Laser Welding Machine Focus Adjustment: How to Achieve Precision Operation

In modern manufacturing, precision and efficiency are critical to ensuring product quality, and laser welders plays a key role especially in welding processes. One essential but often overlooked step in laser welding is focal distance adjustment. Regardless of the type of laser welding machine you use, setting the correct laser focus is crucial to achieving strong, clean, and consistent welds.

So, how can you quickly and accurately find the correct focus distance? In this article, we’ll walk you through a simple and practical three-step method.

What Is Laser Welding Focal Distance?

What Is Laser Welding Focal Distance?

The focal distance refers to the vertical distance between the laser’s focus point—where the beam converges into the smallest spot—and the surface of the material being welded. When the material surface aligns precisely with this focal point, the laser energy density reaches its maximum, resulting in optimal weld quality.

Why Is Accurate Focus Adjustment So Important?

Why Is Accurate Focus Adjustment So Important?

Laser welding relies on the principle of concentrated energy at a single point. If the laser beam is not correctly focused on the material surface, energy is dispersed ineffectively, which can lead to:

Weak or incomplete welds

Excessive spatter and material deformation

Burn-through or surface discoloration

Decreased welding speed and accuracy

Proper focus maximizes energy delivery to the weld zone, which is particularly important in high-speed welding applications using optical fiber laser welders,portable laser welder or automated laser equipment.

Three-Step Method to Adjust Laser Focus

Three-Step Method to Adjust Laser Focus

Step 1: Check the Red Light Alignment

Step 1: Check the Red Light Alignment

- Remove the wire feeding tube for easier access.

- Detach the nozzle at the laser head to expose the beam path.

- Project the red guiding light onto a stainless steel plate, black card, or copper sheet.

- Observe the light—a clear and even red dot indicates a proper beam path, while dark spots may suggest misalignment or contamination.

- A distorted or uneven red light spot often indicates mirror or lens issues.

Step 2: Inspect and Replace Lenses

Step 2: Inspect and Replace Lenses

Check the following optical components in sequence:

- Protective lens (most likely to be dirty or damaged)

- Focusing lens

- Reflective mirror

- Collimating lens

Disassembling the reflective and collimating lenses should only be done by professionals or with guidance from the manufacturer.

If no obvious issue is found, try replacing the protective and focusing lenses first—coating defects or contamination may affect laser transmission quality.

Step 3: Adjust the Focus Distance

Step 3: Adjust the Focus Distance

Use the machine’s focus scale or Z-axis to set different heights incrementally.

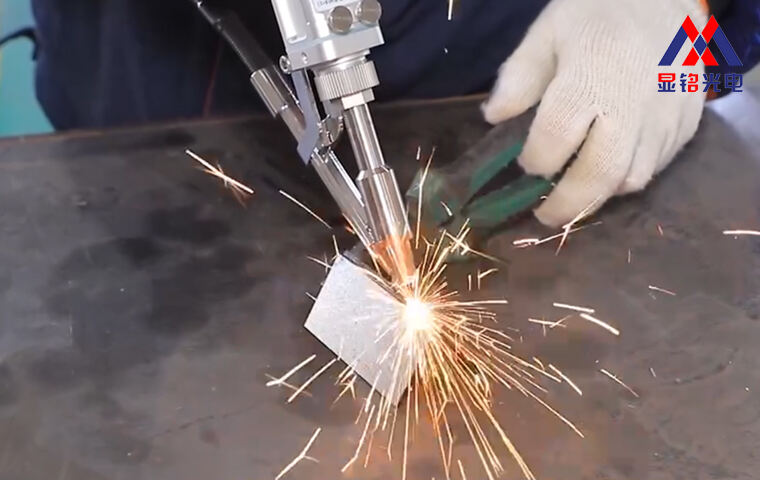

Test each height by triggering the laser to observe spark size and weld seam quality.

The correct focal distance will produce:

Bright, stable sparks

Smooth and even weld seams

Minimal spatter

You can also listen to the welding sound: correct focus results in a clean and steady sound, while incorrect focus often produces harsh or inconsistent noises.

Final Step: Reassemble and Begin Welding

Final Step: Reassemble and Begin Welding

Once the optimal focus has been identified, reinstall all parts including the wire feeder and protective components. You can now begin your standard welding operations. For different materials or thicknesses, minor adjustments may be necessary to maintain optimal welding results.

Summary

Summary

Accurate focus adjustment is not a one-time setup, but a continuous process that ensures your laser welding system delivers the best performance. By mastering focus control, you can:

Improve weld strength and appearance

Minimize welding defects and rework

Increase operational efficiency and consistency

If you're looking to further optimize your laser welding equipment—whether a soldadora laser or an optical fiber welder—don’t hesitate to contact Xianming Laser. We provide professional technical support, operator training, and customized solutions tailored to your production needs.

Email: [email protected]

Email: [email protected]

WhatsApp/WeChat: +86 15314155887

WhatsApp/WeChat: +86 15314155887