Discover the world of dual table fiber laser cutting technology for manufacturing.

Have you ever really thought about the massive process of making the stuff we use daily? But the trappings we depend on are often made with machines designed to cut, mold and hone materials at increasingly minuscule levels. The Dual Table Fiber Laser Cutting Machine remained as one of these futuristic machines

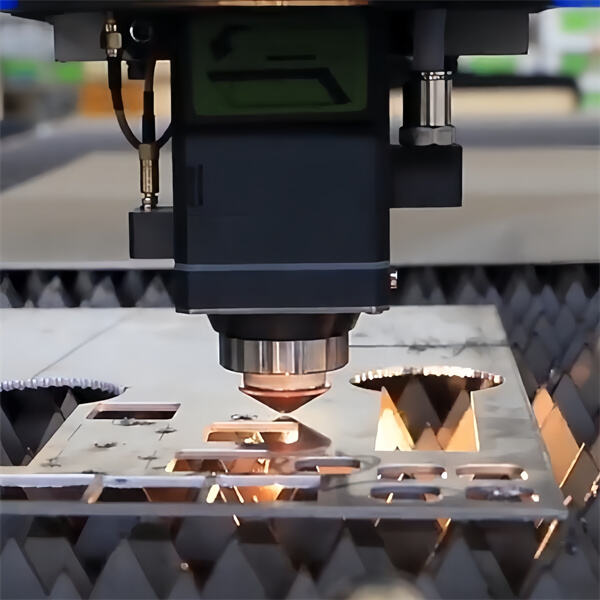

The Dual Table Fiber Laser Cutting Machine is a mark of technological progress, which ensures defect free top class product on the run. This machine offers precision manufacturers cutting exact specifications and intricate designs made possible via advanced fiber laser technology which ensures minimum wastage. The Dual Table Fiber Laser Cutting machine also proves its flexibility when tasked to cut a wide range of materials from all sorts of metals, plastics and even wood.

The traditional manufacturing processes are usually very cumbersome and time-taking. But now, the Dual Table Fiber Laser Cutting Machine enters as our only saving grace to automatically increase your productivity two-folds. They have dual table systems that can cut two materials at the same time, which help to minimize cutting times from material changeover between cuts and save on overall production time. The immediate result of this is that the businesses will be able to reduce their turnaround times and also increase final product output proportionately.

Additionally, this device has automatic loading and unloading to help increase the productivity of your production line. All in all this forward-thinking machinery drives productivity across the board for a variety of industries, offering quicker and more cost-effective production runs.

What if you were designing jewellery rings or complex industrial upgrades and merely pressing a button was enough to bring the marvels into life? Dual Table Fiber Laser Cutting Machine has made high precision cutting a reality This state-of-the-art machine combines cutting accuracy far superior to traditional methods, able as it is of achieving the most intricate detail and tightest tolerances.

This is a significant difference as far more advanced technology can be found in this very dual table fiber laser cutting machine than those commonly used conventional sets of the tools without it. One of the main advantages behind it, is that its fiber laser beam gives incredible precision no matter how detailed your design. Industries that require very high levels of precision, for instance in aerospace or medical applications often have very strict tolerances they must adhere to if their products are going to function as intended.

And with the advent of Dual Table Fiber Laser Cutting Machine, a cutting technology that will transform manufacturing and bring unique options for most straight cuts. Its precision and repeatability are an unprecedented level for many industries that deal with complex design work.

However, one of the main contributions that this machine began to bring in this area is the reduction of residual waste and material loss when manufacturing. Operated with less power, the Dual Table Fiber Laser Cutting Machine cuts cleanly and produces minimal waste materials, saving on overall production costs while minimizing carbon emissions at additional low-costs.

If you are looking to increase your productivity, the slow traditional way of cutting can be frustrating. But in the age of Dual Table Fiber Laser Cutting Technology, nothing is impossible. Brings precision and efficiency together into place! This automated loading and unloading system of the machine reduces man hours as well helps in fastening the manufacturing process. What's more, the ability to cut multiple designs in one go saves time and money.

In summary, the Dual Table Fiber Laser Cutting Machine is one of a kind and next-level resource for manufacturers that value precise craftsmanship, optimizing their operations through innovation to greater levels. With the ability to quickly create and accurate, efficient in creating complex 3D-models which set it first place worldwide. I wonder if one of these machines will show up at your home shop in the near future?!

Liaocheng Xianming covers an element of 30000 square meters into the factory and has now a D r top team the field, and is concentrated in connection with development and creation of types of fiber laser machines. We've several patents being technical have obtained the IS09001 quality management certification as well since European CE certification and Food And Drug Administration certification.

Liaocheng Xianming Pay close time to after-sales customer service, understand that quality service and quality fiber laser machines is same important for us to adhere to the principles of keeping with our customer-centric, global presence that is enhanced by service network support, and will be 24-hour on-line service. We will strive to offer the our customers with superior products and superior service.

Liaocheng Xianming has the ability to provide customers and company logo as well as other custom-designed and customized agents images of the customer's logo, product videos and other media. Our fiber laser machine higher quality than other providers. Our main items are a complete array of high-power metal laser cutting equipment since well as laser welding machine cleaning machine, and co2 engraving machine marking machine.

Liaocheng Xianming Machines provide a professional packing was logistic built to provide fast transportation services for customers and making logistics easier. We are going to try our easier to ensure that your fiber Laser machine reaches their destination quickly and safely, irrespective of no matter whether you are an ongoing company an individual.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog