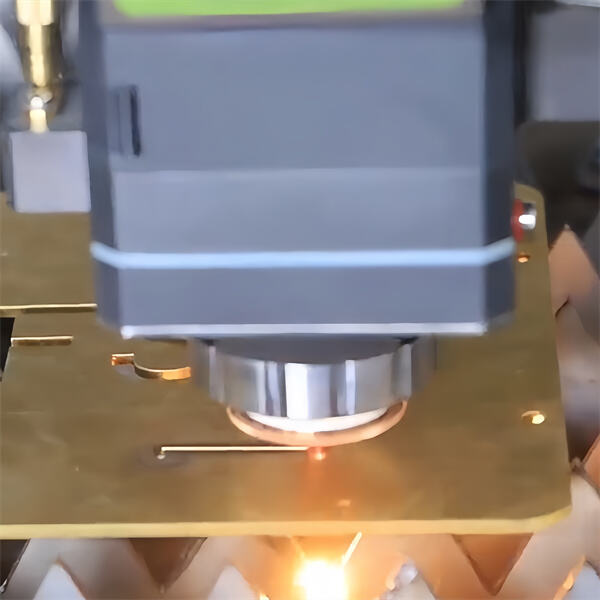

The metal tub laser cutter is an amazing machine which works on a highly concentrated beam of light capable enough to pass through the tubes, and there are no restrictions provided in this case for you may go ahead with producing different shape or size just by shaping itself. This equipment is extremely common in the fabrication and manufacturing sector, used to manufacture all manners of metal products. So in this blog post, I am going to discuss all those amazing features about Using a metal tube laser cutter and how it made Metal as an art cutting.

At its essence, a metal tube laser cutter is an intricate appliance capable of directing a razor-sharp laser beam with near-pinpoint precision to cut any variety of primarily 2D shapes out in any tubing size or thickness. This then ensures you get the perfect cut possible, which means a clean and seamless finish ensuring excellent craftsmanship. Besides, it is a more versatile machine to work in multiple metals such as steel, aluminum or copper.

The metal tube pulsed fiber laser cutter is used in the fields of fabrication & manufacturing

A metal tube laser cutter, at present performs functions that have become conventional in various fabrication and manufacturing sectors, offering the top ways used to accomplish complex designs using sheets of metallic elements. It is so precise, for instance that it can cut through metal exactly as easily and quickly we do paper. Which only means in the hands of their production process toolboxes this-this fiber laser cutting technology never makes anything easier!

Another product used in the automotive industry to build exhaust systems, roll cages and other ingredients of the chassis is Car Metal Tube cutter. Similarly in construction, it is inevitable for supplying the solid frames and beams made of steel across various building. In addition, the sector of furniture would benefit from its know-how in metal frame and legs for tables or seating

An Overview to Increase Productivity with Metal Tube Laser Cutter

Advantages provided by the metal tube laser cutterThe above properties often make a significant difference for businesses, particularly in terms of operations scalability. The high production volumes ensure that large quantities hit the market before they otherwise would have given slower cutting methods. Due to the automation of the laser beam, there is no need for manual process and thus minimal chance of injuries as well operational errors.

Furthermore, these machines can be programmed to cut accurately as shaped designs and styles in a production line; thus minimizing the time between planning of design layout stage until its cutting phase. If done correctly, this can be extremely beneficial for bulk production runs as it aids companies in meeting customer demands and deadlines with a level of consistency.

The emergence of tube laser cutter is so significant that it has almost replaced the traditional drilling and sawing in all areas where cutting related mechanisms should be fast compared to its conservatives which were time taking process. Faster laser processing with high precision enables industry players to scale up their production and ensure more product in less time.

By working with the power of a tube laser cutter, you can also incorporate other design complexities that would have been simply impossible using conventional cutting methods. The differentiation by innovation enables the company to produce heterogeneous products which are not uniform, in contrast with those that competitors deliver.

For this purpose, a smart and cost-effective solution may be to opt for metal tube laser cutter. This allows to diminish the production costs by excluding that additional equipment and manual labour. The waste created when the laser beam cuts is also greatly reduced, again another environmentally friendly aspect.

It needs to pass through various metals like steel, aluminium and copper hence can be used in many industries. This is beneficial as they guarantee that organisations can suit demand for steel assembly products rather than make-up... due to the fact cutting its was meant t be faster and also tact because buildingActivityResult had a physical connection with operations.

A metal tube laser cutter is finally the kind of enabling and shaping machine which has transformed the perception about cutting metals on a whole new level. Its high precision, accuracy and elimination of human error has made laser cutting a powerful tool for many industries helping them lowered the cost to produce goods that have very little defects during operations as well allowing businesses or even non-business individuals who want to innovate in producing more attractive looking products. This is a scalable and efficient solution, which could deliver success to more than one industry sectors alike and help them move towards expansion phase.

Liaocheng Xianming can provide clients and logos as well since other personalized and agents with images for the customer's logo, product, videos as well as other items. Our fiber laser machine has a top quality than|top quality} other providers, our primary merchandise include a wide range of high-powered metal laser cutting machines, laser welding machine, cleaning machine, and co2 engraving machine and marking machine.

Liaocheng Xianming machines market and sales network across significantly more than 60 countries and areas, include a professional logistics procedure which supplies customers with quick transportation services making sure that logistics gets to be more convenient. If you should be a person as an ongoing company we does our far better satisfy your desires and transport your fiber laser machine to its location swiftly and safely.

Liaocheng Xianming pay much pay attention to after-sales services, and know that a good after-sales service and high quality fiber laser equipment is same important for us will adhere to the principles of keeping with the global, customer-focused presence bolstered by the support of service networks, and it will offer 24/7 on-line service. We will strive to offer the customers with more superior products and superior service.

Liaocheng Xianming has a 30000sqm manufacturing unit. We want the top r D department in the industry, therefore we look at the creation of various kinds of fiber lasers.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog