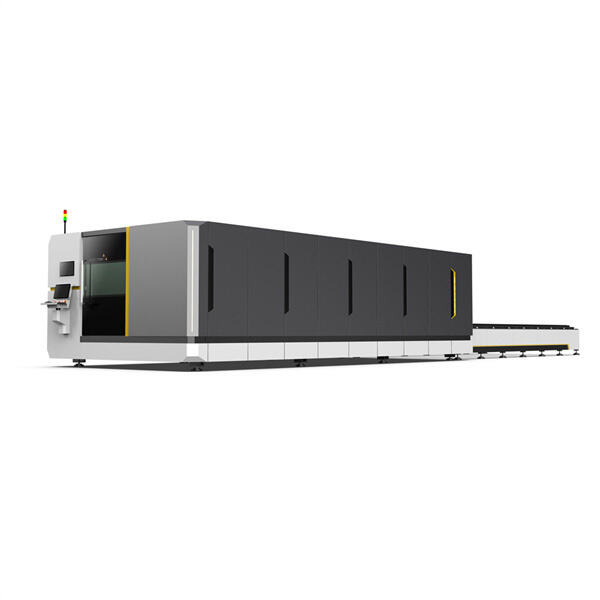

Fiber laser cutting machines are known to be situated at the top of the manufacturing scale in various industries. Enclosed fiber laser cutting machines are very popular because they can give precise cuts with less human effort. For manufacturers enclosed fiber laser cutting machine is a way to achieve unprecedented level of productivity and accuracy.

Comparison between enclosed and tube fiber laser cutting machine and advantages of each

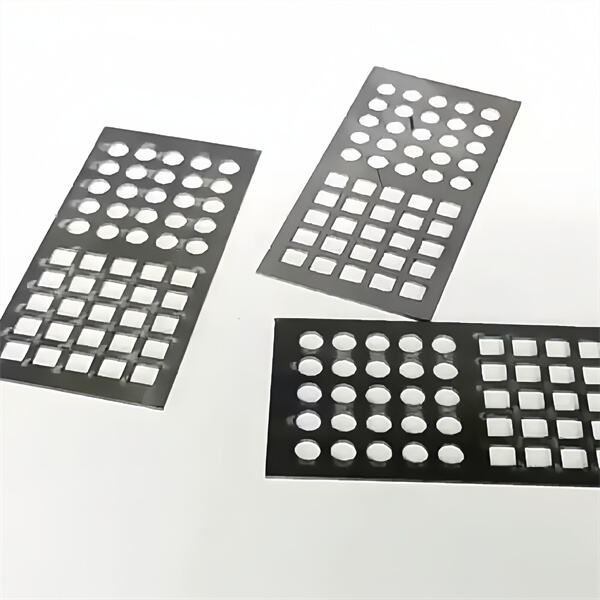

These will enable more accurate cuts as opposed to those normal cuttings that you do traditionally every other ordinary day. Coupled with ever-advancing software and these covered cutter converters, which provide nearly zero set up time exactly, they too can quickly produce even intricate shapes correctly.

Another big added advantage is that it has flexibility yet again making it one of the advantages associated with these enclosed fiber lasers. This Liaocheng Xianming fiber laser cutting machine operates by successfully cutting metals, plastic as well as composites in different thicknesses. This range of enclosed fiber lasers for carving out shapes or contouring objects has been quite versatile across several materials, such as those needing precision chops.

Future Directions for Safety and Efficiency with Fiber Laser Cutting Machines

Laser cutting technology has changed dramatically over the years, and some examples include enclosed fiber laser cutters. In practical terms this represents perhaps one of the biggest advances recently made in these devices when it comes to safety. Moreover, there are built-in automatic safety mechanisms in case the enclosure is opened on any side during its operation.

For instance, due to a nearby sensor that can detect an operator’s presence adjacent to where metal is being processed by this apparatus. At once the whole device stops functioning if anything gets near or into this press preventing injuries from happening. Additionally, such covering fiber lasers for carving have a fume extraction system installed, which completely removes gas or dust from art work precision construction thus operators avoid health risks involved.

Moreover most covered fiber lasers frequently come equipped with computer aided design (CAD) and computer aided manufacturing (CAM). By using this sophisticated Fabrication CAD Software, an operator can easily program and make complex shapes with the maximum possible level of accuracy in a relative minimum of manual work. These technological advancements are therefore significant for enclosed fiber laser cutting machines and must be considered in whatever is manufactured!

Manufacturing techniques are constantly being changed by fiber laser cutting machines. In addition, these devices save time for the manufacturers who use them to make quick and accurate cuts, hence cost savings. Construction teams also can complete their projects faster through reduced manual labor allowing products to get into the market quickly.

In addition, it has a large output power that allows non-metallic material processing as manufacturers can engage in small-volume mass production. The Liaocheng Xianming compact fiber laser cutting machine is able to run automatically is designed so businesses scale up from one bracket earning greater income all through.

If you are in the process of purchasing, this article can help you make a decision regarding your requirements for Fiber Machine.

How to choose the fiber laser cutting machine, several elements need to be considered. To begin with, how good is your machine laser at producing power. The higher wattage ones can cut through thicker materials like any other cutting machines that have been made before – therefore its selection should depend on what kinds of materials are nearby.

Also, check on the size of the cutting space. Each equipment will have a natural cutting table size which might differ from others (hence not all limits are set by the same).

Finally do not neglect also consider buying cost and how much it would cost you down-the-line with maintenance and up keep. Enclosed fiber laser cutting machines can carry a heavy price tag which discourages small scale operations but saves money in long run though. Well, you should ensure that this machine falls within what you can afford and also make sure that its maintenance cost is manageable.

Which Fiber Laser Cutting Machines Should I Chose?

Choosing an enclosed fiber laser cutting machine (or sheet metal processing plant) is no small matter for calming yourself at night over. Making these decisions - which should work best for you depends on what types of jobs are typical in your unique operation here’s some of things to consider: Laser power Cutting area size Total price in short just do a bit research on different manufacturers/suppliers for lowest price.

In Short, fiber laser cutting machine is a new era in manufacturing industry. This provides clients with unparalleled precision, flexibility, and productivity across various industrial applications. However former options where fiber laser cutting machines had to utilize gas-type enclosures as part of operator safety initiatives so as to deliver increased performance were less cost-effective than energy expenses required at production facilities. By selecting appropriate equipment manufacturers could increase productivity levels and maximize their business profits.

Laser cutting is a technology that has seen amazing advancements over the years, and enclosed fiber laser cutting machine have not been far behind. This is one of the areas in which many improvements have been done on these machines i. e. safety. Additionally, modern enclosed fiber laser cutting facilities come with unmanned safety features as well as those that are embedded in them.

They have got sensors for example that can establish if there is an operator within this cutting zone. Anytime a worker comes near such equipment; it stops short at once to prevent injury or anything bad from happening. Also, enclosed fiber laser cutting machines have an exhaust system of fumes for removing all gases and dust from the making process where personal arts or precision was used which alleviate operators work hazard.

Another improvement in enclosed fiber laser cutting machines is that they often have computer-aided design (CAD) and computer-aided manufacturing (CAM). This powerful CAD software enables operators to program and manufacture complex shapes with maximum precision and minimal manual input. Consequently, these technological innovations have led to a significant increase in the safety of enclosed fiber laser cutting machines with improved productivity thus worthy considering for any manufacturing operation.

Fiber laser cutting machines are changing manufacturing forever. These machines can achieve fast and accurate cuts saving time for the manufacturers hence saving costs as well. They speed up projects by reducing the need for human effort thereby shortening time to market.

In addition, it should be noted that a fiber laser cutting machine enclosed also has an opportunity to operate on many big orders and be able to work on higher quantities of material so as for manufactures may produce reduced scale production. Revolutionary machines can be used automatically, effectively non-stop operation for more profits and large-scale business growth.

Here are some tips which may help you decide on the right fiber laser cutting For Fiber Machine

Choosing a fiber laser cutter ought to involve several considerations. First, consider how much power your machine’s laser can emit. When it comes to such cutters, lasers of higher wattage can cut thicker materials; therefore, make sure your choice caters perfectly for your most used material.

Similarly, examine your workspace dimensions too: The bed size in a machine is critical because specific sizes of objects should fit into what other people would usually cut with their frameworks (and some do not).

Lastly, look at initial costs associated with purchasing such equipment as well as its maintenance cost over time. Nevertheless, despite their high upfront price tag these enclosed fiber laser cutting wonders could save money in future but take care about the expense implications at first. Ensure this follows one’s pocket capability while considering the Liaocheng Xianming best fiber laser cutting machine.

Having so many to choose from can make it very difficult for someone to decide on which enclosed fiber laser cutting machine they should get. Determine the best choice for your specific operations Some of the things that you need to consider when making this decision are laser power, size of the cutting area and cost. Take time to research the different manufacturers and suppliers you are considering so that you can get the best deal possible.

To sum up, fiber laser cutting machines have completely transformed how things are made in factories. They offer unequaled precision, adaptability and capacity across a wide range of industrial applications. With advances in technology and even safer lasers today, enclosed fiber laser cutting machines have become much more secure yet rewarding – at a cheaper production cost level. When choosing a machine, manufacturers should consider their overall productivity since this can elevate them into higher levels.

Liaocheng Xianming has a 30000sqm manufacturing unit. We want the top r D department in the industry, therefore we look at the creation of various kinds of fiber lasers.

Liaocheng Xianming machines market and sales network across significantly more than 60 countries and areas, include a professional logistics procedure which supplies customers with quick transportation services making sure that logistics gets to be more convenient. If you should be a person as an ongoing company we does our far better satisfy your desires and transport your fiber laser machine to its location swiftly and safely.

Liaocheng Xianming produces customers with personalized logos plus videos, images and other materials. Agents also provide customized items by customers. Our fiber laser machine tend to be more advanced than more manufacturers, our main services and products include a wide range of high-powered metal laser cutting machines laser welding machine, cleaning machine, and co2 engraving machine, marking machine.

Liaocheng Xianming Pay close time to after-sales customer service, understand that quality service and quality fiber laser machines is same important for us to adhere to the principles of keeping with our customer-centric, global presence that is enhanced by service network support, and will be 24-hour on-line service. We will strive to offer the our customers with superior products and superior service.

Copyright © Liaocheng Xianming Laser Co., Ltd. All Rights Reserved. - Privacy Policy - Blog