Laser steel cutting machines is such a great innovation whose use has become common among metalworkers, and manufacturers all over. A laser cutting machine works by using a high-powered beam of light to accurately cut through steels, as well asothermaterials, and provides an array of benefits that distinguish it from traditional cutting methods. To their credit, Laser steel cutting machines have a number of advantages. Let us take a closer look at them:

Premium Precision: Laser steel cutting machines are known for top-notch precision and accuracy. One of the best things about laser cutters is their incredible ability to blast through even the slightest and most fragile stuff with tremendous force, which for irrational styles or some exacting designs that demand high tolerances renders them such an excellent choice.

Amazing Versatility- This is one of the most striking features that make laser cutting machines incredibly versatile. They can not only cut through steel, but also aluminum, brass & copper and some plastics. This feature set makes them a valuable asset in any metalworking shop.

There is a Clean and Smooth Cuts: when you use laser metal, steel cutting for clean cuts so that No need any further finishing or polishing. The result is a quality finished product for less time and expense. In addition to that, laser cutting does not leave any burr or unsightly marks which add up the value of the finished product.

High Speed: One of the biggest advantages of laser cutting is how quick it can be. With this speed, you can cut through several intricate patterns in mass-production scenarios, a luxury not every company has at their disposal for complicated designs and tooled dies Traditional cutting systems can be time and labor intensive, but laser based technology performs cuts in a short amount of time. As a result the man power needed to manually cut materials is also eliminated by having this machine do all the work digitally.

Laser cutting is perfect for so many projects and various types of industries. Here are the top uses of laser cutting in lowering several industries:

Signage: Laser-cutting is commonly employed for generating signs prefabricated games outdoor and indoor. This precision is what allows laser cutting to produce intricate patterns and fine lettering in order - it's the perfect method for creating that high-quality showpiece or unique sign.

Laser Cutting Industry) : Laser cutting is pivotal to the manufacture of bespoke brackets, suspension components and engine parts along with custom panels in bodywork within the automotive industry. Laser cutting precision makes it a must in the automotive industry where maximal tolerances can barely be achieved using conventional methods.

Interactive [and] Jewelry Making: Laser cutting is one of the most popular applications among these industries due to its ability to produce complex designs and exact cuts. It is commonly utilized in the creation of custom engagement rings, wedding bands, and various other crafted jewelry that requires a keen eye on every detail.

Distinguished BenefitsThe benefits of laser steel cutting stand out compared to conventional ways in efficiency, precision and cost-effectiveness. Laser Cutters are big time savers when compared to traditional methods as they can complete a task in times that takes other means and reduces material waste thus decreasing costs.

Before you decide on a laser steel cutting machine, there are several factors that could determine the efficiency of operation. One of the most important factors in considering a laser cutting machine is its power output, which defines what kind, and how thick materials you can cut. Furthermore, features such as longevity or automaticity and maintenance are also part of final decision making when it comes to buying the right machine for your metalworking activities.

Laser steel cutting has a great application range in the metalworking industry and this makes it play an extremely important role here. Some of the prominent projects and applications a laser cutting machine saw in various industries:

Laser cutting has a higher preference when it comes to the manufacturing of aerospace components owing its precision and accuracy requirements.

Laser cutting use in Architectural Elements: Laser Cutting is used to produce well-crafted architectural details like Screens, Staircases, Railings and many which add classiness & precision to buildings.

Medical Devices - The medical industry utilises laser cutting for the manufacturing of intricate and complex tools, devices and instruments. Laser cutting is precise enough to allow for very detailed designs, which can be instrumental in producing the types of intricate parts found in critical and medical applications.

Ultimately, laser steel cutting machines make all the difference when it comes to precision, flexibility and speed. That is why they are such a crucial tool for so many metal workers in several industries! The machine you choose depends on your needs in terms of power, durability, level of automation and maintenance required and will open many possibilities for laser cutting projects as well as novel uses in the future.

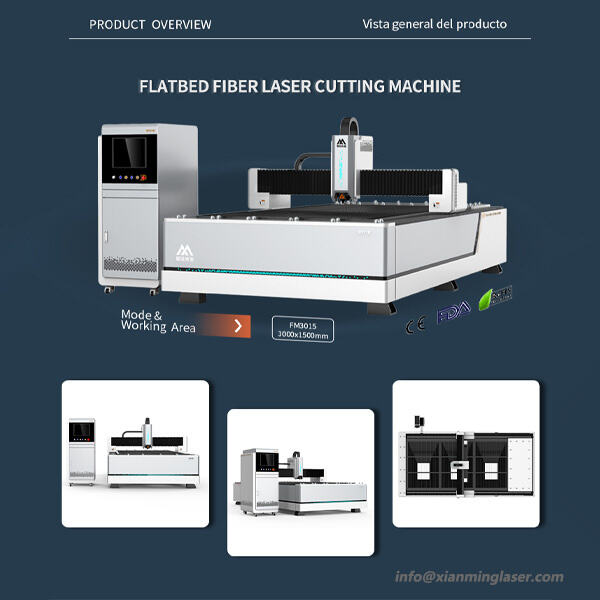

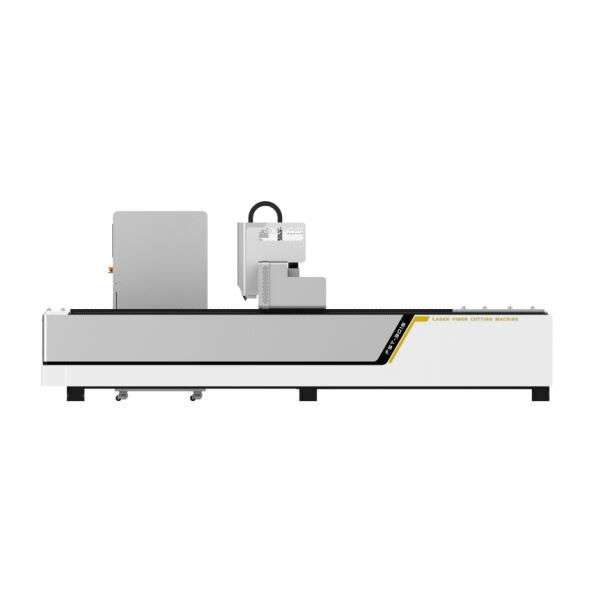

Liaocheng Xianming can provide clients and logos as well since other personalized and agents with images for the customer's logo, product, videos as well as other items. Our fiber laser machine has a top quality than|top quality} other providers, our primary merchandise include a wide range of high-powered metal laser cutting machines, laser welding machine, cleaning machine, and co2 engraving machine and marking machine.

Liaocheng Xianming covers a 30000 location square meters of factory and has now the top r D team the marketplace, and centered on the growth plus creation of various types of fiber lasers. We have a true number of technical patents, and has now completed the IS09001 quality control certification system in addition to European CE certification and Food And Drug Administration certification.

Liaocheng Xianming gives a lot of attention to after-sales services, knowing that good service fiber laser machines for us is equally crucial. We stick to the principles that are line with customer-centric and global presence. This is made possible by support for the service network.

Liaocheng Xianming machines sales plus marketing network that spans over 60 countries and regions. It provides a professional logistics process that provides customers with quick transportation services, making sure logistics gets to be more convenient. Regardless of whether your are the consumer or simply business we are going to endeavour to be the ideal at meeting your needs and acquire the fiber laser machine to where it requires to securely be quickly and.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog