Lasers are a type of machining that uses a powerful light-beam to cut material, wood in this case. The machine is actually quite smart, as it's computer-controlled. These are machines all around us, in plants that produce everyday articles and workshops where designers bash out good quality wooden boards.

These machines come made with the greatest laser technology that lets it generate lethal precise through cuts. This results in unparalleled precision with these cuts, and they are very hard to do even by more common methods such as saws. It turns the wood to gas and then it cuts. It achieves this with the aid of a focused laser beam. They are very accurate and for this reason, they simply DO NOT scar wood nor give you burred edges. For the woodworker who takes pride in their work.

Wood work is as old and frequently practiced but in the modern era of technology, use laser cutting machines have revolutionalized it. Before such machines existed, woodworkers of old had a much more challenging task in making complex shapes and designs. They can be able to cut wood in very systematic and attractive designs because of laser cutting machines. This gives woodworkers another avenue deep into their craft. It allows for them to make their own custom patterns and styles – something that would have been almost impossible with any set of typical woodworking machinery.

Laser cutting machines have been another way to create the possibility of wood bending into different shapes. An innovative approach can be to use another wood. Further, woodworkers can manufacture a unique pattern and form by using different types of woods together. They will of course go towards making the ornament extra beautiful — it just means that you have so many designs at your disposal and a new twist on every one.

This method comes with another exclusive which is a computer program called CAD; this refers to Computer-Aided Design. In this post, we bring you the CAD programs that woodworkers would find handy in sketching their best designs on a computer screen. Laser cutting machines copy their designs onto the wood with accuracy. It very much cuts out the middle man, protecting against human error that can take place even working with hand too but gives woodworkers permission to create exactly what is in their minds.

In addition to larger production-intensive factories, laser cutting machines are also used for small workstations. Wood cnc machines are also becoming increasingly popular with smaller scale woodworkers called 'wood artists' who like to differentiate themselves from the pack. Laser cutters is the most useful tool for these craftsmen in cutting at 90 degree bends not possible with normal wood craft tools used to name and high quality special designs. This gives them the ability to create a unique and improved project for client use.

The biggest benefit to wood artists is that with laser cutting, they can do much faster iterations of their design than via traditional methods. This means they can also create more parts quicker as well. So then they can with this make a little bit more money. More detailed designs and patterns in wood translate to more concomitant crafts which allows you to sell your products at a higher price — increasing the profit.

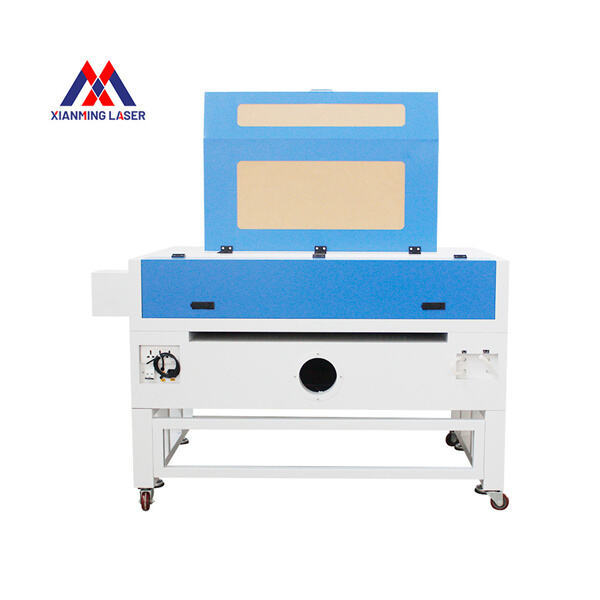

Liaocheng Xianming covers a 30000 place square meters of factory, has an excellent r D team into the field. We are centered on the developing and design for assorted fiber lasers. We have several often patents technical have passed the IS09001 quality management certification system because well as European CE certification plus FDA certification.

Liaocheng Xianming has the ability to provide customers and company logo as well as other custom-designed and customized agents images of the customer's logo, product videos and other media. Our fiber laser machine higher quality than other providers. Our main items are a complete array of high-power metal laser cutting equipment since well as laser welding machine cleaning machine, and co2 engraving machine marking machine.

Liaocheng Xianming machines market and sales network in over 60 countries and areas, has a logistics being professional procedure which provides clients with speedy transportation services so that logistics is manufactured easier. We are going to do our safer to make fully sure your fiber laser machine is delivered efficiently and swiftly, whether you're private business a person.

Liaocheng Xianming gives a lot of attention to after-sales services, knowing that good service fiber laser machines for us is equally crucial. We stick to the principles that are line with customer-centric and global presence. This is made possible by support for the service network.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog