Under such this circumstance, the opening of a kind of advanced and high-tech product -- CNC metal fiber laser cutting machines are known to every family,on-street talking.While at home using as well in commercial applications that involve many types products now required manufacturing robots,automobiles,colleges & universities,research facilities,it just seems aircraft impose strict performance requirements. These tools have literally taken the production field around its head and produced with it. At present, we will continue our debate to expose much more advantages as well as disadvantages output profit part limit and less complicated production with steel fiber laser cutting equipment.

Performing exceptionally well, particularly metals plastics e.t.c. and many businesses employing CNC metal fiber laser cutting machines one of the most significant features is that their high precision outputs comprise another key consideration as to why they are used by companies for production or construction applications. These machines can work at quicker speeds and are more productive than the human contemporary manual labour. The laser beam overtakes even the thickest metal sheets and high-speed precision cutting at a level not previously achieved since it comes with an exited gas state duration that is very short. In addition to this, because they are backed controlled by a computer system that makes them very automated and so only low chances of any error happening due to the human being also. In industries like aerospace, automotive and medical instrumentation where accuracy and precision play an important role; this automation is beneficial.

When it comes to productivity there is no other solution that could provide better results than a CNC metal fiber laser cutting machine. In very short time, these can become the best solution replacing traditional cutting, drilling and engraving. They are able to perform operations such as cutting metal sheets, a task that would require other machines hours instead in mere seconds. It has been observed recently that there is a considerable reduction in machining time of industrial business like aerospace and automotive when tools such as CNC metal fiber laser cutting machines are used to reduce the cost excessively. Complex parts and components can now be made faster than the previous time allowing for prototyping, testing out with through development phases.

CNC based metal fiber laser cutting machines can perform ultra-precise, premium quality cuts in multiple materials such as metals, plastics and composites etc. But it is the malleability in design, where complexity and detail can be incorporated into models that makes them unique from other devices at large. In addition, CNC programming eliminates boundaries and allows completion of projects in a fairly short period (9). CNC metal fiber laser cutting machines are actually like having a superpower and have changed the way things were made. Simplification of the manufacturing process Cnc Metal Fiber Laser Cutting Machine

CNC fiber laser cutting machine and Replacement of Human Labor With the advent of this based CNC plasma engraving tools, a drastic change happened in how we were carrying out our manufacturing processes. Programming of the CNC can allow it not only to make a thing but also to edit and finish up. From there the CNC machine can take care of everything with minimal to no maintenance required beyond receiving that initial design. Before, the manufacturing process depended on operator experience, abilities and regular monitoring. Yet, CNC metal fiber laser cutting machines do not need human supervision to operate (11). Manufacturing Process Changes By the CNC Metal Fiber Laser Cutting Machine

This has resulted in improved manufacturing with their technology, so parts production efficiency and the creation of waste have decreased. Now things are even more complicated and the numbers of products that can be built, whether they are intended for aerospace or cars, gadgets or meditech continue to expand. The result is better finished items created faster than ever before. In addition, CNC laser machine may be used to manufacture items that could not previously have been (e.g.: custom jewelry, trophies or plaques) and it is now simple and fast (14).

In a nutshell, The CNC metal fiber laser cutting machines are technically an asset which have made manufacturing easy by saving time and energy meanwhile with the increase in product quality. For an example, these precision machines can create detailed designs which are impossible manually without automation for manufacturers and unmatched both in accuracy as well as perfection. As a result of the continuous improvement that has taken place in automation tools and standardization levels with artificial intelligence - currently led by CNC metal fiber laser cutting machines, we are progressing towards an era where much of our hopes for manufacturing enhancements can find their way to fruition quite easily.

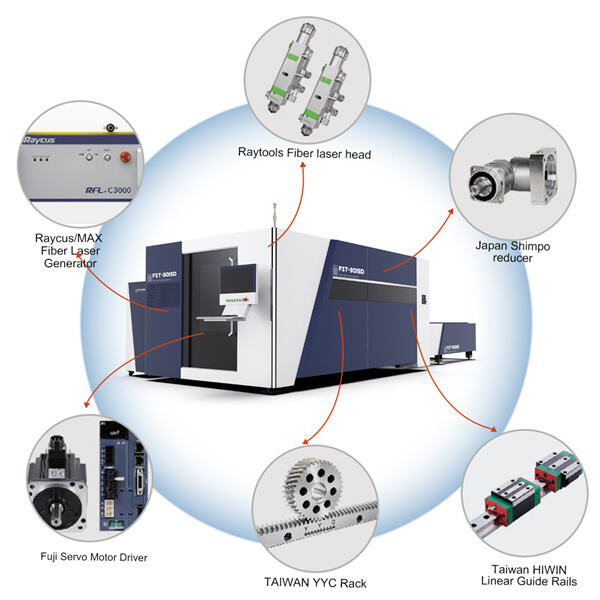

Liaocheng Xianming covers a spot of 30000 square meters in the factory, is sold with a D r excellent team the field, plus is concentrated regarding the creation and development of varied kinds of fiber lasers. We have many patents being technical and contains now passed on the IS09001 quality management certification aswell as European CE certification plus FDA certification.

Liaocheng Xianming can provide clients and logos as well since other personalized and agents with images for the customer's logo, product, videos as well as other items. Our fiber laser machine has a top quality than|top quality} other providers, our primary merchandise include a wide range of high-powered metal laser cutting machines, laser welding machine, cleaning machine, and co2 engraving machine and marking machine.

Liaocheng Xianming machines market and sales community across over 60 countries plus regions. It is a very efficient logistics packaging procedure that provides speedy transport to your visitors in order for logistics try made easier. It does not matter if you should be the user or a company We do our better to meet your requirements plus transport the fibre laser machine to where it takes to securely be quickly and.

Liaocheng Xianming Pay close time to after-sales customer service, understand that quality service and quality fiber laser machines is same important for us to adhere to the principles of keeping with our customer-centric, global presence that is enhanced by service network support, and will be 24-hour on-line service. We will strive to offer the our customers with superior products and superior service.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog