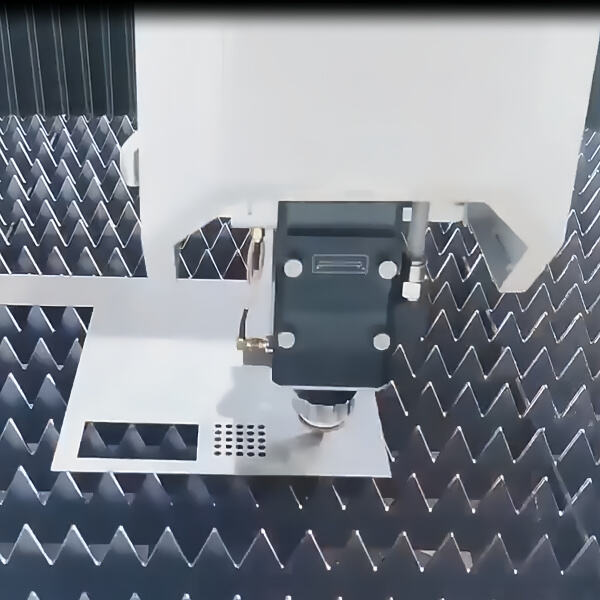

Such tools are laser cutters and for years they have helped in completely revolutionizing the process by which aluminum is typically cut. These machines use a focused beam of light to heat the aluminum until it melts. Laser Cutting - it is a process which cut materials with the help of laser technology and that is able to slice quickly than traditional techniques as sawing or grinding.

For example, laser cutting machines have opened up a universe of new possibilities with aluminum materials. With these machines, it is possible to perform precise cutting on aluminum sheets and profiles which can be used in a vast number of products It finds applications in almost every field today, including but not limited to the fabrication of car parts and building airplane wings; situations where cutting aluminum was quite cumbersome until this miracle option came into existence.

Advanced laser cutting machines bring vast time and cost savings, which is one of the most important benefits that come with using them in aluminum fabrication. Aluminum processing enables these machines to cut parts faster and more precisely than previous methods. This higher efficiency means faster production, and potentially greater profitability for businesses.

In addition, the advent of automated laser cutting machines has improved aluminum cutting procedures than ever. This relieves human operatives of much of the pressure as well, once they have set about adjusting their settings you are free to allow these advanced machines to return and resume cutting by themselves. Automated laser cutting machines reduce the scope of human error and are used to produce aluminum products in an efficient manner retaining quality readings.

To summarise the use of laser cutting machines for aluminium fabrication is really great. These machines not just save time and money, but also help produce the products of high quality. If you need to streamline your production process or increase the quality of aluminum pieces, investing in laser cutting technology is a great decision.

Liaocheng Xianming Machines an expert logistic packing made to supply quick and efficient transportation methods to users which make logistics considerably efficient. We'll do in order to fulfill your logistics and get the fiber laser machine to where it must become quickly and securely whether you are a person or a small business.

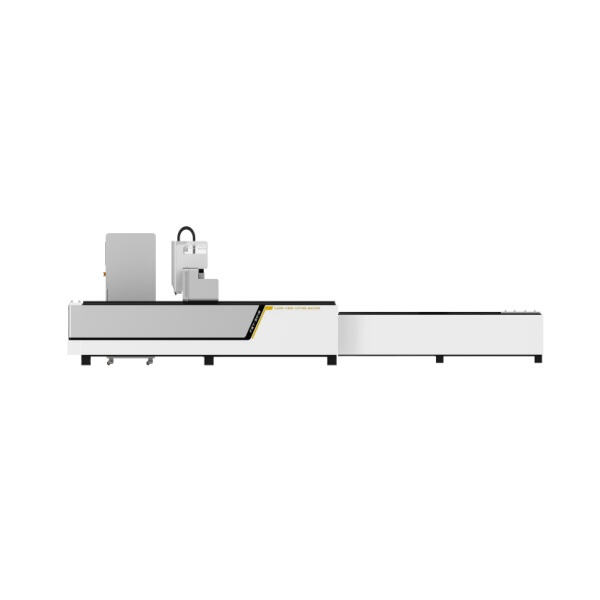

Liaocheng Xianming produces customers with personalized logos plus videos, images and other materials. Agents also provide customized items by customers. Our fiber laser machine tend to be more advanced than more manufacturers, our main services and products include a wide range of high-powered metal laser cutting machines laser welding machine, cleaning machine, and co2 engraving machine, marking machine.

Liaocheng Xianming covers a location of 30000 square meters factory is home to an outstanding r D team in the business enterprise. These are typically dedicated to the development and creation of numerous kinds of fiber lasers. We now have several patents that could be technical. We've been awarded the ISO9001 quality management system certification and european CE certification certification.

Liaocheng Xianming pays much attention to after-sales and support services, knowing that having the quality of service provided by fiber-laser machines for us is equally vital. We will follow the principles in keeping with a global and customer-focused presence, which is bolstered by support for the service network.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog