Two metal pieces can be joined together with the help of a little machine, known as mini laser welding machines. In addition to taking up less space, the laser is more powerful and capable of both fast "containment welding" over long distances as well as fine-grained cutting.

Miniature Laser Welding MachineThere are times when a mini laser welding machine is called upon; compact as it may be, it is still mighty. This machine throws a laser beam that heats up to levels such high it melts metal. Since the metal is melted with a laser beam, it creates an ultimate bond.

Tiny parts can now be welded using a mini laser welding machine. It's kinda like having a super power that allows you to the fix something once broken.

Using a mini laser welding machine takes practice, you will need to learn how to properly hold and aim the laser. However, with time and practice; anyone can master welds in no time. Safety protocols must be followed and protective gear should be worn to prevent any burns from the laser.

In addition to metal there are also mechanical rabbets that it can weld, as in the case of brass but less so steel and aluminum. It is best used instead on a mini laser welding machine, which perform both readjustments even when repairs at high speed. The beauty of it is that you are not only able to fix small items like jewelry or eyeglasses but even build entirely new ones such as custom metal parts for your machines.

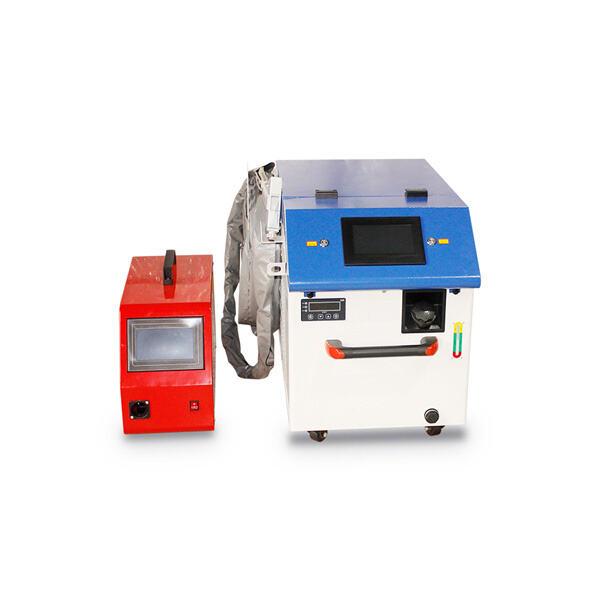

A new type of mini laser welding machine, low-cost and portable welder developed by MORN LASER with intelligent operation system. These machines are useful in many industries like automobile, aeronautics and even jewellery making.

In the automotive sector, small parts can be repaired with mini laser welding machines such as sensors or connectors. In aerospace, they are used for repairing engine parts or fuel systems. Moreover, they are employed in the jewelry trade as mini laser welding machines to make or repair intricate work.

So finally, laser welder mini makes a powerful machine for those who have the applications and parts to justify using it. Yes it takes some time to really get down but with persistence, anyone can become proficient at making perfect welds. The popularity of mini laser welding machines has been on the rise among different industries because they are compact, convenient to work with and high in efficiency. This remarkable technology has the potential to repair or even remake things that were previously thought irreparable.

Liaocheng Xianming machines marketing and sales network spread across a lot more than 60 countries and regions, has a professional logistics process provide customers with quick transportation service therefore that logistics can be made more convenient. We are going to try everything to make sure that your fiber Laser machine reaches its destination efficiently and swiftly, regardless if you are a private person a small business.

Liaocheng Xianming is very attentive to after-sales and support services, knowing that having excellent service for fiber lasers for us are equally vital. We stick to the principles that are the spirit of customer-centricity and global presence. This is made possible through support for our service networks.

Liaocheng Xianming covers a location of 30000 square meters factory is home to an outstanding r D team in the business enterprise. These are typically dedicated to the development and creation of numerous kinds of fiber lasers. We now have several patents that could be technical. We've been awarded the ISO9001 quality management system certification and european CE certification certification.

Liaocheng Xianming offers customers with customized logos and videos, images and other materials. Agents are also able to incorporate customer-branded things. Our fiber Laser machine is much better to other manufacturers.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog