Step 1: WeldLike this awesome new thing you can weld, or cut with and even sort of engrave metal! The device is a little machine you hold in your hand that uses lasers to cut through materials cleanly and accurately. For any kind of metal worker, it is a great invention. Read more about this awesome tool here — Read the full feature list and how you can use it in YOUR projects! →

With its 3 in one air-cooled laser welding machine, if you work with metal of any kind then... The best part of it is that, you can carry it anywhere with yourself. This is very beneficial if you take multiple jobs at different places. Furthermore, this is precise—meaning you can cut and weld exactly as your need without any errors.

The laser technology in this machine is quite unlike the old welding methods. Rather than relying on fire or a high-voltage electric charge to melt metal, it does so using a laser beam. It is this why the laser can turn it into melted metal quickly and without harm to surrounding areas as well, because: A) This after all may conduct... This is a pretty solid choice for most projects, it mitigates the damage you can do to what you are working on.

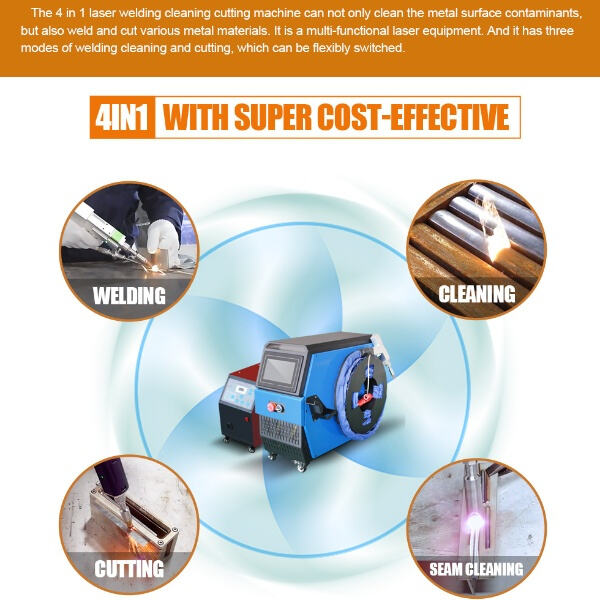

Now let's say you need to take two separate pieces of metal and stick them together, this is where the welding feature would come in. When a metal has to be cut in certain shape you typically desire, this facility is used widely for obtaining the expected perfect contour. For metal work, you can personalize your piece of metal with the engraving feature if you want to add a design or logo or simply some words.

The great thing about this machine is that it functions well with light metal and heavy jobs as well. This is crucial because various welding machines are able to provide a good quality weld circuit only for different metals that have specific thickness ranges. Thin sheets are where some machines strip down, while others only do well with thick stock.

Finally, this machine comes with few additional features that will help you to work more efficiently and effectively in a workshop. For example, you are able to alter the intensity of your laser beam. You can control the temperature of that metal, and this is very useful for various projects.

The speed of the machine can also be tuned, allowing you to work at your own rhythm. Additionally, it offers you the luxury of having variable welding modes — continuous or pulse welding based on your requisites. So all of these extras allow you more control over your work allowing you to make it exactly what YOU want!

Liaocheng Xianming has a 30000sqm manufacturing unit. We have a top r D department within the industry, and now we concentrate on the creation of several types of fiber laser machines.

Liaocheng Xianming produces customers with personalized logos plus videos, images and other materials. Agents also provide customized items by customers. Our fiber laser machine tend to be more advanced than more manufacturers, our main services and products include a wide range of high-powered metal laser cutting machines laser welding machine, cleaning machine, and co2 engraving machine, marking machine.

Liaocheng Xianming gives a lot of attention to after-sales services, knowing that good service fiber laser machines for us is equally crucial. We stick to the principles that are line with customer-centric and global presence. This is made possible by support for the service network.

Liaocheng Xianming Machines an expert logistic packing made to supply quick and efficient transportation methods to users which make logistics considerably efficient. We'll do in order to fulfill your logistics and get the fiber laser machine to where it must become quickly and securely whether you are a person or a small business.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog