MDF medium density fiberboard is what the MDF stands for. It is a unique kind of material that uses wood fibers and a specific type of glue known as resin. A lot of people love an MDF but cannot afford more expensive woodIt is also strong, easy to work with and very affordable. But working with MDF can be tricky. It can be a slow process and difficult to do with conventional tools such as saws. This is why owning one of these laser cutting machines can be so convenient and drastically improve your projects!

From a fun toy box for your child to wall-art that brings color and life into your living room or even custom furniture tailored precisely to your space, with the laser cutting capabilities of these machines you are in control. A laser cutter will allow you to easily create more complicated shapes and other designs than most, such as circuit cutouts or inlays harder designs that would be next to impossible with traditional woodworking tools. That means you can use your creativity!

You can design whatever you like on computer software, if at all your knowledge for the particular field is enough to do so. This allows you to see your project exactly as it will turn out, before ever making the first cut. From there the design is ready to be cut with a laser cutter. The MDF will be cut by the machine according to your own design. This is an amazing way to create personalized gifts or tradings in the house that match your style.

Before we get started the most important things to consider before purchasing a laser cutting machine are as below. The first thing is to determine how much you can afford. A laser cutting machine can be very inexpensive, even a few hundred dollars, to rather expensive models costing tens of thousands. The more information you have about your budget, the easier it will be to eliminate machines that do not meet them.

Then consider how large and powerful you want your laser cutter to be. By now, you have seen that these comparably small machines are good for most DIY projects but if the size of your projects falls somewhere upwards from there then a bigger cutting area would be essential. Stronger blades are required to cut through the material, especially for working with thicker pieces. You want to make sure you are going with the best machine that fits your requirements because it will allow for ease of use on all woodworking work, once decided.

The great thing is that the laser cutting machines are constructed with simplicity in mind. Although the technology can appear to be very complex, many of these tools are actually quite simple to use. Most machines have very easy-to-use software that will let you input your design and control the laser cutter literally in a matter of minutes. Meaning now you can start to create your projects without the learning curve that it entails.

Laser cutting machines are easy to use, and above all else extremely reliable. They are professional-grade and engineered to be exact that means you can typically carry out your tasks with the precision of knowledgeable without spending 1000's mileawayofsorry hours at training. This is fantastic for those who are new to woodworking and they can start making their beautifu pieces right of the bat.

Liaocheng Xianming Machines a professional logistic packaging to deliver quick and efficient transportation services to customers which make logistics more cost-effective. We'll do our most readily useful to make sure the fiber laser machine also includes its destination quickly and properly, regardless of irrespective of whether you're an individual as business.

Liaocheng Xianming includes a 30000 square meters manufacturing facility. We has a r which was top d in the commercial, and we pay attention to the manufacture of numerous types of fiber laser machines.

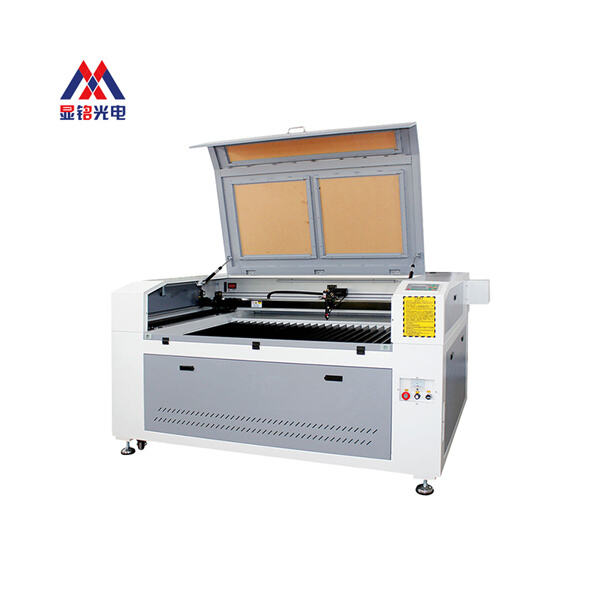

Liaocheng Xianming has the ability to provide customers and company logo as well as other custom-designed and customized agents images of the customer's logo, product videos and other media. Our fiber laser machine higher quality than other providers. Our main items are a complete array of high-power metal laser cutting equipment since well as laser welding machine cleaning machine, and co2 engraving machine marking machine.

Liaocheng Xianming will pay particular attention to after-sales support, knowing that providing a good service fiber laser machines for us are equally vital. We will follow the principles in keeping with a global and customer-focused presence. This is made possible with support network services.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog