Model: XM-Newly designed laser cutting machine

Working area: 3000x1500mm

professional customer service and technical team

Can provide you with 24-hour technical support

provide you with a completeset of machine operation tutorials

Minimum Order Quantity: |

1 |

Packaging Details: |

1.Whole film packaging Sheet fiber laser machine; 2.Anti-collision package edge; 3. Fumigation-free plywood wooden box and pallets with iron binding belt. |

Delivery Time: |

7-40 Days |

Payment Terms: |

TT (Telegraphic Transfer), Western Union, Paypa, Alibaba Trade Assurancel. |

Supply Ability: |

300 Set/Sets per Month |

Minimum Order Quantity: |

1 |

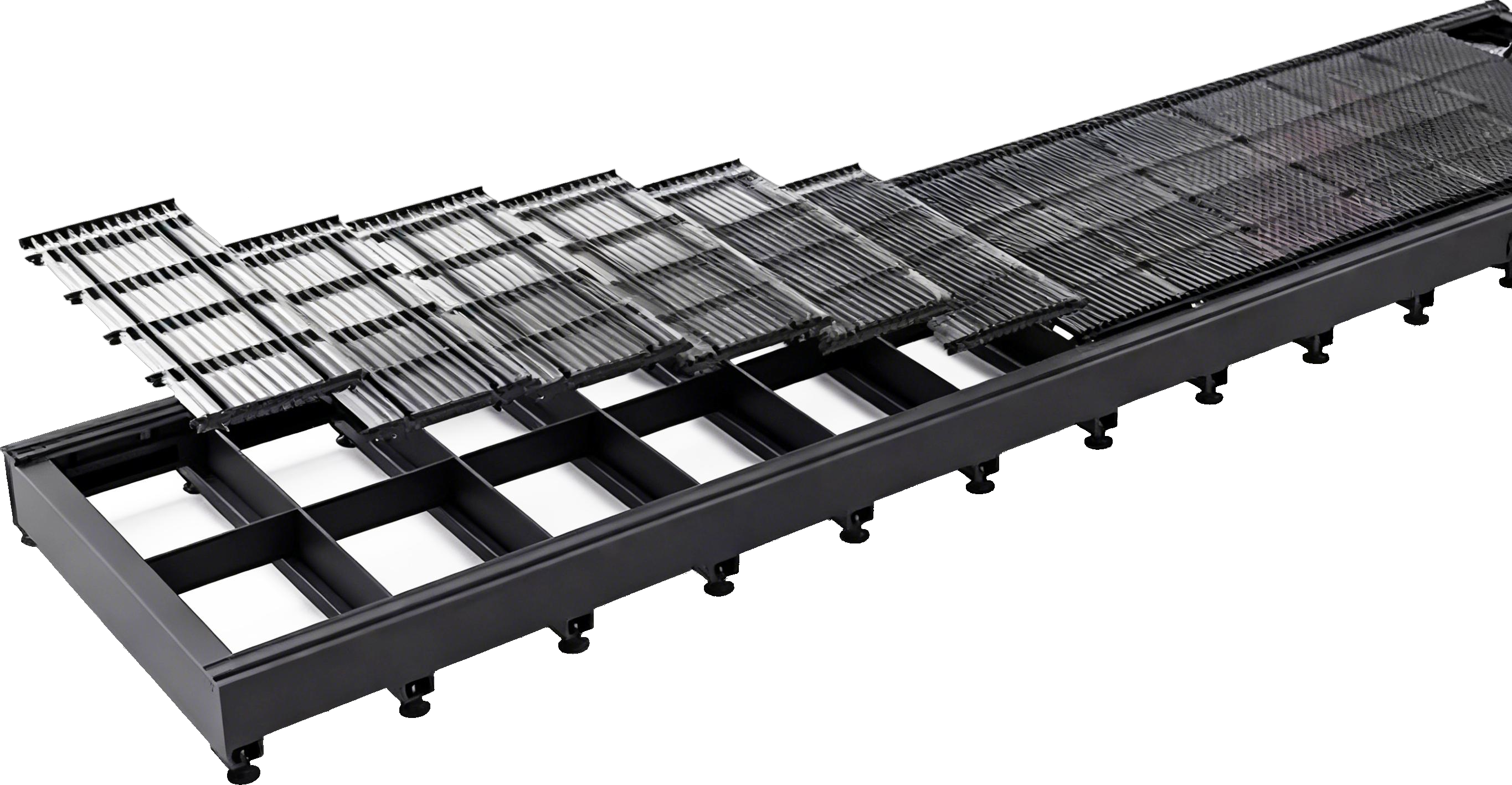

The 12020 large-area fiber laser cutting machine has a customizable bed size and processing length according to customer requirements. It can process a wide range of materials. The large cross-section rectangular tubes have undergone annealing, welding and precision processing to ensure stability and reliability.It is particularly suitable for high-precision and high-efficiency cutting and processing of large- area metal plates.

01. Ultra-large format thick metal processing : The maximum processing size is 2000 mm x 12000 mm. It can easily handle extremely large andheavy metal plates. This significantly speeds up the processing of large components and supportsefficient and large-scale production.

02. Subdivided Fluid Domain Dusting : This smoke exhaust device can automatically detect the position of the laser cutting, therebyprecisely opening the exhaust vents and closing the exhaust vents in the areas that have not beencut, thereby enhancing the suction force.

03. Higher material utilization rate: This software has more space to achieve the optimal layout, and is capable of easily handling those components that are long in length or have irregular combinations

04. Replaceable Independent burn-proof sheet metal: Reduce the erosion of slag injection on the bed and improve the life of the bed.

05. Energy conservation and environmental protection: Because of the high energy conversion efficiency and low energy consumption, it can not only reduce processing costs, but also achieve environmental protection and energy saving.

3 protective lenses,highly effective collimating focus lens protection.2-way optical water cooling extends the continuous working time effectively.

High-precision To successfully avoid step loss,a closed-loop stepping motor is used.The repetition accuracy is 1M and the focusing speed is 100mm/s. Dust-proof to IP65,with a patent-protected mirror cover plate and no dead angle.

Various Brands Of Laser Head Are Available.

Friendess CypCutE 2D cutting software is for medium power EtherCAT cutting system. CypCutE is easy to use, rich in functions, stable and reliable.

It has advanced functions such as "Smooth MicroJoint", "Fast Cutting" and "Circle Center" to meet various processing needs.

The lathed bed is after aging treatment: 1600℃ high temperature heat treatment, 24 hours with furnace cooling and precise co2 protection welding,which ensures along-term stability and no deformation.

No deformation, light weight, high strength Light cross beams allow equipment to operate at a faster rate, boosting processing efficiency and quality.

The light crossbeam allows the machine to move at a faster rate and enhance cutting eficiency.

The aerospace industry's aluminum profile beam ensures that the equipment has efficient dynamic performance .considerably increasing processing efficiency whilemaintaining processing quality.

Servo motors stabilise and drive the beam to control the movement of the XYZ axis according to the programmed instructions to complete the cutting operations with complex precision and the user can adjust the parameters according to their needs.

Professional cutting laser source. With high-quality beam quality, high light conversion efficiency, the light emitting mode is more conducive to achieving a good and stable cutting effect with high quality.

Xianming Laser has successfully registered its trademarks in multiple countries, which meansthat the company has obtained legal protection for its trademarks in those countries. These registrations not only ensure the exclusive use of the company's brand and prevent others from infringing or imitating it, but also provide strong support for the company's expansion in the inter-national market.

The Fiber laser cutting machine are good at processing common metal items in daily life such as advertising metal characters, kitchen utensils, sheet metal decoration, metal plates, etc., The Fiber laser cutting machine are widely used in electronics, electrical, mechanical hardware, new energy, packaging, solar energy, LED, automobile and other industries and also Widely used in cutting stainless steel, carbon steel, alloy steel, copper, brass, silicon steel, galvanized steel, nickel titanium alloy, Inconel, titanium alloy and other metal materials.

Model |

XM-12020 Fiber Laser Cutting Machine |

Working Area |

12000*2000mm |

Fiber Source |

Raycus/Max/Reci/BWT |

Control system |

BOCHU/Raytools |

Laser Wavelength |

1080nm |

Maximum acceleration |

1G |

Laser power |

3000W/6000W/8000W/12000W/20000W |

Compatible software |

AutoCAD,CorelDraw, etc. |

Graphic Format |

DXF/PLT/AI/LXD/GBX/GBX/NC code |

Power supply Voltage |

380V 3Ph, 50/60Hz |

Cooling Mode |

Water Cooling |

Working Life of Fiber source |

More than 10,0000 hours |

Weight |

6T |

Machine Size |

15500*2820*2070mm |

We have professional customer service and technical team.

Can provide you with 24-hour technical support.

We will provide you with a completeset of machine operation tutorials.

1. Warranty for 1 years.

2. Maintenance for whole life.

3. We will provide the consumable parts at an agency price.

4. 24 hours online service,free technical support.

5. Machine has been adjusted before delivery, operation disk is included in the delivery. If there is any other questions, pls kindly tell me.

6. We have manual instruction and CD/U disk for software installation,operation and machine's using and maintenance.

Q1. Before sending me an inquiry on our cnc laser, it is better for you to provide me the following information:

(1)Your metal or non-metal material size. Because in our factory, we have different models accordng to working area.

(2)Your materials.

Metal/Acrylic/plywood/MDF?

(3)You want to engrave or cut?

if cut, could you tell me your cutting thickness? Because different cutting thickness need different laser tube power and laser power supplier.

Q2. If we don't know how to use the machine,can you teach us?

Yes, We will send you manual and guide vedio in English, it can teach you how to operate the machine. If you still can not learn how to use it, we can help you by "Teamviewer" online helpsoft-ware.Or we can talk by phone, email or skype

Q3. How long is the delivery time?

For standard machines, it would be 3-5 days: For non-standard machines and customized machinesaccording to client's specific requirements, it would be 7 to 10 days.

Q4. Quality Control:

The whole production procedure will be under regular inspection and strict quality control. The complete machine will be tested to make sure they can work very well before being out of factory.Our machine passed CE Certificate, meet European and American standard, were exported to morethan 100 Countries.

Q5. Do you arrange shipment for the machines?

Yes. dear esteemed customers, for FOB or CIF price, we will arrange shipment for you.For EXW price, clients need to arrange shipment by themselves or their agents.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog