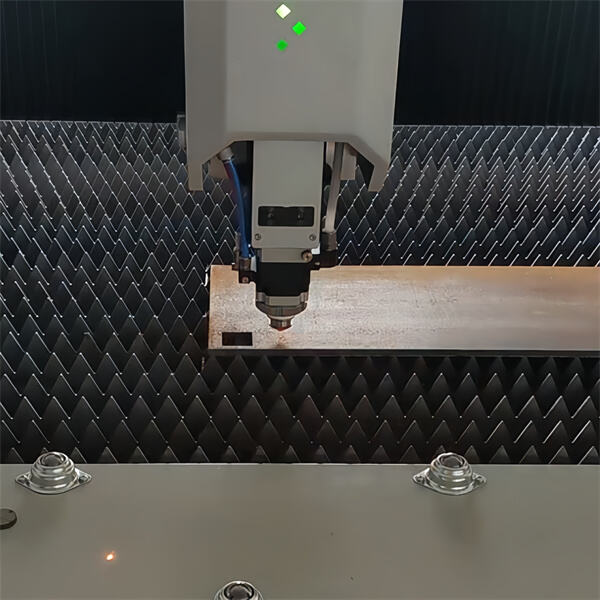

One spectacular and advanced method of using a laser is Laser cutting (you must be familiar with this term) where it emits intense light energy in the form of photons beam directly onto a material that needs to get sliced. This is not only intriguing but also a necessity in the world of manufacturing for multiple reasons. The other part is its detail and precision allowing you to strip it down into the smallest of details with no problems. Moreover, its speed of operation equals mass production. Additionally, it guarantees the cutting tools are long-lasting life as a contact-less method.

This makes it highly versatile, with the added benefit of being applicable to a wide range of materials like stainless steel, aluminum0.5mm: Mild Steel 1 It can also be utilized for more delicate projects due to it is accuracy, such as getting a muted sign created from metal so an option of making that wooden model you always wanted in the specific shape and form.

Laser cutting has revolutionised the manufacturing industry with its high speed, precision and overall efficiency. The advancement in laser cutting can easily be reflected by the new machines that have been emerging into the industry due to them. With these tools, manufacturing plants can produce the best quality items will no waste. Not just this these machines running 24 hours a day is also another way by which turnaround times are decreased and customer satisfaction can be improved.

Laser cutting has mirrored great effects on the variety of fields across diversified industries. For instance, in the automotive sector laser cutting is applied to produce intricate parts with tight dimensional specification down small tolerances. Similarly to the above, in Medicine,laser cutting is used for producing highly accurate implants and other medical instruments. Uses of Laser Cutting in Industry One main benefit with a laser-based alternative is that the machinery allows high speed production and more productive performance for small enterprises when compared to other competing companies, thus allowing smaller firms overtake bigger ones.

In the present scenario, when it comes to tracking with world of laser cutting there are a couple of specific pointers that every one considers, Different types of lasers can be used to cut different materials and so checking that the laser you use is suitable for cutting whatever material it will contact with, e.g. CO2 lasers cutting plastic wood paper & fibre etcetera; And appended rows! It can not work because the weight of stuff below a cold saw is crucial as each machine has various thrusts.

An and also in sight is that Laser cutting.. process need not the material being cut to be clamped down. These materials have the risk of cracking in clamping force, which so laser cutting is a good choice for them. And with no tooling required, this makes laser cutting quicker to set up than a power press or other method of metal work; perfect for low volume production in larger quantities.

Conclusion: As a summary of the upcoming Laser cutting concept in the manufacturing sector is fantastic. Its accuracy, speed and flexibility packaged with its ability to grow means that this could well be a dominant force in production from automotive and medical through all the way down to toys.

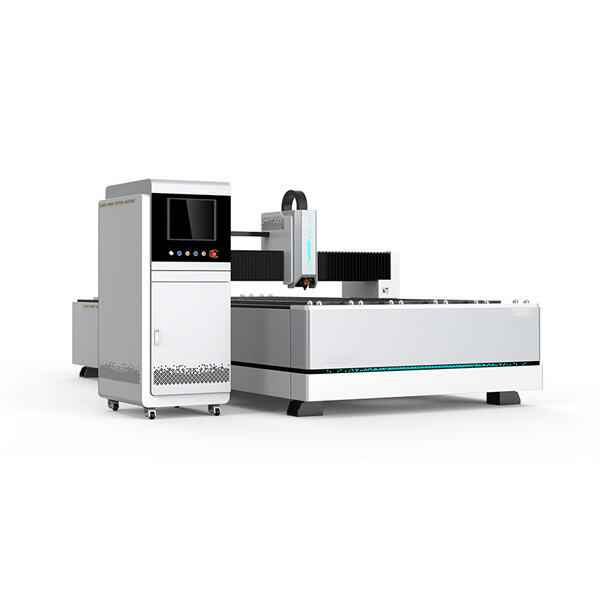

Liaocheng Xianming can provide customers with logos along with other personalized and branded agents pictures of merchandise featuring customer, video and other materials. The fiber laser machine is much better to other manufacturers.

Liaocheng Xianming machines marketing and sales network spread across a lot more than 60 countries and regions, has a professional logistics process provide customers with quick transportation service therefore that logistics can be made more convenient. We are going to try everything to make sure that your fiber Laser machine reaches its destination efficiently and swiftly, regardless if you are a private person a small business.

Liaocheng Xianming has a 30000 square meters manufacturing facility. We have a top r D department in the commercial while focusing on the developing of numerous types of fiber lasers.

Liaocheng Xianming pay much pay attention to after-sales services, and know that a good after-sales service and high quality fiber laser equipment is same important for us will adhere to the principles of keeping with the global, customer-focused presence bolstered by the support of service networks, and it will offer 24/7 on-line service. We will strive to offer the customers with more superior products and superior service.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog