Ever seen a tool that can wield a laser beam to cut wood? It almost sounds like it belongs in a sci-fi movie, but this is real and incredible! A plywood laser cutter is a specific device for engraving wood on many different levels of rate and precision. This is especially cool if you are working on projects that require the exact cut of of a component, which allows this machine to be able create really detailed and precise shapes from wood.

We are not joking when we say our life seemed totally different after laser technology began to cut plywood. In the past, before laser machines were invented, people had to use their saws and manual tools in cutting woods. This was a long, slow process and the cuts were not always perfect or true. When the cuts were not straight it just made using jigsaws more difficult to complete tasks properly. With laser cutting, Plywood can be cut much easier and more accurately. This fresh cutting manner lets us craft gorgeous designs into plywood which were high priced, complicated or maybe unfeasible to make earlier. Your imagination is the limit when it comes to a laser cutter!

Accurate cuts are really important when it comes to cutting plywood. BUT if your cuts are not straight the whole project is going to be wasted and never look right. A Plywood Laser Cutting Machine Ensures Your Cuts Are Always Perfection This ensures a very fine beam that allows for almost surgically cutting through the plywood without energy loss — meaning you can make elaborated designs inside of them with less chance to fail. This means, you get to dedicate more time developing your creative concepts than counting on whether or not the cuts will be perfect.

The main advantage of the laser cutting service is that they are way faster than your usual manually operated machines, apart from just being accurate. For a laser cutter you can cut through plywood in just minutes, but it would take longer and more effort if done manually! Particularly vital for businesses that need to churn out large quantities of plywood products in as little time possible, this speed is constant throughout the entire run; within seconds after processing only a few sheets you will not be beholden to secondary drying. At the end of the day, time is money and completing tasks quickly will make sure your businesses customers are satisfied quicker and that even more products can be made in a shorter space of time.

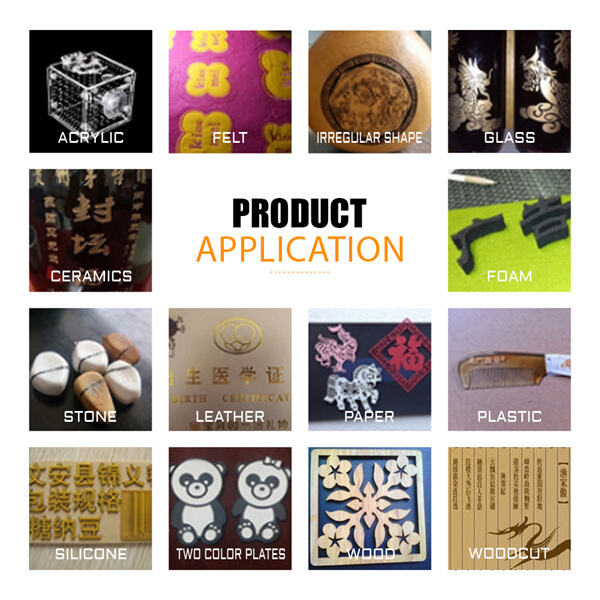

One of the greatest benefits that come with having a plywood laser cutting machine is its versatility in terms of cuts. It allows you to make straight lines, curves and other shapes which are inconvenient for traditional tools. And to give extra beauty touch, you can cut some layer of the plywood and put it on down side as engraving art to your project, checkout pic 4. This is great for companies and hobbyists that can make their unique, custom implementations to differentiate themselves from the competitors. Signs, toys, or home decor; this machine will do the work in which you need it to.

Liaocheng Xianming Machines provide a professional packing was logistic built to provide fast transportation services for customers and making logistics easier. We are going to try our easier to ensure that your fiber Laser machine reaches their destination quickly and safely, irrespective of no matter whether you are an ongoing company an individual.

Liaocheng Xianming gives customers and custom logos plus images, videos as well as other materials. Agents are also able to deliver customized things by customers. Our fibre laser machine is preferable to other manufacturers.

Liaocheng Xianming has a 30000sqm manufacturing unit. We have a top r D department within the industry, and now we concentrate on the creation of several types of fiber laser machines.

Liaocheng Xianming Pay close focus on after-sales support, know that a good after-sales service and high quality fiber lasers are equally important to us will adhere to the principles of in line with the global, customer-focused presence that is enhanced through service network support and will be 24-hour online service, try best to provide our customers with superior products and better service.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog