IntroductionCNC metal cutting laser devices are the latest models of machines used for specific profiles within an object, and from stainless with square-cut measuring a variety materials. Using a computer technology that makes precise cuts, it now grants us the ability to create parts with very intricate designs - something that would have been nearly impossible had we not used traditional metal cutting methods.

Most CNCmetal cutting laser machines are that employ is a computer-controlled light beam. With a laser beam the metal is cut faster and with minimal human intervention by following strict orders generated on a computer. With this level of fine tuning, you can expect no less than pristine cuts even on highly intricate designs. CNC lasers for metal cookies are gaining popularity due to their capability of high-grade precision.

CNC laser cutting is far better than the traditional metal reduction procedures plus sawing and shearing. One of the advantages was amazing accuracy that laser cutting offered, a paper-thin cut which had never been reached. Furthermore, setup time and efficiency are aslo advantages of the CNC laser cutting machine. They also yield minimal scrap and cleaner edges on metal than traditional cutting technologies.

At completion, the process is also used in a host of other modern technologies we use nowadays such as CNC cutter equipment from laser metal cutting.

CNC laser cutting machines type#sheet metal processing equipment have brought a lot of convenience to the manufacturers during their process. They are faster than their counterparts and they will accumulate time savings on production as the produce goods. Moreover, they are capable to create sophisticated shapes hence no additional cutting activities needed which ultimately uncomplicated the production process. The measurements of the CNC laser cutting machine still hold their accuracy, which allows for less retooling to be done and therefore work can become more efficient as well. Moreover, these devices can cut several sheets of metal during one program which leads to rising the level of high production.

Saves Time and Money: Last but not the least, the increasing number of applications seeking precision metal cutting solutions is a clear sign that CNC laser cutting will become essential in charting how manufacturing moves forward. Each technological advance will only reinforce this fact that tomography aimed at correct and consistent cutting is of the essence for efficiency in manufacturing. It can be clearly stated that here in this aspect CNC laser cutting machines are the way to go as they not only makes sharper and more detailed cuts but it does so by using minimal human intervention. CNC laser cutting will be a common denominator in any work based metalworking as the industry grows and accuracy approaches further.

Such wonderful designs benefited most for the cutting accuracy and precision of these CNC machines, thus saving this beautiful laser cutter operation among such industrial practices and also keeping it with a number about metal art pretty design. Machines that can produce drawings with such intricate detail is due, in part to the technology and skill of these machines as they are incredibly accurate. CNC laser cutting, because it is so versatile and particularly good at creating intricate designs, the applications of metal work with CNC machining have been greatly expanded. The applications of this CNC laser cutting technology are endless and with the metal art lifetime is huge to satisfy all your creative designs.

So which is why CNC metal cutting laser machines are very awesome in manufacturing and Metalworking world. Robots are invaluable tools in many industries for their precision, speed and other inherent benefits. As these technologies become more advanced, so too will CNC Laser Cutting and consequently the application possibilities for this technology also seem to expand with time making it a virtual shoe-in as THE future of the metalworking industry. It should come as no surprise then why CNC laser cutting machines have infiltrated so many different sectors of the manufacturing and metalworking worlds given you can get an edge from much of what has been discussed previously.

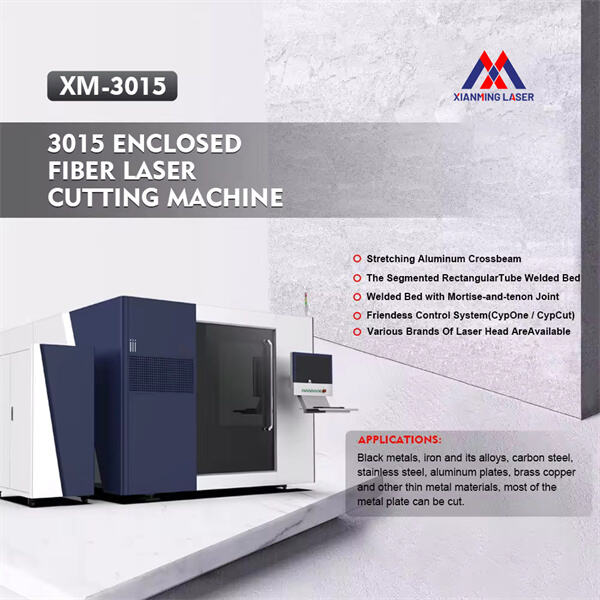

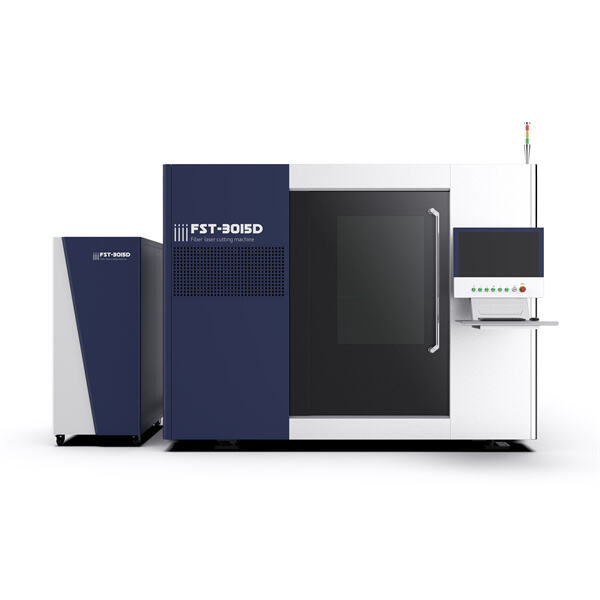

Liaocheng Xianming machines marketing and sales network spread across a lot more than 60 countries and regions, has a professional logistics process provide customers with quick transportation service therefore that logistics can be made more convenient. We are going to try everything to make sure that your fiber Laser machine reaches its destination efficiently and swiftly, regardless if you are a private person a small business.

Liaocheng Xianming has a 30000sqm manufacturing unit. We want the top r D department in the industry, therefore we look at the creation of various kinds of fiber lasers.

Liaocheng Xianming will pay particular attention to after-sales support, knowing that providing a good service fiber laser machines for us are equally vital. We will follow the principles in keeping with a global and customer-focused presence. This is made possible with support network services.

Liaocheng Xianming gives customers with personalized logos and videos, graphics plus materials. Agents could also provide customer-branded products. The fiber Laser machine are a lot better than other manufacturers.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog