Metal used to be cut by becoming a black smith. For many years, workers used basic tools such as hand saws and hammers to trim metal parts into the right shapes. This was slow and painstaking work. However, with technology there is now a faster and better way to cut metals. The new process utilizes a special machine known as the laser cutting device!

Metal laser cutting machines are powerful tools that use a mighty laser to cut through metal. Today, these machines are able to perform tasks that previous methods cannot. Using these machines instead of the traditional methods has several advantages. First, they are much faster. In the case of hand methods, it would take hours or days to complete manually what laser machines can cut metal in just a few minutes. Now this is a speed that can be really useful to some factories where metal parts needa mass produced as quickly.

Second, a laser cutting machine has great precision. They can also engrave metal with incredible accuracy so the finished product appears a lot cleaner than anything that is made by hand. In fields like aerospace, this is of the highest importance because anything lees than perfect fit can cost lives or impact performance. Precision, You know its quite important when making airplanes.

Laser machines are multifunctional getLast but not least, the laser Last access [better than others we have written recently] is a very versatile bed cutter. A laser can cut almost anything, including steel, aluminum and copper. They can be using on different types of metal, and in varying thicknesses which makes it great for many jobs. This allows manufacturers to flexibly employ a single machine on several different jobs.

Laser cutting machinesThe advent of laser based CNC metal fabrication equipment has led to radical changes in the way we cut sheet, plate, and tubing. Such machines have obviated almost all the way which are been developed in order to make work faster, more precise and capable of doing many different tasks than traditional formers. Older methods are far, FAR less safe. Laser cutting reduces the risks of workplace injuries since employees do not have to handle sharp tools or dangerous machines.

No matter what industry, the use of laser cutting machine are indispensable. As an illustration, components made for airplanes and spaceships have to be perfect. They might even work on forming metal pieces for vehicles to ensure everything fits perfectly. What is more, these machines also find a place in architecture as well as construction where they are used to give interesting metal shapes that enhance the beauty of buildings and other projects.

The biggest benefit is how well laser machines operate. For manufacturers, this ability to quickly cut through metal translates into significant time and cost savings. Completing parts faster helps companies manufacture more components in lesser time that contributes towards higher revenue.

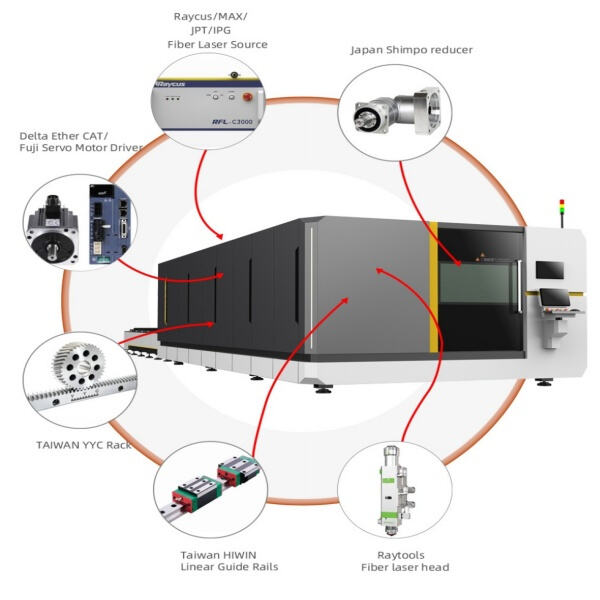

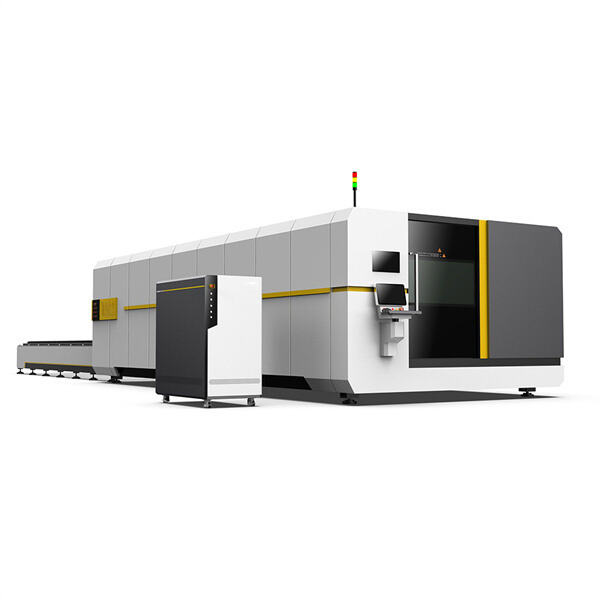

Liaocheng Xianming produces customers with personalized logos plus videos, images and other materials. Agents also provide customized items by customers. Our fiber laser machine tend to be more advanced than more manufacturers, our main services and products include a wide range of high-powered metal laser cutting machines laser welding machine, cleaning machine, and co2 engraving machine, marking machine.

Liaocheng Xianming has a 30000 square meters manufacturing facility. We have a top r D department in the commercial while focusing on the developing of numerous types of fiber lasers.

Liaocheng Xianming pays much attention to after-sales and support services, knowing that having the quality of service provided by fiber-laser machines for us is equally vital. We will follow the principles in keeping with a global and customer-focused presence, which is bolstered by support for the service network.

Liaocheng Xianming machines markets and sales network that spans over 60 countries and regions. It has a professional logistics procedure, which supplies customers with quick transportation services, ensuring that logistics is much more efficient. We are going to try our safer to ensure which their fiber Laser machine gets to its destination quickly and safely, no matter whether or otherwise not your are a client given that business.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog