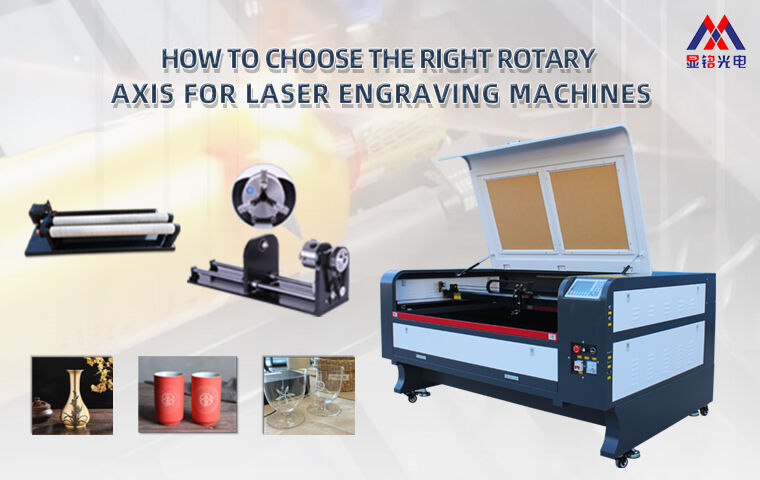

How to Choose the Right Rotary Axis for Laser Engraving Machines

In laser engraving and laser marking applications, a rotary axis is an essential accessory for processing cylindrical and round objects. Choosing the right rotary axis based on engraving accuracy, workpiece type, and budget can significantly improve processing efficiency while controlling overall costs.

At Xianming Laser, we provide different rotary axis solutions to match various laser engraving and marking machines, helping users achieve stable, efficient, and precise rotary processing. The most commonly used rotary axes can be divided into two main types: dual roller rotary axis and three jaw chuck rotary axis.

Dual Roller Rotary Axis

Dual Roller Rotary Axis

Product Overview

Product Overview

The dual roller rotary axis uses a roller friction transmission structure, where the workpiece rotates through its own weight and roller compression. No additional clamping device is required. With a simple and lightweight design, it is easy to install and operate, making it ideal for entry-level users.

Key Advantages

Key Advantages

Low cost: Simple structure with fewer components, resulting in lower initial investment

High-speed operation: Friction-driven rotation ensures high transmission efficiency

Simple and lightweight design: Easy installation and quick setup

Low maintenance cost: No complex or fragile components

Supported Workpiece Range

Supported Workpiece Range

Diameter range: approximately Ø10–300 mm (no fixed limit)

Adjustable roller spacing allows compatibility with various cylindrical sizes

Clamping and Transmission Method

Clamping and Transmission Method

Roller friction drive

No three-jaw chuck required

Workpieces are fixed by roller compression

Gentle surface contact, minimizing scratches and surface damage

Suitable Workpieces

Suitable Workpieces

Cylindrical and smooth-surface objects

Glass cups, wine glasses, tumblers

Metal tubes and coated cylindrical products

This type is especially suitable for uniform, high-volume batch engraving.

Target Users and Applications

Target Users and Applications

Beginners and entry-level laser users

Gift shops and customization businesses

Applications focused on mass production and retail sales

Compatible Motor Power

Compatible Motor Power

Standard NEMA17 stepper motor (42 mm)

Power range: 40W–80W

Maintenance Cost

Maintenance Cost

No easily damaged structural parts

When rollers wear out, only the rubber rollers need to be replaced

Simple maintenance with minimal downtime

Three Jaw Chuck Rotary Axis

Three Jaw Chuck Rotary Axis

Product Overview

Product Overview

The three jaw chuck rotary axis features a high-precision chuck structure, providing strong clamping force and excellent concentricity control. It is designed for professional applications requiring high engraving accuracy.

Key Advantages

Key Advantages

High-precision processing capability

Strong clamping force for stable positioning

Ideal for precision engraving and laser marking of small or complex parts

Chuck Specifications

Chuck Specifications

Available models: K11-80 / K11-125

Supported Workpiece Range

Supported Workpiece Range

Diameter range: approximately Ø2–125 mm (non-fixed limit)

Suitable for small and multi-size precision components

Clamping Method

Clamping Method

Three-jaw chuck clamping

Ensures forced concentricity

Supports both inner hole and outer diameter clamping

Suitable Workpieces

Suitable Workpieces

Precision inner-hole components

Eccentric workpieces

Small metal parts

Recommended for high-precision and complex processing requirements.

Target Users and Applications

Target Users and Applications

High-end customization services

Industrial laser marking and engraving

Users who prioritize accuracy, stability, and professional performance

Compatible Motor Power

Compatible Motor Power

Standard configuration: NEMA17 stepper motor (42 mm)

Power: 40W–80W

Heavy-duty configuration: NEMA23 stepper motor (57 mm)

Power: 120W–200W

Maintenance Cost

Maintenance Cost

Chuck jaws and bearings are wear parts

Regular lubrication and inspection are required

Maintenance cost is higher compared to roller rotary axes

Rotary Axis Selection Summary

Rotary Axis Selection Summary

If your application focuses on smooth cylindrical objects, large batch production, and low investment, the dual roller rotary axis is the ideal choice.

If your work requires high precision, small parts, eccentric engraving, or inner-hole clamping, the three jaw chuck rotary axis is the better solution.

Xianming Laser rotary axes are fully compatible with laser engraving machines equipped with NEMA17 stepper motors. For applications requiring higher load capacity and torque, NEMA23 rotary axis solutions are also available and can be integrated simply by adding the appropriate driver unit.

By choosing the right rotary axis, Xianming Laser helps you improve engraving quality, production efficiency, and overall laser equipment performance—ensuring reliable results for both commercial and industrial laser applications.