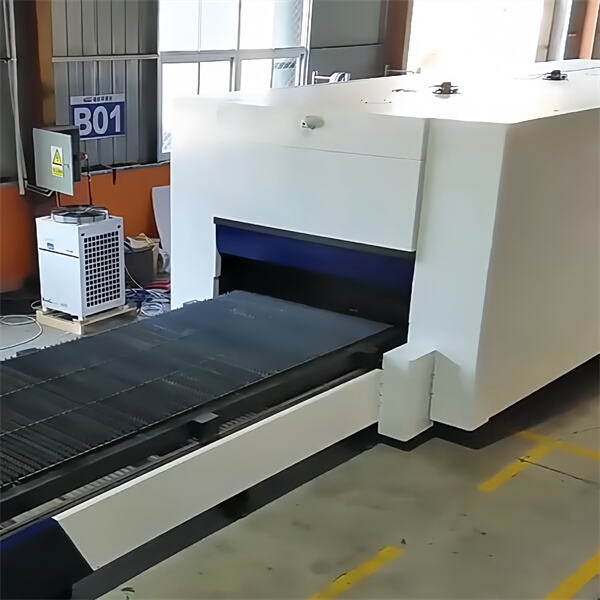

Another machine that would become crucially more professional is the aluminum fiber laser cutting machine. Indeed, it can cut metal fast and precisely, and the reason why it is so important is that it enables you to cut various shapes with much less effort. Aluminum fiber laser cutting machines now enable you to cut complex shapes and design that otherwise would be much harder to create. What is more, the reason that these machines make a difference is that they can cut very weak and thin metals so fast that you can cut a lot of levels at once. They make a difference in terms of design.

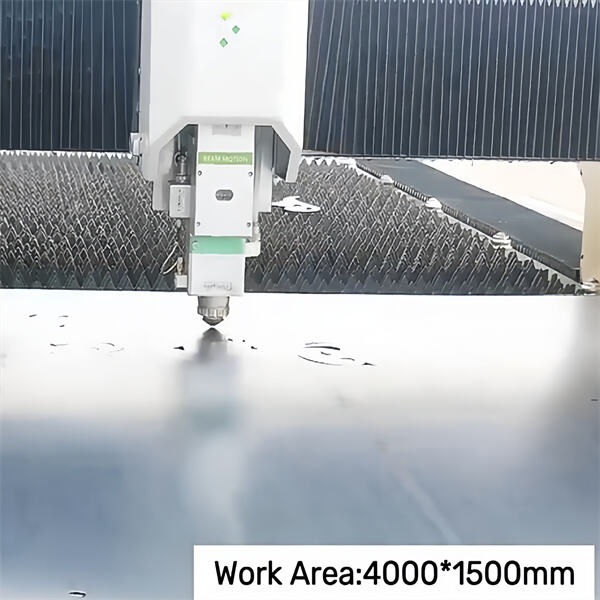

So, how does it work, why do these machines make a difference? These machines work by melting and vaporizing the metal with a high-intensity ray of light. This method gives a much higher level of precision in planning where to cut and on what path than using a mirror a saw. By using a computer the machine gains a very high degree of precision, and it can make complex shapes and designs due to this.

So, this shows how the technology in the molding industry, represented by the aluminum fiber laser cutting machine, played a major role in that. How dramatic changes of new machines and tools significantly changed the way products were produced and in the process, they made the production faster and much more precise and accurate. How in manufacturing, there were cost cutting operations because product achieves the market faster and the buyers pay a lower price.

That would be what it means, in a few words, to use an aluminum fiber laser cutting machine. What are the key benefits of using this machine, is the time savings when producing most products. It is, indeed, a very difficult job using old school techniques. But with a fiber laser cutter you replace the rough production to a manufacturing relatively easier and less costly machine produce in tighter deadlines products. It is very important because it is much easier for example for a company to achieve their objectives.

Aluminum fiber laser cutting machines work by melting and vaporizing the metal with a high-intensity ray of light, providing an accurate cut. This gives a much higher level of precision in directing the cutting path than traditional methods using blades or saws. It allows for the manufacture of complex shapes and patterns within a high degree of precision.

This is what we call the profound influence of technology on manufacturing industry, represented by aluminum fiber laser cutting machines. The continued innovations of new machines and tools had greatly changed the way products were manufactured, enabling a faster and more efficient process with extreme accuracy. This leads to cost savings that companies can funnel down the line towards lower prices for consumers which improved efficiency allows these entities produce more output in less time.

One of the benefits for why it is a great idea to use an aluminum fiber laser cutting machine when carrying out manufacturing processes, comes in time-saving. Processes involving metal cutting can be taxing and time consuming through old school ways. On the other hand, a fiber laser cutter redefines production relatively simpler and less time-consuming for unveiling products on tight schedules. This increase in productivity is a key success factor for companies to accomplish their objectives efficiently.

If I were to briefly explain the advantages of using an aluminum fiber laser cutting machine, it could be this. These machines are widely used for fast and accurate cutting of various metals, making it possible to create complex patterns and shapes. They also improve productivity and efficiency which helps the companies to achieve their goals by reducing operational costs. This is great news as manufacturing will only continue to improve thanks to modern technologies and be able to produce more turnkey products for less money.

Liaocheng Xianming machines sales plus marketing network that spans over 60 countries and regions. It provides a professional logistics process that provides customers with quick transportation services, making sure logistics gets to be more convenient. Regardless of whether your are the consumer or simply business we are going to endeavour to be the ideal at meeting your needs and acquire the fiber laser machine to where it requires to securely be quickly and.

Liaocheng Xianming has a 30000 square meters manufacturing facility. We have a top r D department in the commercial while focusing on the developing of numerous types of fiber lasers.

Liaocheng Xianming gives a lot of attention to after-sales services, knowing that good service fiber laser machines for us is equally crucial. We stick to the principles that are line with customer-centric and global presence. This is made possible by support for the service network.

Liaocheng Xianming can provide customers with logos along with other personalized and branded agents pictures of merchandise featuring customer, video and other materials. The fiber laser machine is much better to other manufacturers.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog