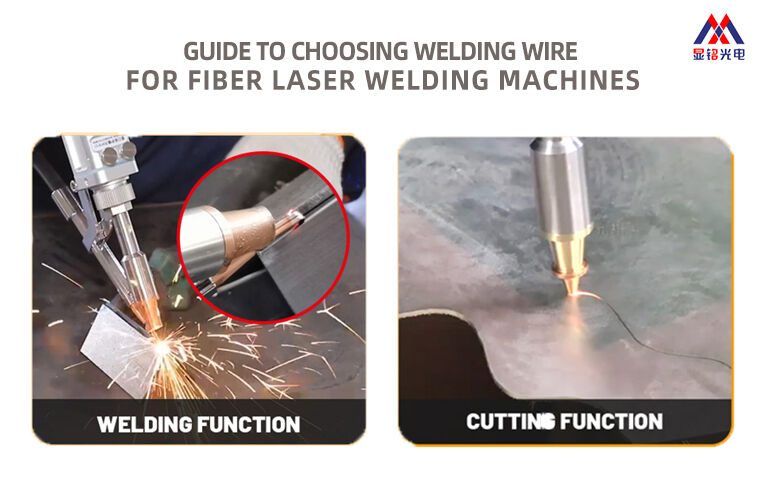

Guide to Choosing Welding Wire for Fiber Laser Welding Machines

In laser welding processes, welding wire is a critical filler material that directly affects weld appearance, joint strength, and overall welding quality. Selecting the right welding wire helps improve welding stability while reducing common defects such as spatter and porosity. This article explains key principles for choosing welding wire for laser welding machines.

Step 1: Match the Base Material

Step 1: Match the Base Material

Choosing the right filler wire starts with knowing your base metal. Proper metallurgical compatibility ensures strong, corrosion-resistant welds and reduces the risk of cracks or separation.

| Base Material | Recommended Filler Wire | Description |

| Stainless Steel (304) | ER308 | Composition-matched, excellent corrosion resistance, attractive weld appearance |

| Carbon Steel (Q235) | ER70S-6 | Contains Mn and Si, strong deoxidation, low spatter |

| Aluminum Alloy (6061) | ER4043 | Silicon-based, good crack resistance, excellent flowability |

| Aluminum Alloy (5083) | ER5356 | Special for magnesium alloys, high strength, corrosion resistant |

| Brass | HS221 | Dedicated for brass, good thermal conductivity |

| Dissimilar Metals | Al-Si alloy or other transition wire | For welding dissimilar metals (e.g., steel-aluminum), prevents cracking, process testing required |

Step 2: Check the Thickness — Thin Sheet, Thin Wire; Thick Sheet, Thick Wire

Step 2: Check the Thickness — Thin Sheet, Thin Wire; Thick Sheet, Thick Wire

Plate thickness determines the ideal wire diameter. Using the right size ensures proper fusion and fill.

(The following data is for reference only. Adjust according to your actual situation.)

| Plate Thickness | Recommended Wire Diameter |

| 0.5–1.5 mm | 0.8 mm wire |

| 1.5–3.0 mm | 1.0 mm wire |

| 3.0–4.5 mm | 1.2 mm or 1.6 mm wire |

| ≥ 3 mm (high filler demand) | Optional dual-wire feeder (e.g., dual 1.0 mm wires) |

Tip: For thick plates or wide joint gaps, use thicker wire or dual-wire feeding for efficient fill and joint strength.💡

Step 3: Calculate Power — Match Wire Size with Laser Output

Step 3: Calculate Power — Match Wire Size with Laser Output

Wire melting behavior depends on laser power. Proper pairing prevents burn-through, cold lap, or spatter.

| Filler Wire Diameter | Recommended Laser Power |

| 0.8 mm | Around 1000W |

| 1.0 mm | 1500W–2000W |

| 1.2–1.6 mm / Dual Wire Feed | 2000W–3000W or higher |

Using high power with thin wire can cause burn-through or unstable arcs. Xianming Laser machines offer smart power control, adjusting output automatically for optimal results.⚠️

Step 4: Inspect the Wire — Choose "Triple-Clean" Wires

Step 4: Inspect the Wire — Choose "Triple-Clean" Wires

Wire quality directly impacts weld stability. Choose wires with the following three "NOs":

✅ No Oil: Surface should be clean—test with alcohol; cotton stays white

✅ No Rust: Wire should have a bright silver or metallic color

✅ No Coating: Copper-plated wires must have <0.5% copper to avoid overheating or spatter

📦 Always store wires in sealed, dry conditions to avoid oxidation and moisture absorption.

Reference:

Reference:

Common Welding Wire Characteristics

| Model | Characteristics | Application Recommendations |

| ER308L (High Si) | Improves weld pool flow for stainless steel, excellent crack resistance | Suitable for welding 304, 316 stainless steel |

| ER4043 (Si Alloy) | Crack-resistant and good flowability when welding aluminum alloys | For welding 6061, ADC12, and similar aluminum materials |

| ERCuAl (Aluminum Bronze) | Specially for copper alloys, high strength and excellent wear resistance | Copper valves, electrode plates, etc. |

| ER1100 | Tensile strength up to 1100 MPa, ideal for high-strength structures | Welding of special equipment |

| ERNiCr-3 | Nickel-based alloy wire, excellent high-temperature corrosion resistance | Petrochemical and nuclear industries |

| ER316L | Ultra-low carbon stainless steel, food-grade corrosion resistance | Food containers, medical devices |

Why Use Xianming Laser Machines for Wire Feeding?

Why Use Xianming Laser Machines for Wire Feeding?

Xianming Laser’s welding systems fully support 0.8 mm–1.6 mm wires, offering:

Automatic wire feeding laser welders

Automatic wire feeding laser welders

Dual-wire feeding laser welding machine

Dual-wire feeding laser welding machine

Smart seam compensation

Smart seam compensation

Our systems are ideal for welding thin sheets, thick plates, aluminum, brass, or dissimilar metals, widely used in hardware, kitchenware, sheet metal, and aluminum products.

Conclusion

Conclusion

Although welding wire is a small component, it plays a vital role in laser welding performance. By selecting the correct welding wire and combining it with proper welding parameters, laser welding machines can achieve high efficiency, precision, and consistent weld quality across various applications.