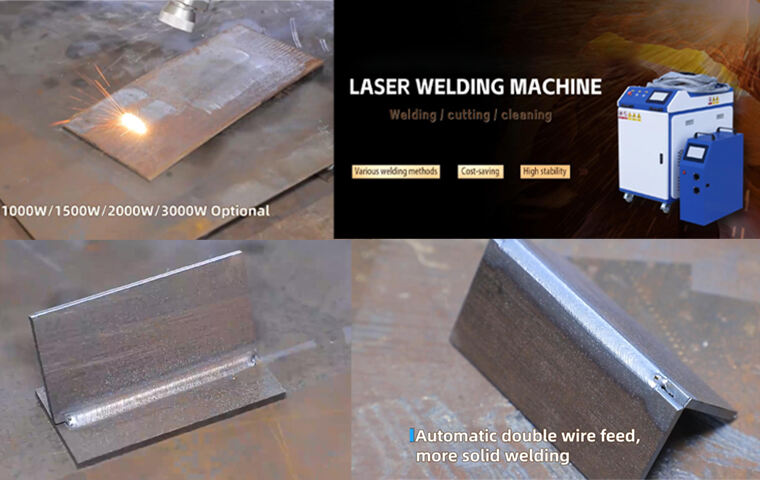

What is Handheld Laser Welding?

Handheld laser welding is an advanced technique where a laser beam is used to fuse metals together. Unlike traditional welding, which can be time-consuming and labor-intensive, laser welding offers a faster, cleaner, and more efficient solution. The handheld feature allows operators to work with greater freedom and flexibility, especially in hard-to-reach areas or complex designs, without compromising on quality or strength.

Key Features of Handheld Laser Welding Machines

-

Superior Precision and Quality

Handheld laser welding machines are capable of producing highly precise welds with minimal heat distortion. This level of accuracy is crucial when working with delicate or thin metals, ensuring the integrity and strength of the final product. -

Fast and Efficient

Laser welding is significantly faster than traditional welding methods. It requires less post-processing, which translates into lower labor costs and shorter production times. The speed and efficiency make it ideal for high-volume manufacturing environments. -

Minimal Heat Affected Zone (HAZ)

The focused laser beam generates very little heat, which means the heat-affected zone (HAZ) is minimized. This reduces the risk of warping and discoloration, ensuring that the sheet metal remains in its original form. -

Versatile and Flexible

Handheld laser welding machines can be used in a wide range of applications, from thin sheet metals to more complex assemblies. Whether you are working with stainless steel, aluminum, or other metals, these machines offer the versatility needed for various fabrication tasks. -

Easy to Operate

Unlike bulky traditional welding machines, handheld laser welders are compact and user-friendly. With intuitive controls and ergonomic designs, operators can work with precision and comfort, even in tight spaces or awkward angles.

Applications of Handheld Laser Welding Machines in Sheet Metal Fabrication

Handheld laser welding machines are revolutionizing sheet metal fabrication in numerous industries. Here are some of the key areas where they are making an impact:

-

-

Automotive Industry: Handheld laser welders are being used for car body parts, exhaust systems, and other metal components. The speed and accuracy of laser welding make it ideal for high-precision tasks required in automotive manufacturing.

-

Electronics Manufacturing: For industries that rely on small, delicate metal parts, such as in the production of electronics, handheld laser welding ensures that components are joined without damaging sensitive parts.

-

Construction and Architecture: In the construction of metal structures, laser welding provides a reliable and durable solution, even for large, complex assemblies.

-

Aerospace Industry: The aerospace sector demands high-quality metal components that are both lightweight and durable. Handheld laser welding machines meet these requirements, offering high precision and strong welds without the added weight.

-

Why Choose Xianming Laser for Your Handheld Laser Welding Needs?

At Xianming Laser, we are dedicated to providing the best solutions for your welding needs. Our handheld laser welding machines are engineered to deliver unmatched performance, with a focus on quality, precision, and efficiency. Whether you're in the automotive, aerospace, electronics, or construction industry, our machines are designed to meet the most demanding applications.

Our team of experts is always ready to assist you with choosing the right machine for your specific needs and providing ongoing support to ensure smooth operation. With Xianming Laser, you’re not just investing in a machine; you're investing in a reliable, long-term solution for your welding processes.

Conclusion: The Future of Sheet Metal Fabrication

As industries evolve, so does the technology that powers them. Handheld laser welding machines are quickly becoming the future of sheet metal fabrication, offering unparalleled speed, precision, and versatility. If you’re looking to stay ahead of the curve, Xianming Laser's advanced welding solutions are your key to success.

Ready to upgrade your welding processes? Contact Xianming Laser today to learn more about our handheld laser welding machines and how they can transform your business.