Surely you have heard of laser cutters that are designed for cutting thin metal sheets? Laser cutters are highly sophisticated machines which use an extremely powerful bean to easily slice through metal. Like running a giant pencil across metal sheets to both mark lines and cut accurately.

Laser cutting is a great way to intricately cut light metal sheets. It also has the ability to design much more detail in patterns. In this article, we will define a comprehensive guide to help you with learning how easy it is laser cutting thin metal.

Make sure your metal sheet can be prepped by using cleansing it very strong and eradicating any debris or oil. This step is so important that it becomes a prerequisite for easier cutting.

Once the laser settings have been chosen based on a material type and thickness, adjust them to obtain the best performance.

Begin the cutting process as per your desired pattern and design so that laser cutter can do its work in a systematic way.

Here are things to take into account when picking the right laser cutter for thin metal:

Power: The more powerful the laser, the thicker metal it can cut through efficiently. A powerful laser may not be needed for thin metal sheets.

Working table: The space on which the metal sheet will fit and referred as working bed size.

Accuracy- although all laser cutters offer pretty good accuracy, some more than others. Choose a model according to your precision.

Price: There is a huge range in how much laser cutters can cost, so you want to make sure you get one that fits within your budget.

Laser cutting allows the incredibly accurate way of slicing through thin metal sheets. This is why it finds its utility also in various designs and patterns. This is our experience of laser cutting thin metal, and here are some key considerations to bear in mind if you want to solve the puzzle.

Metals: Laser cutting is compatible with several types of metals, such as stainless steel, aluminum and brass Now, while all metals can be cut by lasers, some offer more resistance when the cutting process is to be carried out.

Design : Feel empowered to create a design that is uniquely yours or even browse designs online, helping your imagination steer.

Safety: -Exercise the utmost caution since this laser beam is exceedingly powerful and should be kept well away when not in use. Follow all safety protocols, read the instructions thoroughly and ensure that you have adequate protective gear.

Keeping Them in Running Condition: As with most things, Laser Cutters need regular maintenance to keep them working just as well years down the line.

Free Your Inner Artist With a 2000W Fiber Laser Cutter For Thin Metal Materials

Laser cutters are an essential for any craft hobbyist or creator. You can use them to make all kinds of things, from jewelry and signs to Christmas ornaments! Check out these ways to get into thin metal projects:

NameplateCut out your name or initials from a thin metal sheet using a laser cutter and use is as keychain or bracelet charm.

Fashion Earrings: Cut out different shapes and designs from thin metal sheets depending on the fashion, a combination of more metals & colors can be done here.

Final announcement of our elements presented as wall art: Create stunning signs or pieces of life-like ornamentation for your living space by cutting beautiful designs, vectors with detailed engravings out from thin metal sheets.

Christmas Ornaments: Add a merry touch while releasing your stress by cutting some prepossessing shapes from a piece of thin metal sheet to embellish up ornaments for Christmas tree!

As you can see, laser cutters are a very nice tool for cutting thin metal sheets accurately and cleanly. For all their creative potential, these machines must also prioritise safety measures and be kept on the regular maintenance list. If you have a passion for metalworking, this also might be the device that will help to turn your ideas into reality the same as For professional Rolling machines Australia and some more types of equipment.

Liaocheng Xianming Machines provide a professional packing was logistic built to provide fast transportation services for customers and making logistics easier. We are going to try our easier to ensure that your fiber Laser machine reaches their destination quickly and safely, irrespective of no matter whether you are an ongoing company an individual.

Liaocheng Xianming gives a lot of attention to after-sales services, knowing that the quality of service provided by fiber-laser machines for us are equally crucial.

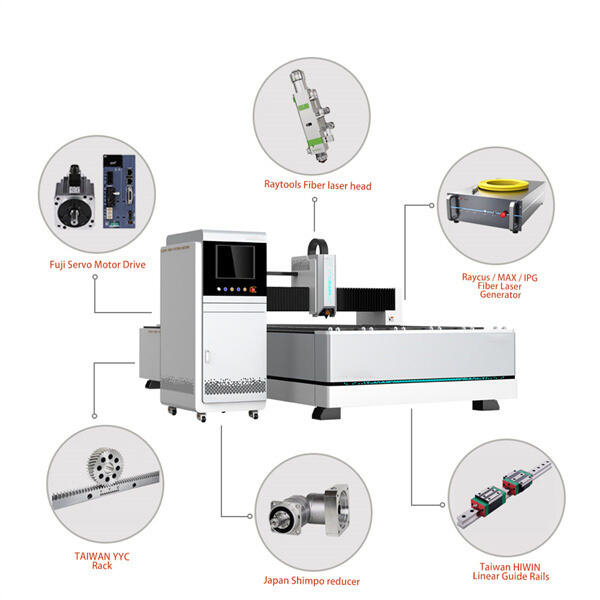

Liaocheng Xianming covers a spot of 30000 square meters in the factory, is sold with a D r excellent team the field, plus is concentrated regarding the creation and development of varied kinds of fiber lasers. We have many patents being technical and contains now passed on the IS09001 quality management certification aswell as European CE certification plus FDA certification.

Liaocheng Xianming has the ability to provide customers and company logo as well as other custom-designed and customized agents images of the customer's logo, product videos and other media. Our fiber laser machine higher quality than other providers. Our main items are a complete array of high-power metal laser cutting equipment since well as laser welding machine cleaning machine, and co2 engraving machine marking machine.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog